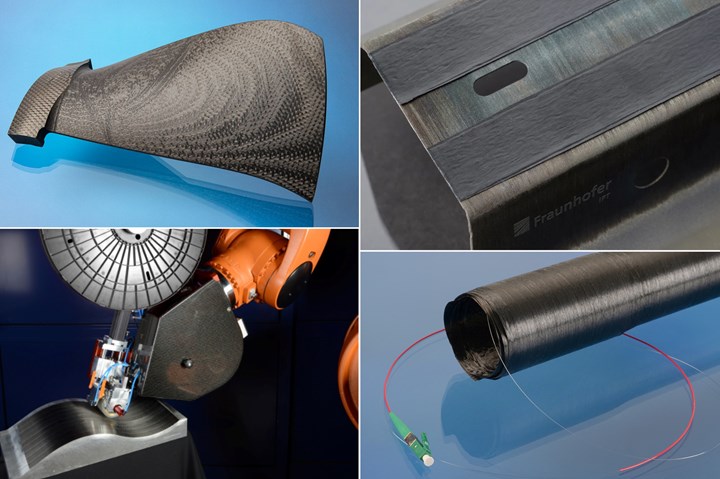

Fraunhofer IPT development includes (clockwise from top left) thermoplastic composite aeroengine fan blades, hybrid composite-metal structures using laser structuring and AFP, structural health monitoring (SHM) of composites and thermoplastic composite tape processing systems, such as the PrePro 2D and PrePro3D systems commercialized by Conbility. Photo Credit: Fraunhofer IPT

In December 2020, I published an article on how the Fraunhofer Institute for Production Technology (IPT, Aachen, Germany) is developing fully automated tape laying and forming for thermoplastic carbon fiber-reinforced polymer (CFRP) aeroengine fan blades. In-situ consolidation (ISC) of thermoplastic composite tape, it turns out, is a topic that Fraunhofer IPT knows well, having driven this technology at its beginning together with ISC pioneers Accudyne Systems Inc. (Newark, Del., U.S.) and Automated Dynamics, now Trelleborg Sealing Solutions Albany (TSS Albany, Niksayuna, N.Y., U.S.). [For more on these ISC pioneers, see “Consolidating thermoplastic aerostructures in place, Part 1 and Part 2”.] “The IPT has been active in laser-assisted tape winding (LATW) since 1988, and it remains one of our main topics,” explains Dr. Henning Janssen, chief engineer and department head for fiber-reinforced plastics and laser system technology at Fraunhofer IPT. He notes that LATW technology has changed a lot, especially in the last 10-15 years. This blog gives more details about Fraunhofer IPT’s development of LATW and of thermoplastic composites more broadly, as well as where the institute sees the technology headed in the future.

Evolution in laser tape winding

“When we started 30 years ago, laser technology was not ready for high-speed processing of thermoplastic composites,” says Janssen. “You can imagine that, especially on the control side, you only had an analog camera. Now, we have much better technology. For example, when we developed a compact laser winding head in 2008, which resulted in the founding of AFPT Germany (Dörth, Germany), we had to use a 16-pixel x 16-pixel camera, which offered a frame rate of only eight frames per second. Now, we easily have 640 x 480 pixels and processing of 50 frames or more per second.” He explains that this is important, “because with the laser tape winding that we have developed, one of the main advantages is that you can look into the process and also change the processing power within milliseconds. That gives you a good advantage, for example, as you go around complex geometries, such as the dome of pressure vessels, where the winding speed slows down, and you must lower the laser heating power. You then must readjust as the winding regains speed along the tank cylinder. This wasn’t possible 15 years ago because the laser, control system and thermal imaging technologies were not ready or were too expensive and also not as powerful as what we have today.

Janssen continues, “So, there's a lot that has developed on the digital side. Now, for example, we supply something like a digital twin, where you can map all your sensor information onto the pressure vessel, so that you can compare the part as manufactured versus the digital design to assess part quality and predict performance. Using virtual process sensors and models also enables us to predict the laminate strength as defined by its processing history.” This is important because LATW using thermoplastic tape uses fast heating and cooling where the material and part properties are determined during the winding process itself, due to the lack of a thermal post-processing step, he notes. It’s critical, therefore, to have the ability for rapid process control.

There have also been developments in materials, says Janssen. “Twenty years ago, there was a limited amount of thermoplastic composite tape materials available, such as APC-2 from Cytec, which is now Solvay (Alpharetta, Ga., U.S.),” he explains. “But now, many more materials are qualified for industrial applications, and you also have a lot of commodity materials like polypropylene (PP) reinforced with carbon fiber and also with glass fiber, as well as polyamide six (PA6), for example, which is used quite a lot in the automotive industry. There are also now applications for LATW which are more toward mass production. For example, there's a push toward retention sleeves and other parts in electric motors. These are simple thermoplastic composite rings or tubes, but in volumes of 10,000 to 50,000 per year.”

ambliFIBRE, pipes for oil and gas

Part of the digital control in LATW that Janssen describes above was developed in the ambliFIBRE project (2015-2018). “There were many partners in that project,” he says, “but one was Baker Hughes (Newcastle, England and Houston, Texas, U.S.) and we used our LATW equipment for their nonmetallic pipes.” Note that shortly after ambliFIBRE ended in 2018, Baker Hughes announced its joint venture with Saudi Aramco (Riyadh, Saudi Arabia) to expand the use of nonmetallic pipes, including the possible use of carbon fiber-reinforced plastic (CFRP).

Baker Hughes is now aiming to speed up the introduction to non-metallic materials in the energy sector,and there are other companies using laser based technology for pipe as well, such as Magma (Portsmouth, U.K.). (See “Thermoplastic pipe on the rise in the deep sea” and “Magma Global delivers high-pressure composite riser…).

“It is also quite common to use laser tape winding for thermoplastic composite risers and flowlines as well,” says Janssen. “Although this is not common knowledge in other industries yet.” He adds that much of the recent attention given to LATW has been for hydrogen storage tanks, but the technology already has a much broader application.

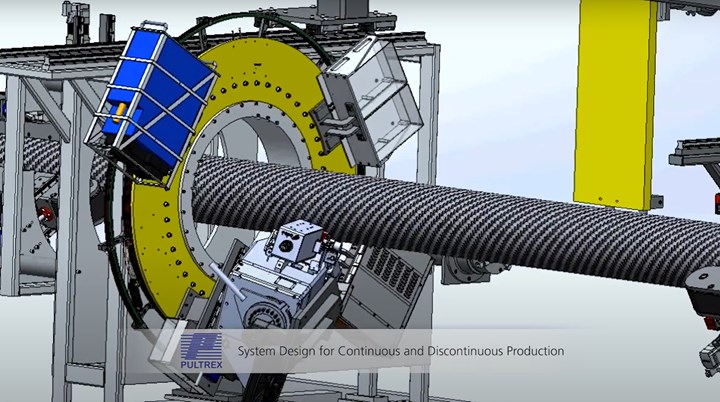

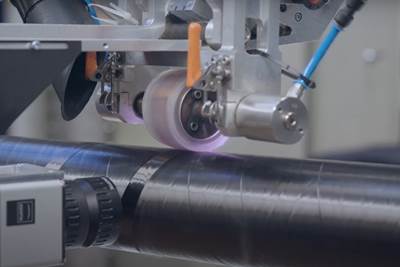

Within the ambliFIBRE project, Fraunhofer IPT developed digital process control models for discontinuous (e.g., tanks) and continuous tape winding, for example, to produce pipes several kilometers long. Photo Credit: Fraunhofer IPT video for ambliFIBRE project

“And what we at Fraunhofer IPT offer for these applications is key,” says Janssen. “Obviously, we’re not running a full-scale production line for continuous pipe production here in our institute, but what we do offer for our customers is material testing and product qualification. There's the testing pyramid, for example, based on DNV-GL F114, starting with qualification and testing of the polymer and the fibers, and then scaling up to the composite laminate microstructure or mesostructure. So, we do a lot of testing at the coupon level, and then scale to smaller pipes and representative pipes, for example, because winding gives you different properties than pressing or automated tape laying (ATL).”

Also, he notes, “because you have different stresses in your material, a lot of these composite materials are tested in smaller pipes, for example 2-3 inches up to several meters long. So, we do this testing and then we apply our process understanding for the real part length, for example 2-3 kilometers. And that's very interesting, because processing time at that length may span a couple of days, and you must consider shrinkage as well as other factors, such as changes in ambient air temperature, which can have quite an impact.”

LATW in hydrogen storage tanks

Janssen says Fraunhofer IPT has worked with oil and gas companies since 2000. “And then, eight years ago, we figured out this is nearly the same technology which you need for hydrogen tanks,” he recalls. “And now we have a big initiative for hydrogen manufacturing here at IPT and also for carbon fiber composites in fuel cells. We are setting up an 80-million-euro facility for automated fuel cell manufacturing and are also investing in a new, quite large winding facility so that we can produce parts up to 7 meters long and 2.5 meters in diameter, which we will also use for large pressure vessels.”

As part of the “tank cycling” project, Fraunhofer IPT is developing processes and industrial equipment for recycling thermoplastic composites including, for example, future pressure vessels. Photo Credit: Fraunhofer IPT

LATW using thermoplastic composite tapes is not yet state-of-the-art for pressure vessel manufacturing, says Janssen, “because the chemistry of the thermoplastics, as well as its processing and durability are all still being researched. But our strong belief is that the low permeability, toughness and recyclability that thermoplastics offer is important.” He also sees potential for thermoplastics in Type V pressure vessels, which are all-composite but do not use a separate thermoplastic liner. “These may provide a future solution for some mobile hydrogen storage applications, such as fuel cell electric trucks.”

“We also see that conventional thermoset filament winding is limited regarding minimum winding angles,” says Janssen. “For example, you have to go around the domes in helical layers with not much less than a 10° fiber angle. So, you can't put a 0° reinforcement into a conventional filament wound tank.” However, he contends, “in classic LATW, the incoming thermoplastic prepreg is directly welded to the substrate, so you can go in any direction you want, which gives you much more design freedom. We are currently running projects with partners from the automotive industry for developing thermoplastic pressure vessels for hydrogen storage which are safe, energy efficient and easy to recycle.”

Thermoplastic composite fan blades

Fraunhofer IPT has a very strong background in turbomachinery, says Janssen. “We have here in Aachen the International Center for Turbomachinery Manufacturing, or ICTM, a pre-competitive community where we are working with the engine manufacturers and their suppliers jointly in pre-competitive R&D projects to develop and enhance manufacturing technology.”

He notes that in the last 20 years, the focus has been mainly in machining of titanium or nickel-based alloys for advanced products of the compression section and turbines, such as the blade integrated disk (blisk). While in the cold section, parts out of composite materials — such as carbon fiber composite fan blades — were developed by GE in the 1990s and are now in service in the GE90 and GEnx. “Now, however, ceramic matrix composites (CMC) are seen as next-generation materials for the hot section of jet engines,” says Janssen, “enabling higher temperatures at less weight for greater efficiency.”

“The manufacturing of parts from composites compared to metal is very different,” he continues. “In metal, you start with a bulk of material and derive the part by subtractive processing, mostly machining, so that the design is not so dependent on the manufacturing. It is just the opposite in composites, which always require some sort of generative process. So, we decided that we will address novel fan blade strategies from a manufacturing perspective.”

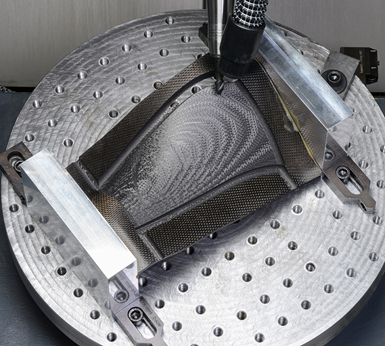

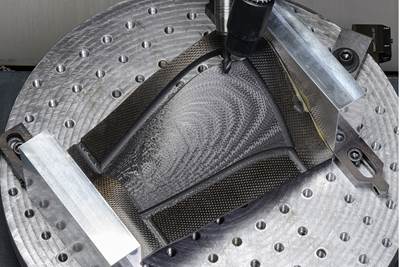

Fraunhofer IPT is developing automated tape laying, thermoforming and machining of thermoplastic composite fan blades for aeroengines. Initial trials, shown here, included 16-mm-thick carbon fiber-reinforced PA12 organosheets and has now proceeded to PEEK and PAEK laminates. Photo Credit: Fraunhofer IPT

He also notes the Clean Sky 2 joint undertaking, in which Fraunhofer is leading the Eco-Design activities. Fraunhofer IPT is focusing on the eco-design for engines, which includes lifecycle assessment and evaluating the environmental impact. “This is why we have begun to look at thermoplastic composites,” he explains. “So far, we are at a very low TRL [technology readiness level]. For now, the development is about manufacturing and trying different process routes, such as near net shape lay-up and a bit of thermoforming — which is more like a calibration step — and then the finishing in terms of machining. So, there is quite a lot of work ahead of us yet.”

Meanwhile, Fraunhofer IPT is extending its expertise in machining metal aeroengine components to composites, using its digital technology to monitor and assess the machining parameters on every blade. But isn’t the goal in composites to move away from such subtractive manufacturing to more additive manufacturing for less waste? “Yes, but for some process routes, machining is required to meet dimensional tolerances,” says Janssen. “What we are working on right now is very near net shape.”

He points out that the design being developed currently is a 0.75-inch-thick thermoplastic laminate at the root and only 2-millimeters thick at the tip. “And then there are different design strategies, which we discuss together with the design engineers. Also, do you have an autoclave or a press step for that kind of very highly-loaded part? This will also play a role regarding the internal stresses, because we know that this blade is twisting a bit during rotation. And, of course, bird strike is a key issue.” For the latter, Janssen sees the increased toughness of thermoplastics as an enabler, pointing out PPS (polyphenylene sulfide) composites are used in wing leading edges for this very reason.

Future applications for thermoplastic composites

I asked about the possibility to use thermoplastic composites in engine nacelles, which could perhaps help provide a solution to four recent blade-out incidents, where, as reported in a March 2021 Aviation Week article:

“… damage caused by blade fragments hitting sections of the engine’s covering, or nacelle, triggered a series of events that caused large pieces of structure, including parts of engine inlets and fan cowls, to break away.” In all four accidents, the aircraft fuselage suffered damage, and for Southwest Flight 1380 in April 2018, one of the windows was dislodged, causing a passenger fatality.

“There is some interest from industry to make use of thermoplastic composites in engine compartments,” says Janssen, “however, this is a long-term development.” One issue for such a development is certification by aviation authorities, another area where Fraunhofer IPT is active. “We are now discussing with certification bodies how to help reduce the certification effort by proving digitally that new manufacturing processes conform to current and evolving standards. So, that's a new way of thinking. In 21st century manufacturing, there is so much data available, it’s not just about certifying one process or one design by testing, and then that is frozen.” In other words, today’s emphasis on Industry 4.0 and Composites 4.0 is that sensors and AI-enabled software will continuously gather data and develop intelligence that will then continuously optimize manufacturing and, in turn, send that intelligence backward in the digital thread to improve designs. This is indeed very different from today’s manufacturing.

Fraunhofer IPT develops processes and systems — e.g., in situ tape laying (top) — that enable dry fiber and thermoplastic composite tapes (as well as thermoset prepreg tapes) to be processed on an industrial scale. Photo Credit: Fraunhofer IPT

Fraunhofer IPT’s work regarding certification, says Janssen, “could help enable new technologies such as thermoplastic composites for engine parts — that is, once all aspects, including technology, design and risk management, are considered.” He asserts that thermoplastic composites offer huge potential to help overcome key challenges in a variety of industrial sectors, and notes that Fraunhofer IPT is working to overcome the processing complexity of thermoplastic composites — for example, making use of newly available digital manufacturing methods. “Furthermore, the potential of thermoplastic composites can only be fully exploited once the full life cycle — including re-use and recycling — is considered,” says Janssen. “Thus, Fraunhofer IPT is also working on mechanical recycling of thermoplastic composites. We see it will be possible to achieve high-value recycled material by considering both the data generated during manufacturing and that generated during the whole life cycle of composite components.”

Related Content

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

Challenges of laser-assisted tape winding of thermoplastic composites

Practical solutions for process-related challenges in LATW, which has great potential for pressure vessels and storage tanks.

Read MoreFraunhofer IPT automates production of thermoplastic CFRP engine fan blades

Successful first demonstrations on 16-mm-thick CF/PA12 to be followed by CF/PEEK tapes and embedded sensors for structural health monitoring (SHM).

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More