3D knitting solves preforming cost, time

Disruptive digitized technology a dramatic step-change in near-net preform production for Dassault Falcon interior air duct.

Read MoreNew and newer at CAMX 2016

Airbus subsidiary for Industry 4.0 composites plus new products, processes and resources on display.

Read MoreIs the BMW 7 Series the future of autocomposites?

BMW AG's Dingolfing, Germany, auto manufacturing facility is well known for churning out a variety of car models and types, and the 7 Series is among them, famous for its steel/aluminum/composites construction. Does this car represent the optimum of composites use in vehiicles? This plant tour of the Dingolfing plant looks at how composites on the 7 Series come together.

Read MoreFRP charge-air cooler stands up underhood

Injection molded glass/PA streamlines turbocharger intake manifold build.

Read MoreAutomated filament winding aids segmented blade production

Roth Composite Machinery system is part of ENERCON’s optimized production for modular blades.

Read MoreComposites enable portability in driving simulator

FRP design enables portable, light-tight, enclosure with an image-projection-grade inner surface.

Read More20 years of automating composites

Accudyne Systems provides solutions to complex processing challenges, like its recent Small Parts Laminator that picks, places and forms plies in one minute.

Read MoreBMW 7 Series Plant: Dingolfing, Germany

Via four different manufacturing methods, CFRP goes mainstream in automated multi-material BIW and assembly operations at BMW’s busiest plant.

Read MoreFast-build construction with composites

A Brazilian modular wall system that can deliver affordable homes and schools in days is exported to meet global needs, including for refugee resettlement.

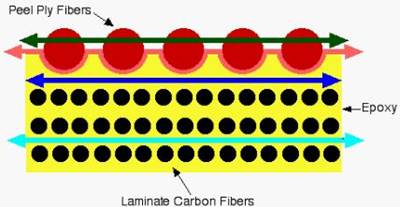

Read MoreWet and dry peel plies

Thinking of using only peel ply as adhesive bonding surface prep? You should understand all of the issues involved.

Read MoreThe resurgence of GLARE

Airbus pursues fiber metal laminates for future narrowbody construction, citing cost, weight, repair and lightning strike benefits.

Read MoreFaster, cheaper nanomaterial safety screening

UCLA develops new test to assess hazardousness of engineered nanomaterials.

Read More