SGL offers high-performance organosheet and thermoplastics for overmolding

“Thermoplastic toolbox” includes LFT, UD tapes, woven semi-finished sheets and carbon/glass hybrids in PA and polyolefins for automotive and other high-volume applications.

Read MoreCFRP bests steel in precision ball joints

Near-zero backlash in bearings and automation components.

Read MoreCarbon-Kevlar Hinge

Besting metal hardware in weight, thickness, 3X load capacity and 1 million fatigue cycles with no degradation.

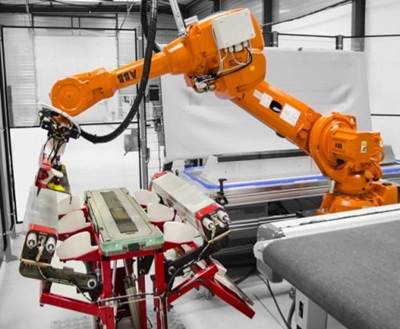

WatchAutomated preforming: Intelligent automation in pick-and-place systems

Layups go industrial with hand-like grippers that can fold fabric or prepreg into corners and robot-mounted cameras that inspect from fabric to cut plies to fiber gaps in final preforms.

Read MorePlant Tour: FiberCore Europe, Rotterdam, The Netherlands

From debond-proof bridges to cost-saving infrastructure rehab, InfraCore technology is establishing composites as the fourth major construction material.

Read MoreFirst all-electric production yacht features carbon fiber construction

Leader in luxury yacht innovation commits to fossil fuel-less future

WatchComposites and metal vie for fuselage and driveshafts in "Racer" next-gen, high-speed rotorcraft

New compound helicopter demonstrator set to fly in 2020 with hybrid fuselage and flexible metal driveshafts for twin pusher turboprops but will trial carbon composite shafts by 2021.

WatchbigHead, Cranfield University discuss Knowledge Transfer Partnership

bigHead Bonding Fasteners and Cranfield University have formed a Knowledge Transfer Partnership (KTP) focused on new joining technologies for composite materials.

Read MoreAutomated Preforming, Part 5: Holistic Quality Optimization

Simulation and testing key to integrated approach for optimization of automated preforming, offering time and cost savings as well as basis for automated quality inspection.

WatchIBEX 2017 show report

Increased attendance and exhibitors despite Irma, continued delivery of latest in composite technologies for marine industry.

WatchReconfigurable tooling: Revolutionizing composites manufacturing

Shape-changing molds eliminate tooling for large 3D panels while automated assembly fixtures go modular, using metrology to reduce cost and shimming.

Read MoreHigh-speed, 3D winding of large, complex-shaped composites

Cygnet Texkimp is translating decades of fiber-handling and processing know-how into machinery that opens new opportunities for composites manufacturing.

Watch