Utilizing proper tooling in each closed mold method is essential to producing a part correctly. Remember to always “Design for the Process.” Use tooling designed for the specific process you are trying to use.

Tooling costs and complexity increase as the part performance requirements and the number of parts to be produced increase.

Tooling requirements vary for each closed mold process:

-

With Vacuum Infusion, standard composite tooling can generally be used, as long as it will hold a vacuum and the flange is wide enough to seal the bag; therefore, tooling costs are lower than those of other closed mold processes.

-

Existing molds can easily be converted for Reusable Bag Molding, and no consumables are used, so tooling costs for this process are relatively low.

-

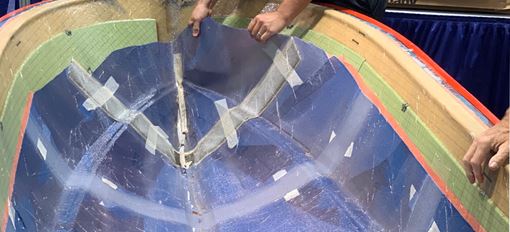

In the Light RTM process, both an “A” side mold and “B” mold are utilized, and they must be high-quality, accurate molds, which accounts for higher start-up costs than with VIP or Reusable Bag Molding.

Find links to more information about tooling on our resources page.