Recycled carbon fiber: Its time has come

Impressive industry growth puts a new emphasis on the role of carbon fiber recycling.

The carbon fiber industry has changed a lot in the past 15 years. In 2000, the global market for carbon fiber was less than 20,000 MT. Now, it is greater than 60,000 MT per year, and forecasts indicate this will increase to between 100,000-140,000 MT, annually, in the early 2020s. The impressive growth that we’ve seen already — and that we expect to continue — puts a new emphasis on the role of carbon fiber recycling in the development of the industry.

The process from manufacturing carbon fiber to production of finished components is wasteful; it is estimated that more than 30% of produced carbon fiber ends up as waste at some point in the process. Where the carbon fiber composites industry most differs from other industries that produce high proportions of waste is that it lacks an effective recycling solution. This is not to say that we cannot recycle carbon fiber. ELG Carbon Fibre is one of several companies that have developed cost-effective means of recovering carbon fibers from manufacturing waste and end-of-life components without significantly degrading fiber properties. But there are significant barriers to returning reclaimed fiber materials to the market.

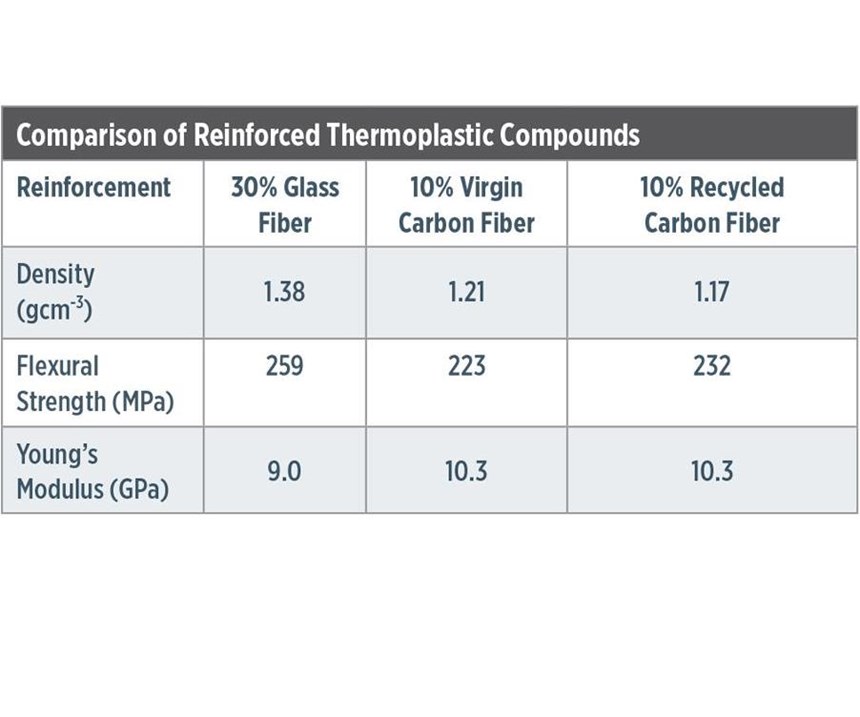

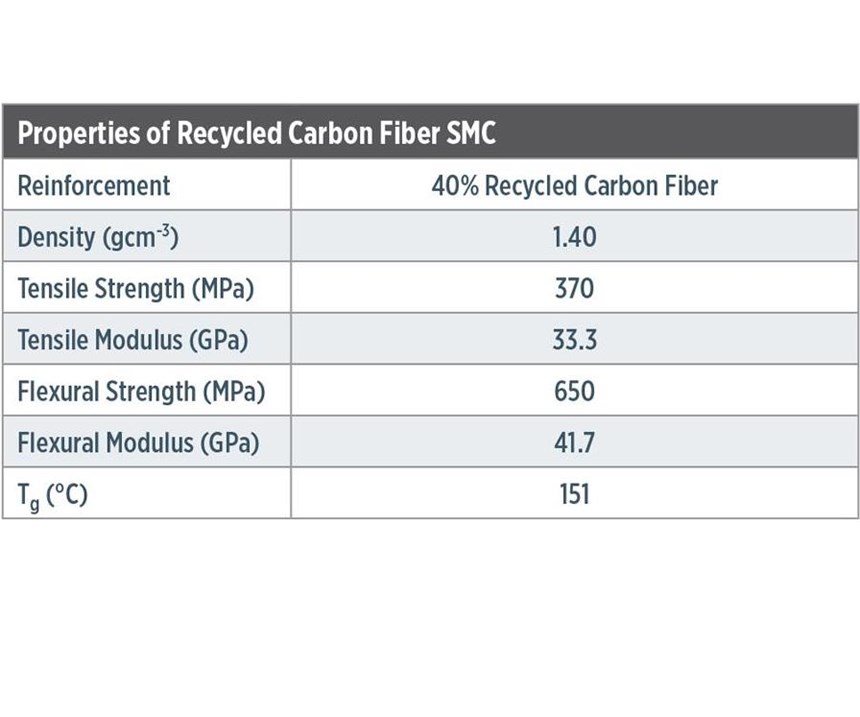

To understand why, we need to briefly recap the current status of recycled carbon fiber materials. Today, recycled products exist in forms that are suitable for use by compounders (milled and chopped fibers in powder or pellet form) and in composite layups (nonwoven mats as dry fabrics as well as prepregs and SMC materials), as shown here in Tables 1 and 2. However, the use of these products outside of R&D projects is, thus far, very limited.

The major barrier that must be overcome is one faced by all new materials — lack of knowledge about mechanical properties and processing characteristics, and lack of large-scale demonstrators that prove the economic, technical and environmental justification for using these materials. Although there are a number of projects that are addressing these issues, the push from the manufacturing side of the supply chain to find a solution to its carbon fiber waste problem generally isn’t matched by a pull from the supply chain’s design side to find ways of using recycled carbon fiber products.

To date, the most successful demonstration of recycling has been BMW’s (Munich, Germany) use of reclaimed carbon fiber materials in its i3 and 7-Series models, in which manufacturing waste from dry fiber processes has been converted into new product forms and used in closed-loop recycling solutions. This was greatly facilitated by the integrated supply chain that BMW and SGL Group (Wiesbaden, Germany) established. If such integrated supply chains don’t become the norm in future, then it is vital that all elements of a supply chain work closely together not only to develop methods of recycling carbon fiber, but also to get recycled carbon fiber products back into the supply chain.

Why should we do this? From an economic standpoint, recycled carbon fiber products can reduce the cost of lightweighting, used either on their own or in conjunction with virgin carbon fibers. In fact, making lightweighting strategies affordable must be a primary goal if we are to see increasing use of carbon fiber in high-volume applications. If we address this challenge, then we can increase the total use of carbon fiber in these developing markets. From the environmental standpoint, reducing waste and reusing materials that have a high embedded energy, and which can be recycled in an energy-efficient manner, is the right thing to do, from a social responsibility point of view. It also is a legislative requirement in some countries.

Finally, there’s the question of the growth forecasts for carbon fiber. It has taken the industry 15 years to add 40,000 MT of carbon fiber manufacturing capacity. If the demand forecasts are to be believed, the next 40,000 MT of capacity must be added in the next 5 years. Making use of high-cost materials that, today, are consigned to landfill can be part of the solution to filling the anticipated gap between supply and demand.

In summary, a number of companies across the globe have developed cost-effective solutions to carbon fiber recycling, and an initial range of products now available for the compounding and composites industries. The time is right for the industry to work together, to move recycling from the fringes to its rightful place as an integral part of the carbon fiber market. In doing so, we improve the cost and the environmental footprint of our businesses, create additional and sustainable supply chains for critical raw materials, and help the overall carbon fiber composites industry grow.

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Recycled carbon fiber update: Closing the CFRP lifecycle loop

Commercial production of recycled carbon fiber currently outpaces applications for it, but materials characterization and new technology demonstrations promise to close the gap.

Read MoreRecycled carbon fiber proves its potential for aircraft interiors

An Airbus-led team characterizes RCF veils and shows their ability to best glass fiber composite sidewalls in cost, weight and surface finish.

Read More