Composite rotary milking platform evolves via process innovations

Infusion and LRTM-based processes and design enabled Waikato Milking Systems to bring a lighter, less labor-intensive platform to the global dairy market.

Share

Developing a lightweight, modular composite milking platform. Waikato Milking Systems switched to a composite rotary platform design in 2007 to solve durability, transport and assembly challenges with traditional concrete platforms. In the years since, evolving needs have led to numerous design and process innovations. Photo Credit: Waikato

Operating for more than 50 years, Waikato Milking Systems (Hamilton, New Zealand) provides technology solutions for dairy farms around the world. Among its products, the company supplies the platforms, automation, milking and milk cooling equipment, and storage tanks needed to run a productive and cost-effective in-line or rotary-style dairy operation.

Rotary milking platforms are flat, circular structures that accommodate from 50 to more than 100 cows standing in gated milking stalls. The platform sits atop a roller-based undercarriage and equipment that powers a relatively slow-paced 360-degree rotation, passing one or two stationary human operators managing the milking equipment for each cow as it passes. The rotary system allows for an efficient milking process with minimal personnel.

Meeting challenging requirements. For each iteration of the Centrus platform design, core requirements included manufacturability, scalability and light weight to support the cows and people using the platform and to help sustain the undercarriage equipment beneath the platform. Photo Credit: MVP

Traditionally, Waikato’s rotary platforms are made from concrete, but according to David Morris, country manager for Waikato, these platforms can weigh up to 100 tons, putting a lot of stress on the undercarriage and support equipment beneath the platform. A concrete platform also has to be poured on site, making the manufacturing conditions difficult to control and the product impossible to transport to global customers.

In 2007, Waikato began searching for a way to build a lighter-weight platform to increase the durability and lifespan of its rotary platform equipment. Through industrial production solutions specialist Magnum Venus Products (MVP, Knoxville, Tenn., U.S.), Waikato was introduced to fiberglass composite materials — which, Morris says, cut the weight of the concrete platform by 75% and enabled Waikato to switch to higher quality, factory-produced modular components that could be easily transported to customers around the world.

Waikato’s composite rotary platform product, now named Centrus, has developed in a multi-step process over the past 15 years, Morris explains. “There have been four generations, as we call them,” he says, each requiring technology innovation and evolving through various manufacturing processes, including vacuum bag infusion, light resin transfer molding (LRTM) and reusable silicone bag infusion.

First prototypes: Vacuum bag infusion

Charles Tur, closed mold product manager at MVP, explains that simple hand layup was quickly ruled out as a process option for the platforms — a more cost-effective, less labor-intensive process would be needed.

To make the first two prototypes for testing, Waikato used vacuum bag-assisted infusion (Fig. 1). The platform was constructed from E-glass/vinyl ester with layers of Kevlar and PET foam core where needed.

Waikato chose, for its first composite prototypes, the company’s relatively small, nine-piece, 14-meter-diameter platform. Technicians loaded cut glass and Kevlar fabric onto the female mold, followed by pre-cut PET foam core and metallic components (to connect the platform to the undercarriage). Vacuum bags were attached and the structure was infused with vinyl ester under vacuum.

According to Tur, one challenge with this process was that the raised metallic and foam inserts introduced resin flow issues during infusion. “So we had to optimize,” he says. MVP outfitted the setup with a pneumatic-based infusion machine to control the resin flow pressure. In addition, a reusable silicone resin channel was designed to house a single injection port on the top of the part. Resin was then directed to specific areas of the part via designated channels underneath the vacuum bag.

Vacuum bag infusion, Tur says, was used for the first trial runs of the platform because it was the easiest process for a company new to composites to perform, and it worked well to build the original full-scale prototypes for testing.

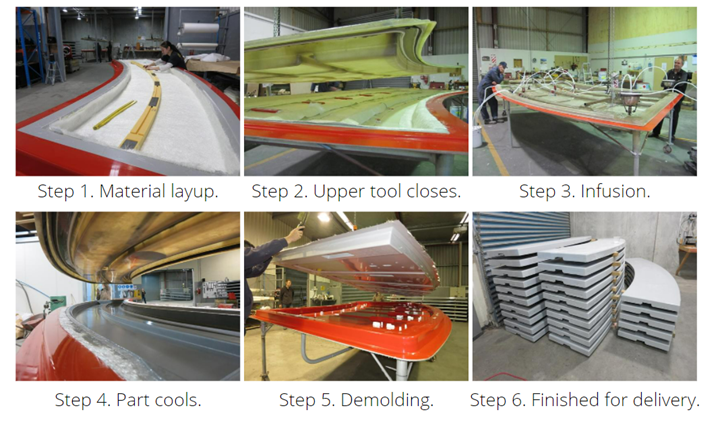

Fig. 1. Vacuum bag infusion. For initial prototype development, Waikato employed a vacuum bag-assisted infusion process optimized by MVP. Photo Credit: MVP

First production platforms (Gen. 1): LRTM

As Waikato began to increase production, though, it became clear that a faster production process was needed. The original infused platform took about 20 hours to produce each section; Waikato was able to reduce the cycle time to five hours per part by switching to LRTM, a closed molding process, for faster resin infusion and part cure.

In an LRTM process (Fig. 2), layers of Kevlar, E-glass fabric, pre-cut foam core, metallic components and additional E-glass fabric are loaded into the lower mold by Waikato technicians. In this design, resin channels are pre-cut directly into the foam core, replacing the silicone resin channels that were used in the original process. This way, the resin could be injected directly into and through the foam, and then through the glass fiber.

The upper mold is lowered onto the lower mold with the help of a crane system and sealed via vacuum. After mold close, vinyl ester resin is injected directly into the foam resin channels under heat and pressure. The final part is demolded via a pulley system, then coated in a gel coat with molded grip tread and pigmented resin for customer delivery.

Using this process, Waikato brought its first commercial products to market in New Zealand in 2008. According to Josh Janmaat, who at that time was technical/design manager at Waikato, the first-generation commercial Centrus platform was a 54-stall platform, made up of nine infused sections of six stalls each and a total diameter of 15.4 meters (50.5 feet).

Fig. 2. LRTM. To bring its first Centrus platforms to market quickly, Waikato opted for closed molding. Photo Credit: MVP

Evolving to larger platforms (Gen. 2): LRTM to Flex Molding

After initial success with the Centrus platform in New Zealand, Waikato decided to expand into the global market. To accommodate U.S. needs for larger platforms, the company developed the Gen. 2 design, which features an 84-stall, 26.4-meter (86.6-foot) diameter platform. Like the Gen. 1 platform, each panel in the Gen. 2 design originally included six molded-in stalls per section, with five- and four-stall versions added later to smaller configurations.

Larger LRTM molds were developed for the larger platform, and, Tur notes, one challenge that arose was that the raised metal and foam core components made it difficult to close and clamp the molds using only vacuum. To solve this challenge, MVP developed a vertical flange that works as a second wing seal on the top mold, hooking onto the bottom mold and suctioning the two molds together when vacuum is pulled.

After the new, larger platform was brought to market, a smaller, 40-stall Centrus product was added to the product lineup. Morris notes that as Waikato continued evolving the product and developing new sizes to fit market needs, new LRTM tooling had to be developed and purchased for each iteration.

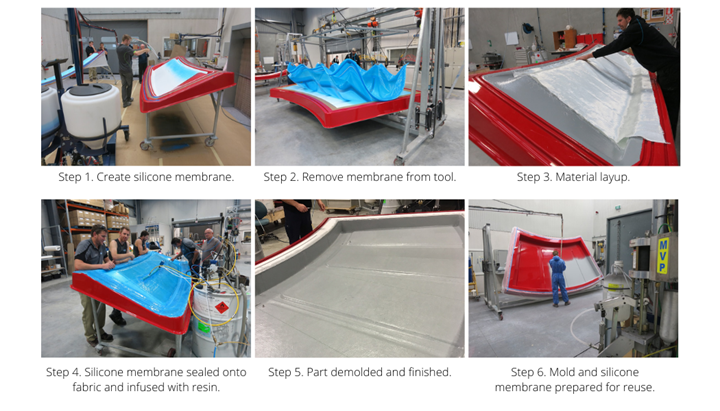

To save on tooling costs and accommodate design and size changes, in 2016 Waikato switched to a process that MVP calls Flex Molding — essentially a liquid infusion process using a reusable, custom-made silicone membrane as an upper mold (Fig. 3). An MVP silicone machine is used to spray liquid silicone onto the mold, which hardens into a flexible upper mold. Then, the E-glass fabric and foam core are loaded onto the bottom mold, the silicone membrane is applied using a special flange to ensure proper sealing, followed by resin infusion and demolding.

Fig. 3. Flex Molding. As Waikato began to add size options and optimize its platform design, a silicone bag infusion process was chosen to save on tooling costs. Generations 2, 3 and 4 now employ Flex Molding. Photo Credit: MVP and Waikato

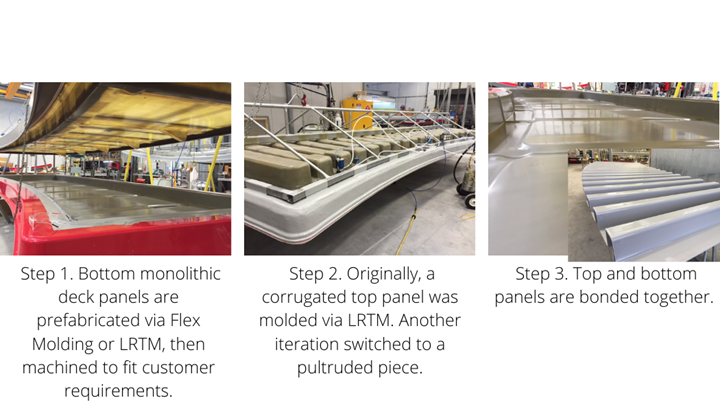

Reducing production costs (Gen. 3): Two-piece bonded design

Eventually, to further reduce costs and labor, Waikato decided, for the Gen. 3 model, to change the overall platform design to a two-part design: a flat monolithic deck panel (the platform on which people or cows stand), and a bottom, corrugated rib structure (on which the undercarriage and other equipment are attached), bonded together. This rib structure was originally molded via LRTM, and the flat deck panel was built in the Waikato factory using Flex Molding. These are bonded with the aid of an MVP adhesive dispensing system (Fig. 4).

According to Janmaat, this design was the first to consist of a single bale section — meaning that rather than manufacture to-order Centrus products using the specific mold sizes that had been purchased, Waikato could now manufacture standardized panels all of one size that could then be CNC machined to fit the size requirements of the customer. Starting with the Gen. 3 platform and continuing to the present, each stall is built individually as a rectangular panel and then machined to fit the curvature and size needed, as opposed to the previous generations that featured molded-in, six-stall sections that were not easily changed. Using this system, he says Waikato could produce up to 16 standard panels per eight-hour shift.

The complex-shaped corrugated structure was a challenge to infuse, Tur says, but MVP developed a strategy with two vacuum points along one side of the part and leave-in resin channels along the corrugated parts — the channels could be molded in, he says, because the part would not be visible after assembly. To simplify this process, Waikato began purchasing ready-to-use pultruded parts from Fibre Composites Australia (Wingfield).

Fig. 4. Two-part design. In Waikato’s third generation, the platform was produced via two parts: A monolithic deck that could be machined to order, and a corrugated upper panel. Photo Credit: MVP

High-volume production (Gen. 4): Flex Molding and CNC machining

As the Centrus product — and milking technology — has advanced over the past several years, demand has increased for larger platforms, Morris says. While the original platforms were designed to accommodate 50 cows, today’s Centrus platforms need to be more than 30 meters in diameter, and able to hold the weight of 110 cows plus the weight of the milking equipment, or approximately 96.8 metric tonnes total.

Waikato’s current generation design involves Flex Molding flat panels, similarly to the deck panels from Gen. 3, but without the pultruded attachment. Shape is added to the panels via foam core sandwiched between E-glass layers, then CNC machined to final size.

“From a technical point of view, generation three was higher-level,” Morris says. “But it became too expensive to make new molds every time we wanted to make a different sized rotary, and it could take months to produce a finished product. We’ve gone back to a very basic process, but we’re now also using the latest technology.”

Morris says that prefabricating up to 200 identical panels per month allows them to be stored and then quickly machined to order. Recently, manufacturing and machining of these panels has been contracted to Janmor Technology (Morrinsville, New Zealand), a local manufacturing consultancy and distributor for MVP, and for which Josh Janmaat, formerly of Waikato and one of the main innovators on this project, now serves as director.

Most recently, Waikato moved manufacturing operations of its Centrus platforms to Janmor Technology. Panels are prefabricated via Flex Molding and machined to size before assembly. Photo Credit: MVP

Today, Centrus platforms are shipped and sold around the world, including to customers in Australia, the U.S., Europe, China and South America. The product is “about 10% more expensive [compared to concrete], but well-received in the market because you can very easily point out the advantages,” Morris says. “The weight savings is the same effect you get with a [composites-intensive] airplane — lower structural weight means less fuel needed to power the aircraft. [These platforms are] very energy-efficient, and that’s very well-received in the world today. Everyone is very conscious of consumption of energy.” In addition to weight savings, Morris adds that, compared to concrete, the composite platforms are more durable — extending the life of the platform from 20 years to 35 — and extend the lifetime of the mechanical equipment, operate at a lower cost due to the low weight, are non-pervious (protecting against bacteria, etc.) and enable greater production continuity and quality control, as they’re manufactured in a factory setting versus poured on the farm site.

According to Morris, some of the technology and innovations used throughout this process of developing Centrus have been carried over for other applications, both by Janmor and MVP customers globally. “We had great support from Charles [Tur] and innovation from Josh [Janmaat], we did some really cool development work and that has carried over into other development areas as well.”

Related Content

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More.jpg;width=70;height=70;mode=crop)