CW Business Index at 49.7 – Industry largely unchanged

Steve Kline, Jr., is the director of market intelligence for Gardner Business Media Inc. (Cincinnati, OH, US), the publisher of CompositesWorld magazine, discusses the Compositesworld Business Index for April 2015.

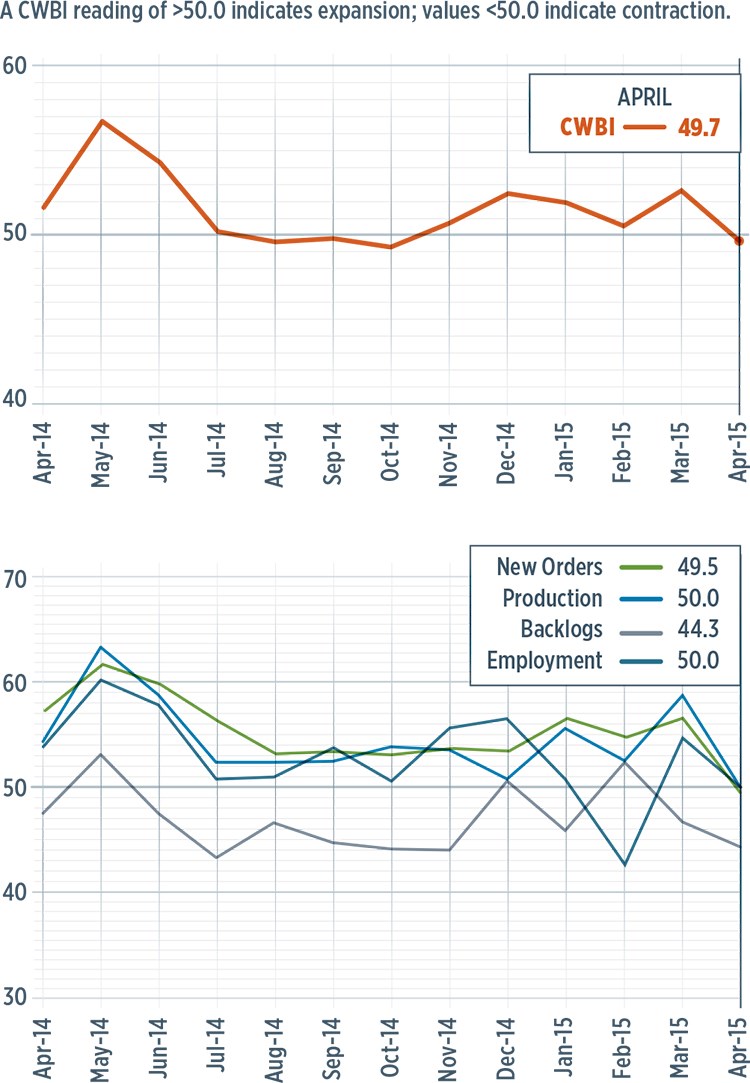

With a reading of 49.7, the CompositesWorld Business Index for April 2015 showed that the U.S. composites industry contracted at a very modest rate in the month of April. Prior to that, the industry had registered either modest growth or been flat since July 2014. This is not all bad, considering the industry had fairly strong growth in the first half of 2014. Compared with one year earlier, the index contracted 4.2% in April. This was the fourth straight month of month-over-month contraction. The industry was still growing on an annual basis, but the rate of growth was very low.

In April, new orders in the US contracted for the first time since November 2013. The subindex fell quite sharply compared to the previous three months. Production was flat in April, the first time it had not expanded since December 2013. Backlogs had contracted every month but one, since May 2014. Compared with one year ago, the backlog subindex had contracted for four straight months. The trend in backlogs indicated that capacity utilization at composite fabricators had seen its peak rate of growth this cycle. However, the rate of contraction in backlogs had started to slow on a month-over-month basis. Employment was unchanged in April. The subindex had been bouncing back and forth between growth and no change since August 2014. Exports continued to contract due to the relatively strong dollar. However, the export subindex had improved since reaching a low point in September 2014. Supplier deliveries lengthened at their fastest rate since April 2012.

US material prices increased at their fastest rate in April since November 2014. However, the rate of increase was still relatively low. Prices received increased for the fifth straight month. The rate of increase in prices received generally had accelerated during the five previous months. Future business expectations improved in April. Since August 2014, they have been on a significant upward trend. In fact, expectations were noticeably above their historical average.

In April, US composite manufacturing plants with 100-249 employees had expanded every month since June 2014. In four of the previous five months, the subindex for this subgroup of plants had been above 63.0. However, in April, all other plant sizes contracted. Facilities with more than 250 employees contracted at their fastest rate since the Index was first recorded in December 2011. Companies with 20-99 employees contracted in April after expanding in March. Companies with 1-19 employees contracted for the second month in a row. In fact, these companies had, in April, contracted every month but one since June 2014.

Regionally in the US, the West was the only one to see any significant growth in April. It had grown every month but one since August 2013. The North Central – East region also expanded in April, but the rate of growth was quite slow. Both the North Central – West and the Northeast contracted after growing in March. The decline in the Northeast was particularly sharp. The Southeast was flat.

In April, it was evident that future capital spending plans had been hit quite hard in recent months. The previous two months had seen spending plans contract more than 40% compared with the same period, one year earlier. And, spending plans also had contracted four of the preceding five months. On an annual basis, spending plans had contracted for five consecutive months.

Read Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreModeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read MoreVIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read More

.JPG;width=70;height=70;mode=crop)