Composites durability and an asymmetrical pandemic

Highly engineered, long-life products, like those made with composites, even if thrown off stride by a recession, have a built-in time horizon that extends beyond the timescale of the pandemic.

Read MoreLight resin transfer molding

Magnum Venus Products introduces its new Fast Flow light resin transfer molding (LRTM) system, which offers reduced injection times, minimal waste, and minimal post-processing.

WatchComposite aerostructures in the emerging urban air mobility market

In the not too distant future, point-to-point, limited-distance, piloted and autonomous air travel for people and cargo will be the norm. Composites will make it possible.

Read MoreIntroducing GreenPoxy bio-based epoxy resin systems

Sicomin Epoxy Systems offers an introduction to GreenPoxy - the company’s line of bio-based epoxies and gelcoats, available in industrial quantities for a wide range of manufacturing processes and market applications.

WatchMold cleaners, primers, sealers and internal/external releases

AXEL Plastics reviews its line of mold cleaners, primers, sealers and internal and external mold releases designed for closed mold and pultrusion manufacturing processes.

WatchPhysical testing to characterize composites

Shimadzu Scientific Instruments reviews use of static tests, impact tests, internal observations and fracture observations to assess and characterize the physical properties of composite parts and structures.

WatchVitrimers: The reprocessable thermoset

Vitrimers are not classic thermosets and they are not classic thermoplastics, but they behave like both and as such offer the best of both worlds. CW catches up with Mallinda for an explanation.

WatchAZL Aachen webinar: Sustainability and recycling

AZL Aachen is hosting the fourth webinar in its Lightweight TechTalk series, titled, “Sustainability and Recycling of Composites,” on Tuesday, Sept. 29, 5:00 am-7:00 am EDT (11:00 am-1:00 pm CET).

Read MoreWomen in the Composites Industry launched

A new organization focused on the promotion of women in composites manufacturing is having a soft launch at CAMX 2020, emphasizing networking, mentorship and education.

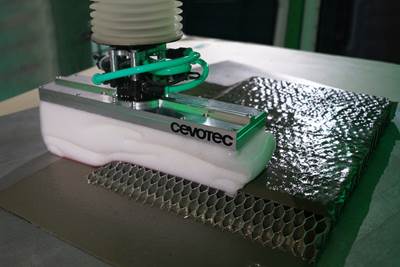

Read MoreNext-generation automation for high-performance composites fabrication

Cevotec’s Fiber Patch Placement technology uses robot-based systems to automate material layup for complex composite parts and structures, saving 20-60% in production time and costs.

WatchBladder and caul solutions for trapped & complex composites fabrication

Smart Tooling reviews the function and application of its shape memory polymer tooling bladder and caul solutions for the efficient and cost-effective manufacture of trapped and complex geometry composite parts and structures.

Watch