CW Blog

Sensors for Composites Processing: CW Trending Episode 8

Why use sensors in composites manufacturing? What sensor types are available and how can they be applied? Learn about all of this and more in a discussion with CW senior editor Ginger Gardiner and editor-in-chief Jeff Sloan in this episode of CW Trending, sponsored by RVmagnetics.

WatchSensors: Data for next-gen composites manufacturing

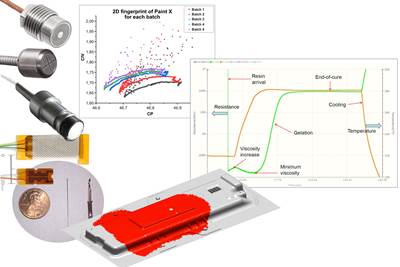

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

WatchPredicting and mitigating failure in composite parts

Understanding the complexity of composites manufacturing resides in studying the design challenges inherent to fabrication, as much as the physics aspect. To serve this effort, CW introduces a new column, “Predicting Failure.”

Read MorePlant tour: Victrex Composites Solutions, Bristol, Rhode Island, U.S.

De-risking thermoplastic composites at industrial scale via hybrid overmolding.

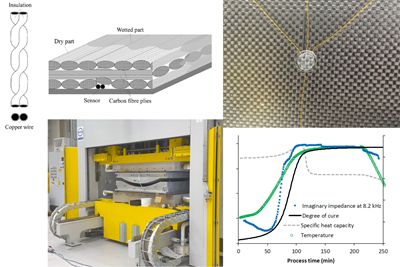

WatchNational Composites Center and Meggitt demonstrate linear dielectric sensor for liquid composites processing

Research at Cranfield University is further developed via RTM part trials in NCC’s Technology Pull-Through Program

Read More