CW Blog

Racing to build tomorrow’s automotive composites workforce

Recent graduates share experiences gained from collegiate automotive design, engineering and motorsport competition Formula SAE.

Read MoreSatellite deployer redesign supported by 3D-printed composites

A Scottish technology company employs additive manufacturing and CRP Technology composite materials for a lighter, more manufacturable PocketQube deployer.

Read MoreWhen — not if — to pivot

In the business and manufacturing world that CW operates in, we have heard one particular coronavirus vocabulary word very frequently: pivot.

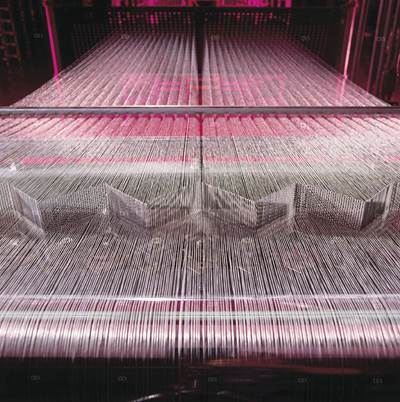

Read MoreThe making of glass fiber

The old art behind this industry’s first fiber reinforcement is explained,with insights into new fiber science and future developments.

Read MoreComposites speed concrete facade fabrication

The 45-story One South First building, on the 11-acre Domino Park campus in Brooklyn, N.Y., features a geometrically complex concrete facade made, in part, with composite molds fabricated using large-format additive manufacturing.

Read MoreCoriolis Composites and Edixia develop inline inspection for AFP

Video and discussion of how the sensor and software operate to boost composites productivity

WatchFiberglass composites improve infrastructure efficiency and sustainability

Gert de Roover, building, construction and infrastructure manager at Exel Composites, explains why composite materials contribute to the drive for greener buildings.

Read MoreHyperjoint: additive metal + composites = stronger, tougher joints

Eliminates drilling holes with lap shear 60% higher than bolted joints and almost twice that of bonded joints.

WatchChanging composites paradigms in the wake of COVID-19

Efforts to locally and globally collaborate in order to address industry issues and stimulate innovation are becoming essential conversations during the coronavirus pandemic.

Read MorePlant tour: Hexcel, Salt Lake City, Utah, U.S.

The scale, precision, speed and quality of carbon fiber manufacture has evolved substantially since the material’s modern introduction in the late 1960s. Hexcel offers a glimpse of the state of the art today.

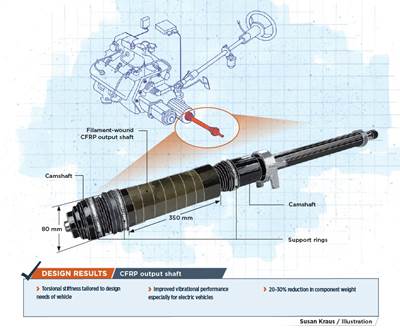

Read MoreComposite output shaft ready for automotive proving ground

Unlike automotive driveshafts, automotive output shafts cannot leverage shaft length as a factor when making the case for composites. Instead, other beneficial features have made a composite output shaft able to compete with metal shafts, especially in electric vehicles.

Read More