CW Blog

Developing new solutions for noise, vibration and harshness

Several recent IACMI partner projects focus on technology innovation related to challenges in noise, vibration and harshness (NVH) in vehicle design.

Read MoreCombination of automation, rigid foam core enable high-volume aircraft part production

A feasibility study demonstrates increased production capacity using Evonik foam core and automated manufacturing.

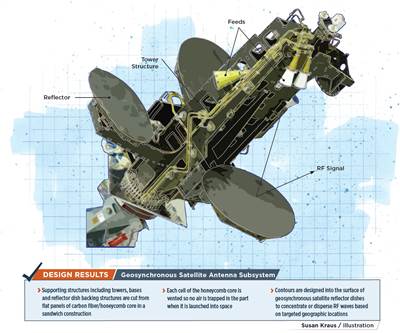

Read MoreTooling, precision enable composites in satellite subsystems

Tight tolerances drive design and engineering of large-format composite component and dishes to create unique satellite structures.

Read MoreContinuing the sustainable composites conversation

Once the coronavirus pandemic ends, and a new “normal” begins, what will the conversation around sustainable composites and advanced materials sound like?

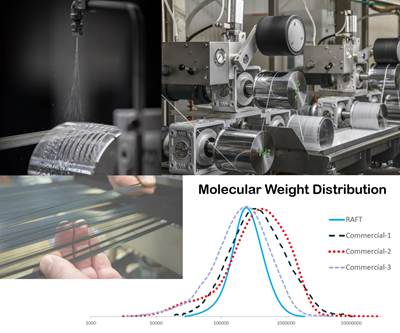

Read MoreCSIRO: Developing higher-quality, higher-strength, lower-cost carbon fibers

SIROPAN precursor aims for >20% increase in carbon fiber properties with increased control via RAFT polymerization, FLOW processing and novel metrology.

WatchPolypropylene honeycomb lightens, strengthens automotive panels

Polypropylene honeycomb cores from ThermHex are used by Brazilian OEM DPA Moldados to make the trunk floor of the Hyundai Creta ix25.

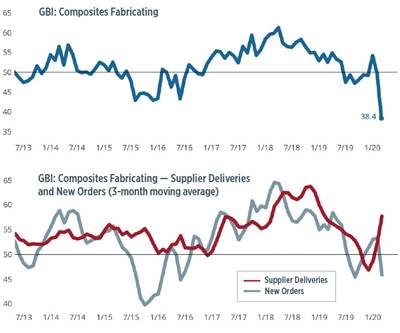

Read MoreComposites Index contracts as COVID-19 disrupts economy

March 2020 Index falls to historic low as domestic and foreign orders activity weakens.

Read MoreThe evolution of composites in NASCAR

The growing role of carbon fiber in stock car racing.

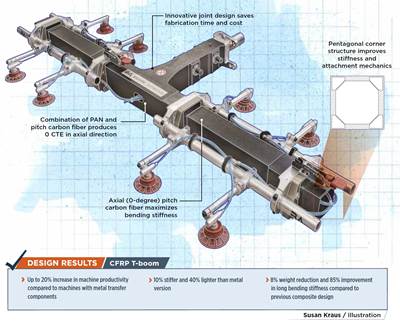

Read MoreComposite T-boom accelerates industrial automation

A manufacturing method that integrates filament winding with axil winding of 0-degree fibers opens new design options in industrial automated equipment.

Read MoreHexcel materials, distribution partner selected for Gunboat 68 yacht

A range of Hexcel HiMax carbon fiber multiaxials and PrimeTex spread tow woven fabrics enhance an all-carbon-fiber luxury catamaran.

Read More3D printing large composite molds with a 5-axis CNC machine

Hungarian manufacturer uses CEAD Robot Extruder to cut composite tooling time and cost.

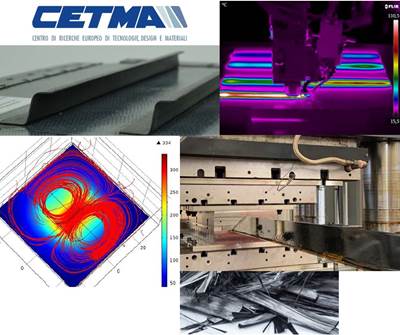

WatchCETMA: composites R&D and innovation in Italy

From design and simulation to inline inspection, induction welding, continuous compression molding and recycled carbon fiber, this lab to support industry is advancing composites in aerospace, automotive, construction and more.

Read More