Software shortens design path to longboard

Materials information program helps optimize materials selection.

Read MoreAutomated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

WatchThermoplastic composite panels deliver affordable housing solutions

Modular construction concept takes composite housing another step forward, offering a wide range of comparably priced housing solutions to builders of all types.

Read MoreHarbin Hafei Airbus partners with Plataine and Argosy for improved traceability, efficiency and yield

Joint venture composites manufacturing center implements Plataine solution for tracking parts, materials and tools.

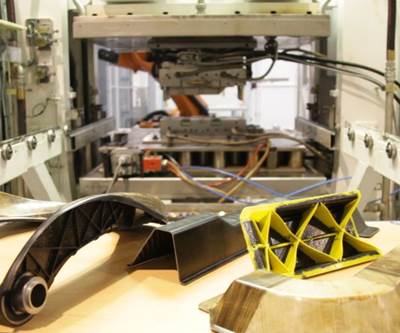

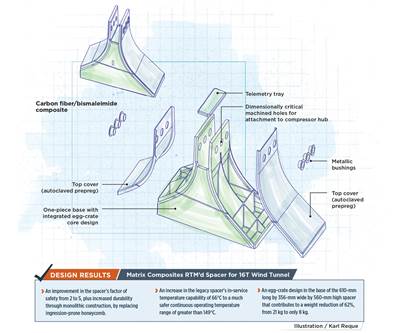

Read MoreRTM-based redesign advances safety for one-of-a-kind wind tunnel

Glass fiber and honeycomb spacers between compressor blades get upgraded to a higher factor of safety with less weight using solid carbon fiber and RTM.

Read MoreArevo composite additive manufacturing: the future of AFP?

Its multi-axis, continuous fiber technology eliminates tooling, matches strength of titanium parts at 1/3 the weight and cuts part cost vs. hand layup/autoclave cure by a factor of 5.

Read MoreStatistical data pooling in design allowables

In the debate about virtual testing’s role in the design allowables process, one common ground is that it can reduce the number of physical tests required in the traditional building block approach (BBA), in the same that way that data pooling is already used.

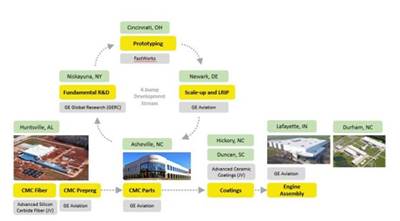

Read MoreVertically integrated CMC supply chain

GE Aviation's new ceramic matrix composite supply chain includes fiber, prepreg and unprecedented parts production facilities, plus a strongly tied 4-bump development stream.

Read MoreGE Aviation's CMC parts facility in Asheville, NC

CW's first-hand look at ceramic matrix composites production.

Read MorePlant Tour: GE Aviation, Asheville, NC, US

An avant-garde approach to unprecedented CMC parts production.

Read MoreAutomated Preforming, Part 2: Glide Forming

Flat layups are shaped into stringers with different cross-sections, lengths, thicknesses and curvatures using a single machine at rates up to 10 mm per second.

WatchPreforming goes industrial: Part 1

ATL and AFP-based preforming options now abound for processing dry and/or impregnated reinforcements as quickly as 1 minute or less with potential yearly part yields in the millions.

Watch