CSIRO: Developing higher-quality, higher-strength, lower-cost carbon fibers

SIROPAN precursor aims for >20% increase in carbon fiber properties with increased control via RAFT polymerization, FLOW processing and novel metrology.

The Commonwealth Scientific and Industrial Research Organisation (CSIRO) is Australia’s national science agency that is developing the next generation of carbon fiber. Specifically, its researchers aim to control both the molecular structure of polyacrylonitrile (PAN) precursor and its processing to produce carbon fiber that is higher quality, more affordable and higher performance. “Only 10% of the theoretical strength for carbon fiber has been achieved so far,” notes Andrew Abbott, CSIRO team leader carbon fiber. “Strength is mainly limited by defects in the fiber surface and microstructure, as well as impurities in the precursor,” explains Tony Pierlot, CSIRO project leader fiber metrology. “Controlling the structure of the precursor can improve carbon fiber strength.”

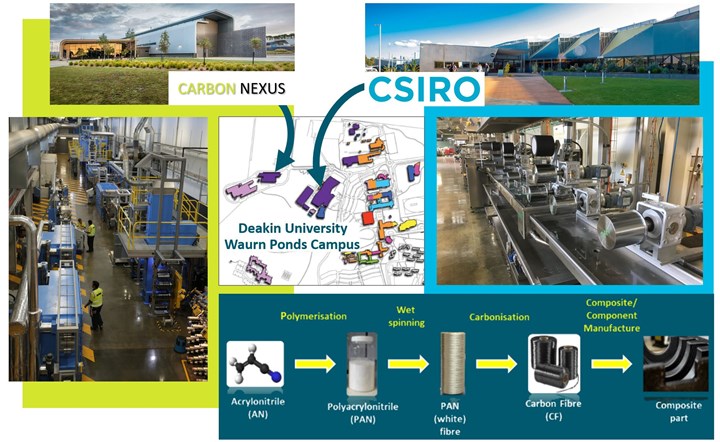

In 2017, CSIRO launched its own wet-spinning line to manufacture PAN precursor, working in collaboration with Deakin University’s Carbon Nexus facility (which launched its carbonization line in 2013). CSIRO and Carbon Nexus are part of Deakin University’s Waurn Ponds campus in Geelong, roughly 75 kilometers southwest of Melbourne. These groups are working with the local composites industry as part of the Advanced Fibre Cluster Geelong, which includes well-known composites manufacturers such as Carbon Revolution and Quickstep — also located on the Waurn Ponds campus — as well as GMS Composites, Sykes Racing, ACS Composites and others.

Carbon Nexus (left) focuses on the last steps of carbon fiber production, including oxidation and carbonization, while CSIRO (right) focuses on the first steps including polymerization and spinning of PAN precursor. Together, the whole carbon fiber process chain is being revolutionized at Geelong (bottom right). SOURCE | ArchDaily.com, Carbon Nexus, CSIRO, Geelong, collated by CW.

“CSIRO’s work is centered around the first steps in carbon fiber production, including the polymerization of acrylonitrile into polyacrylonitrile and then spinning and further processing PAN to produce a higher-quality and cheaper precursor fiber,” explains Abbott. PAN production accounts for 50% of carbon fiber’s cost but 70-90% of its properties. “Deakin University’s technology involves the final steps in carbon fiber production, including oxidation and carbonization,” he continues. “The technology they have licensed to LeMond Composites (Oak Ridge, Tenn., U.S.) is for rapid oxidation aimed at lowering the cost of these final steps.”

To achieve its goals for next-generation carbon fiber, CSIRO is using a set of strategic tools: RAFT polymerization, FLOW chemistry processes and CarbonSpec metrology. “Our aim is to produce an aerospace-grade carbon fiber with 20% higher strength,” says Abbott, noting the team hopes to have some initial results by the end of 2020.

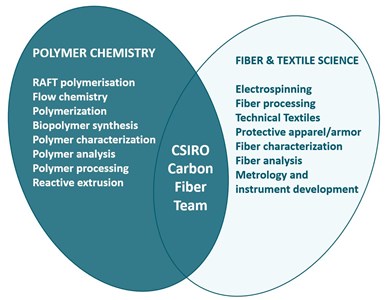

CSIRO carbon fiber team

The carbon fiber team combines CSIRO’s expertise in polymer chemistry and technical textiles. SOURCE | CSIRO, edited by CW.

With 5,000 employees, 55 sites, eight business units and a budget of roughly $1 billion, CSIRO projects span a wide range of topics — e.g., 3D printing, biopolymers, medical implants, smart apparel, astronomy/space exploration — and involve more than 2800 partners each year. “CSIRO invented and patented Wireless LAN,” explains Abbott, “and uses that revenue to fund other research.”

One of its 55 sites is in Silicon Valley, Calif. CSIRO US connects Australian researchers with USA projects to expedite scientific advancements in areas such as space, agriculture, water conservation, wildfire and smart cities. The goal is open innovation partnering which brings together deep research competencies as well as experience with a wide range of real-world problems.

“In composites, CSIRO develops new resins and processing techniques,” he continues. “We also do a lot of work in modeling of composites and process simulations as well as measuring carbon fiber properties. For example, we have developed new instruments to measure the transverse modulus of carbon fiber, which we then input to improve our modeling and simulations.”

“CSIRO has a 30-year strategic relationship with Boeing,” says Abbott. “We were recognized as Boeing’s technology supplier of the year in 2016 and 2017.” CSIRO’s carbon fiber team also collaborates with the University of Southern Mississippi (Hattiesburg, Miss., U.S.).

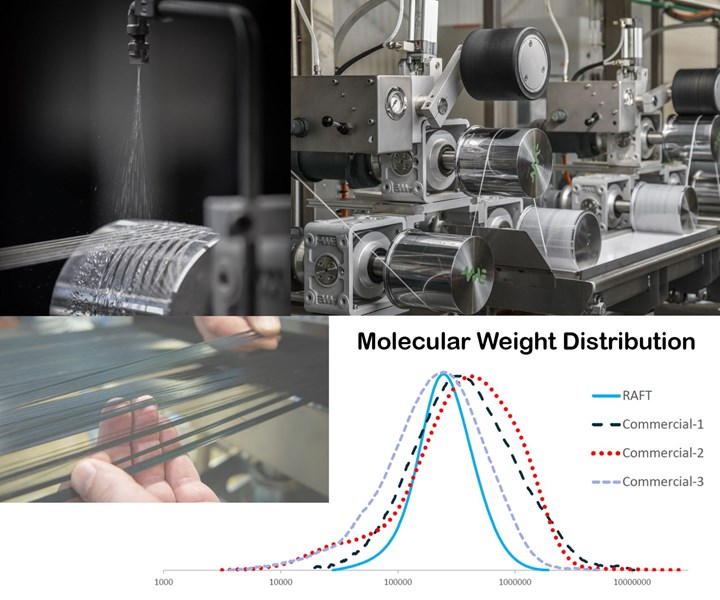

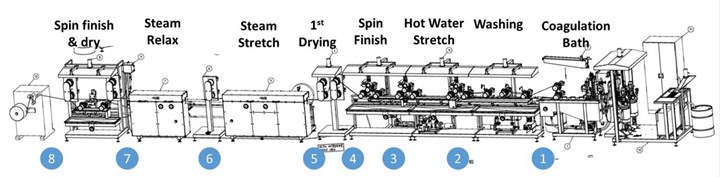

Wet spinning pilot line

CSIRO’s wet spinning line, including hot water spraying (top left) and rollers for controlled stretching. SOURCE | CSIRO

In order to complete the necessary research in carbon fiber precursors, CSIRO first had to establish its own wet spinning line. “Carbon fiber is only made by a handful of manufacturers around the world, each of whom hold their own secret, patented recipes,” explained CSIRO chief executive Dr. Larry Marshall at the 2017 launch of the new line. The pilot line was custom built by MAE (Fiorenzuola d'Arda, Italy), a machine manufacturer which specializes in polymer and fiber process equipment. “It is designed like a commercial line but at a smaller scale,” explains Abbott.

In a CSIRO blog, the line’s workings are described using the analogy of making pasta. Similar to dough used to make pasta, a polymer solution called dope is used to spin PAN precursor fiber. Just as pasta dough is kneaded and then pressed through a die to make long, thin strands of spaghetti, dope is mixed and then coagulated and spun through multi-holed spinneret to produce 500 to 12,000 separate strands of PAN fiber — all finer than human hair. These fibers are washed, stretched on rollers, stabilized in a series of solutions, steamed and dried before being spooled for the carbonization line at Carbon Nexus.

SOURCE | CSIRO

“It has taken us a long time to fully understand how to make carbon fiber and the precursor feedstock,” says Abbott. “No one really wanted to help us, so we had to learn mostly on our own. Now, however, we have complete control over the precursor process, which is key, and then we work with Carbon Nexus for the carbonization.”

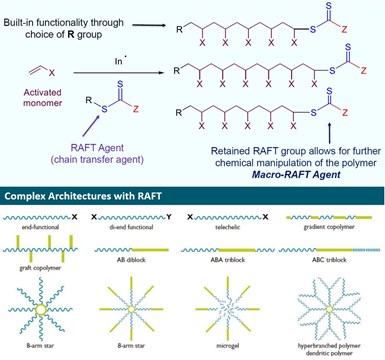

RAFT polymerization

RAFT provides more control over polymerization, including polymer size, composition and architecture. It enables reactive terminal groups in the polymer backbone for added functionality as well as complex architectures such as graft, star and gradient polymers. SOURCE | CSIRO, Boron Molecular

Another tool CSIRO is applying is its patented and commercialized RAFT(Reversible Addition-Fragmentation chain Transfer) technology. RAFT is a sophisticated form of controlled free-radical polymerization that enables the synthesis of tailored polymers with unprecedented control over composition and architecture. Though applications for RAFT range from novel drug delivery systems to industrial lubricants and coatings, CSIRO’s carbon fiber team uses it to exert control over the PAN polymerization process.

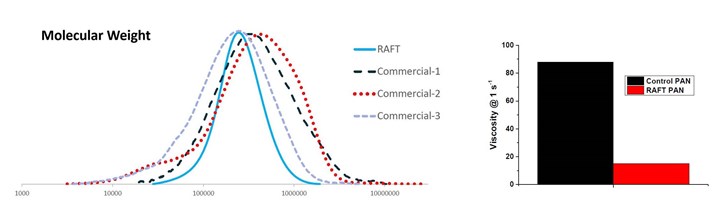

“Conventional polymerization from monomer to polymer produces a broad polydispersity — in other words, a lot of different lengths for the polymer chains,” explains Melissa Skidmore, CSIRO team leader polymer chemistry. “If we add a RAFT agent, however, we now get polymer chains of almost the same length, and thus a much narrower molecular weight distribution. We are still using the same initiators, monomers and solvents but just adding RAFT.”

“Molecular weight affects the viscosity of the spinning solution,” says Skidmore. “Traditionally, higher molecular weight in dope solutions has led to grooved surfaces on the precursor fibers. Adding RAFT decreases viscosity of the dope solutions, leading to a higher solids loading. Removing the very high molecular-weight polymer of the polymer may result in better molecular alignment in the fiber and improved properties.” She adds that low molecular weight has a plasticizing effect on fibers. “RAFT produces PAN polymers which could produce denser, more uniform precursor fibers with fewer structural defects. This could also help speed carbonization and lower cost.”

RAFT produces PAN polymers with better controlled molecular weight, as seen here in the narrower distribution (left), which results in an overall higher molecular weight dope but which is also lower in viscosity (right) vs. current commercial PAN. SOURCE | CSIRO.

“This also gives us access to complex polymer architectures,” notes Skidmore. “RAFT allows for further chemical manipulation of the polymer group.” An example of where that comes in handy is when the dope solution is manipulated to coagulate into fibers. “There is a delicate balance between the ideal characteristics of the dope polymer solution and coagulation conditions,” she adds. “The polymer is 95% PAN and 5% additives. Because RAFT polymers behave differently, we think we can lower some of the traditional additives and convert a higher percentage to high-solids fiber, which leads to less defects. We are testing this now.”

Though not currently the main focus, RAFT is also extremely interesting for its ability to add functionality during polymerization. For example, researchers have been looking at how to make composites with a high adsorption capability for CO2 capture (i.e., CO2 would adhere to the composite’s molecular surfaces). Multifunctional composites are already being sought after by aircraft and electric vehicle manufacturers. New types of PAN and carbon fibers with added functionalities could become an important solution for future composites.

Continuous FLOW process

“With RAFT, we gain control over polymerization,” says Abbott. “With FLOW, we have more control over the fiber formation.”

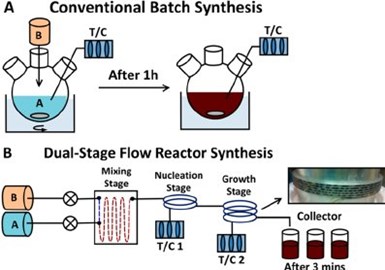

Example of batch vs. flow reactors for polymerization. SOURCE | Figure 1, “Automated Synthesis of Photovoltaic-Quality Colloidal Quantum Dots Using Separate Nucleation and Growth Stages” by Jun Pan, et. al.

FLOW converts polymerization to a continuous rather than a batch process. Abbott and Skidmore explain that the batch reactors used currently are well-established, easy to set up and efficient in mixing and monitoring the reaction kinetics, but they also require a larger volume than continuous process reactors, meaning industrial-scale set up is expensive. These larger-volume batch reactors are also inefficient regarding space and energy consumption. Continuous process reactors are smaller and less expensive, easy to scale, more energy-efficient and offer superior process control and better reproducibility vs. batch processing. However, because they are a dedicated, continuous line, they are less flexible in switching between different parameters and products.

There are also safety and sustainability benefits. “Right now, PAN production is environmentally unsustainable, especially with regard to toxicity,” says Skidmore. “Making the polymerization process continuous improves safety, because the reactive agents that are toxic, odorous, and flammable are isolated and handled by automated equipment. However, this will increase complexity of the lines, which do require a higher degree of monitoring and control.” Though it will require further development, Abbott sees FLOW polymerization as a positive: “Carbon fiber is inherently variable, so anything you can do to reduce this variability improves the properties.”

CarbonSpec – measure to manage

The final tool in CSIRO’s carbon fiber approach is CarbonSpec. “It’s basically metrology we have developed to test the fibers we produce and better understand the property-material relationship,” explains Pierlot. “If you can’t measure it, you can’t improve it. We are also better able to predict carbon fiber properties from a minimum amount of PAN and carbon fiber measurements.”

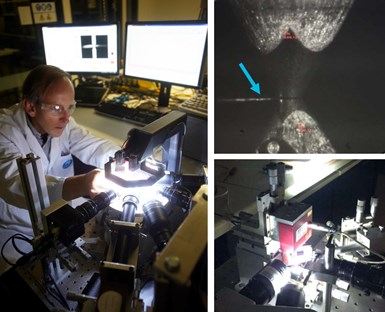

CarbonSpec is the CSIRO carbon fiber team’s metrology to understand and predict fiber properties, including the creation of new methods and instruments to measure transverse and compression properties. SOURCE | CSIRO

“In the carbon fiber industry, it’s standard to use synchrotron X-ray computed

tomography (CT) to determine the microstructure of your fibers,” says Pierlot. (A synchrotron is a football field-sized particle accelerator that generates very bright X-rays which are directed to an adjacent beamline for imaging, etc.) “With the assistance of the beamline staff at the Australian Synchrotron, a new dedicated characterization protocol has been developed for scanning the microstructure of individual PAN precursor and carbon fibers. A microstructure map of individual fibers as small as 5 microns in diameter is achieved in a matter of minutes. The SAXS signal helps to understand the pore development in fibers while the WAXS signal helps to identify the critical microstructure parameters for optimizing fiber modulus. Using both signals simultaneously, we can monitor and optimize the mechanical strength and stiffness along each phase of the production process from PAN dope to carbon fiber.”

Pierlot notes that within CarbonSpec, the team is also developing new instruments and test methods. “For example, we are measuring transverse modulus and strength in addition to the normally reported axial properties of the fibers. We think we can use the new method we have developed for this to also measure axial compression strength.” The latter has long been a challenge because the diameter of a single carbon or PAN fiber is very small (5–10 µm), making it difficult to apply a true axial compressive stress without causing buckling.

20% increase in strength, next-generation carbon fibers

“We have improved our understanding of how to convert polymer into fiber and are now making commercial fiber,” says Abbott. “We are applying these technology tools to other precursor polymers to make SIROPAN, which is the CSIRO version of PAN using RAFT. We can make kilograms of that fiber now.”

“The next step is to assess the benefits of using RAFT polymers,” he continues. “We are still making PAN, but we’re better controlling the molecular weight and increasing it while lowering the viscosity, which can produce stronger carbon fiber.” How much stronger? “We’re not sure yet, but our aim is 20% stronger,” says Abbott. “We know that 10% stronger is not enough of an improvement to make changing the precursor financially feasible — 20% is the minimum necessary according to industry.”

- Develop novel precursor polymers via RAFT (high-quality polymers or different properties)

- Develop commercially competitive polymer processes (FLOW)

- Understand the conversion of polymer into fiber (wet spinning) for lower cost and higher properties

- Understand the influence of precursor properties on carbon fiber properties, better predict carbon fiber properties and optimize the process based on these measurements and predictions (CarbonSpec)

- Produce bespoke carbon fibers for specific end applications by engineering the PAN and carbonized fiber

“The carbon fiber industry is growing at 10% every year,” says Abbott. “We’d like to partner with well-established and/or new industry players who are interested in improving carbon fiber quality, performance, cost and sustainability.”

“We’re testing six different precursor formulations and will carbonize these at Carbon Nexus,” adds Skidmore. “We hope to have results by the end of this year. It takes a while to get from the RAFT polymer to a white fiber and then through carbonization.”

Abbott adds, “We want strong results by year end, but we’re in this for the long run.”

This research is supported by the Science and Industry Endowment Fund.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More