Composites enable new advances in engine technology

CompositesWorld's conference director Scott Stephenson recalls a presentation at the recent Carbon Fiber 2010 conference (Dec. 7-9, La Jolla, Calif.) by Doug Ward of GE Aviation (Cincinnati, Ohio) on design trends in commercial jet engines that favor the use of composites.

At the recent CompositesWorld Carbon Fiber 2010 conference, held in La Jolla, Calif. (Dec. 7-9, 2010), Doug Ward of GE Aviation (Cincinnati, Ohio) spoke about how composite materials are earning their way onto his company’s GEnx engines — reputedly the most efficient jet engines yet designed — for a variety of aircraft, including the Boeing 787 Dreamliner. Composites are clearly proving themselves in this structurally demanding and important aerospace application.

Airlines are under increasing financial and environmental pressure to operate more efficiently with a smaller carbon footprint. Further, the aircraft operator is increasingly subject to scrutiny by surrounding communities interested in reducing noise during take offs and landings while maintaining safety and reliability standards. GE Aviation stepped up to the plate with its GEnx engine design, which will be produced in two versions for the Boeing 787 and 747-8. GEnx engines burn 15 percent less fuel and emit 85 percent less nitrous oxide (NOx) than the CF6 engines that precede them. Further, they are 30 percent quieter than the CF6. At the same time, says Ward, the GEnx engines require fewer parts — which means savings in maintenance, repair and overhaul (MRO) costs that contribute to a 30 percent reduction in cost of ownership compared to previous engines. The composites-intensive design of the GEnx means the four-engine Boeing 747-8 will have an approximate 1,550-lb (680-kg) weight reduction, equivalent to seven additional paying passengers. The design also saves about 660,000 gallons (2.5 million liters) of jet fuel per year, per aircraft.

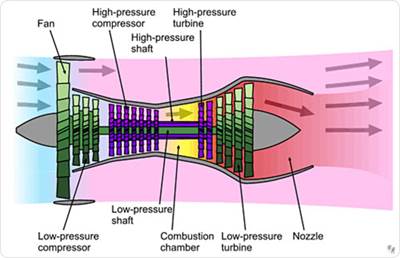

What made these vast improvements in engine performance possible? Ward says, “Engine core sections have become smaller, thanks to better materials and design in the hot section and advances in cooling technology — but that means that fans are becoming larger for better propulsive efficiency.”

During jet engine operation, a portion of the air that passes through the fan inlet is compressed and burned in the combustion core chamber and expelled as a high-velocity exhaust jet. But a greater proportion of the air bypasses the core, pushed rearward by the fan through the bypass fan duct. The bypass fan air generates the majority of thrust for these high-bypass engines. The larger the amount of air that travels through the fan bypass duct compared to the engine core, the higher the bypass ratio. The higher the bypass ratio, the lower the fuel burn rate, plus less noise is generated because the larger bypass airflow helps mask the noise generated by the core’s exhaust. GEnx engines have a bypass ratio of 9.5 — an early 1950s-era jet engine’s bypass ratio was 0.3, for comparison — which means that the fan now constitutes 33 percent of the engine’s weight, reports Ward.

Fan blade weight, it turns out, has become a significant driver of change in propulsion system weight. For example, a 1-lb/0.45-kg increase in fan blade weight requires a corresponding 1-lb increase in containment case weight, a 0.5-lb/0.23-kg increase in rotor weight, and so on, causing weight increases to cascade throughout the engine system. The trend toward larger fans thus drove the need for lighter materials. “Carbon/epoxy materials for fan blades simultaneously reduce fan weight and improve durability as compared to metallic structures,” explains Ward, by offering increased specific stiffness, lower density, better fatigue strength and, most importantly, improved damage and defect tolerance.

GE Aviation started to incorporate composites into its fan blades about a decade ago. But in the GEnx engine, composites have enabled the design of larger blades, with more effective aerodynamics than could be produced with previous materials. Therefore, the fans require fewer blades. In fact, only 18 fan blades are required for the GEnx fan. By comparison, the GE CF6 engine’s fan has 36 blades. This difference provides designers the opportunity for additional weight savings.

Other composites in the GEnx, reports Ward, include the containment case, which is reinforced by carbon fiber braid. The GEnx is the first jet engine to use a composite front fan case. The fiber is Toray (Tokyo, Japan) T700 standard modulus, braided by A&P Technology (Cincinnati, Ohio). The containment case weighs 700 lb/318 kg less per two-engine aircraft than a metal case and requires no hexavalent chromium coating because galvanic and other corrosion concerns are eliminated. Additional compoRead the full story about the GEnx jet engine’s “Composite fan blade containment case,” in the HPC Focus on Design feature lsited under "Editor's Picks," at right). Looking ahead, Ward told conference attendees that GE is assessing ceramic matrix composites for use aft of the fan case to meet the challenge of heat because temperatures range from 1000°F to 2000°F (538°C to 1093°C).

Ward says GE is considering composites in more engine components in the future to gain even greater weight savings. Although composite materials enable higher bypass-ratio turbofans, with outstanding damage tolerance and residual strength, he noted that, as always, material cost is the greatest hurdle preventing further penetration of composites in the aviation engine market.

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

Composite fan blade containment case

Innovative use of carbon-fiber braid yields a ductile structure that resists blade impact.

Read MoreAviation Outlook: Composites in commercial aircraft jet engines

Airlines' need for fuel-efficient flight provides the thrust behind composite lightweighting strategies in jet engine manufacturing.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More