Wind foam sources: PET, SAN & PVC

That polyethylene terephthalate (PET) foam is the core material of the future appears to be an open secret within the composites industry.

Read MoreCore for composites: Winds of change

Core materials suppliers lean into the bracing breeze of big-blade challenges raised by the burgeoning wind energy industry.

Read MoreBye-bye black magic

Noting the great pressure to meet quality standards in a variety end-markets, CT editor-in-chief Jeff Sloan sees the composites community making a transition away from the old black magic to scientific process management.

Read MoreNo dark clouds at JEC

Icelandic ash aside, there were no dark clouds over the JEC show floor as the 2010 event proved to be a pleasant surprise.

Read MoreMachining carbon composites: Risky business

As composites take a larger part (and form larger parts) in the aerospace structures sector, it’s not just a make-it-or-break-it proposition.

Read MoreNegating negatives

Composites Technology magazine's editor-in-chief Jeff Sloan says the April issue's cover story on startup electric car makers is proof that there are serious carmakers willing to give composites more than a serious look.

Read MoreTime to leave the recession in the past?

One of the quirks of predicting and assessing the performance of an economic system is that we often don’t know with certainty what’s happening until after the fact.

Read MoreCarbon Fiber: UP!

Despite 2008-2009 recession lows, prognosticators at CompositesWorld's recent Carbon Fiber Conference predict a decade of highs.

Read MoreShifting paradigms

CT editor-in-chief Jeff Sloan contends that now is the time for the North American auto industry to begin rethinking how it designs and builds cars.

Read MoreBio-based fillers: Reducing SMC mass

The Bio-Lite Technical Center of Excellence at the National Composites Center (Dayton, Ohio) is developing sheet molding compound (SMC) recipes capable of yielding finished parts with specific gravity as low as 1.2.

Read MoreSupply and Demand

HPC’s editor-in-chief says its time to answer a perennial question raised at the annual Carbon Fiber Conference: "Has the time come again for the industry to more openly share data about carbon fiber supply and demand?

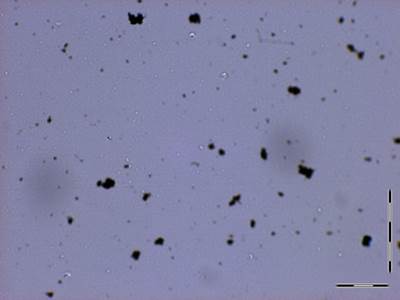

Read MoreThe key to CNTs: Functionalization

An emerging supply base is integrating carbon nanotubes into commercial products that enable composites manufacturers to optimize part performance.

Read More