Carbon fiber/epoxy in production boats

Scout Boats and now Hinckley Yachts showcase how demand for lighter, faster performance pushes materials and process change.

WatchAutomated Preforming, Part 6: Coriolis Composites

Pioneer in automated fiber placement (AFP) advances preforms for overmolded thermoplastic composites enabling production of one automotive part every 20 seconds.

WatchContinuous fiber thermoplastics are smart for world’s largest appliance manufacturer

Haier uses Covestro CFRTP in Casarte line of “smart” air conditioners

Read MoreAutomation, automotive, recycling and more from JEC World 2018

Mass production of automotive composites, recycling and composites in shipbuilding are just some of the themes from this year’s JEC.

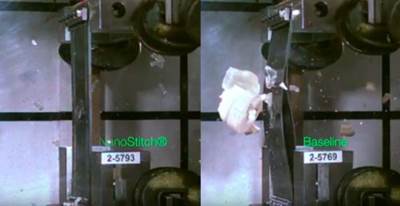

WatchNanoStitch update: 60-inch wide sheet, industrial capacity, dramatic test results

N12 Technologies adds second facility in Boston and capacity at UDRI in Ohio while amassing knowledge to prevent microcracking and delamination in applications from sporting goods to aerospace.

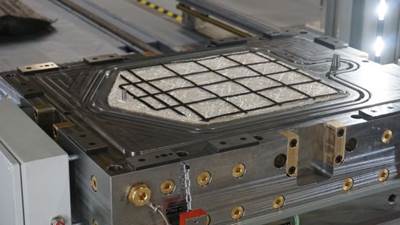

WatchiComposite 4.0 — cutting composites cost by 50%

An intelligent, integrated process using 3D fiber spraying, inline inspections/simulation and embedded RFID chips to cut scrap and rejections for structural HP-RTM epoxy parts.

Read MoreConsolidating thermoplastic composite aerostructures in place, Part 2

Thermoplastic composite structures could eliminate the autoclave and fasteners, but will a one- or two-step process prevail?

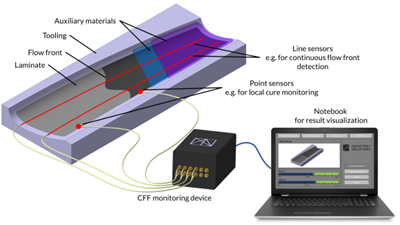

Read MoreSensors for monitoring resin infusion flow front and cure

InFactory Solutions commercializes technology to provide real-time resin impregnation and cure data across composite parts for zero-defect, intelligent process chains.

Read MoreAirborne, Siemens and SABIC partner to mass produce thermoplastic composites

Flexible, automated production lines, featuring radically low conversion costs, aimed at millions of parts/yr — CW’s interview with all three companies.

WatchCarbon Fibre Preforms for low-cost and zero waste

Chopped fiber preforms in seconds, 1200°C burn resistance for hours, low-cost CFRP to replace metals

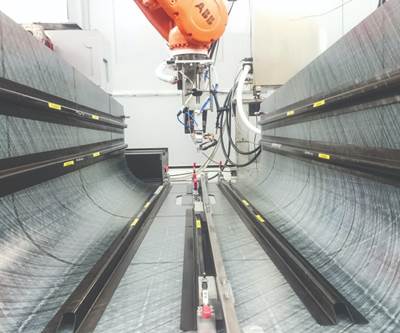

WatchFiber Patch Placement at scale

SAMBA automated cells now offered in Step, Pro and Scale models, for 3D preforming dry fiber and prepreg at rates up to 15-100 kg/hr.

WatchShapeTex preforms successful in automotive parts

Shape Machining Ltd. has demonstrated lightweight composite parts in automotive development program.

Read More