Vectorply and Chomarat Group are two leading suppliers of composites reinforcement products. Vectorply makes more than 500 different styles of reinforcement fabrics for an unlimited number of composite applications. The Chomarat Group offers a wide range of high performace fibers ideal for closed molding applications. The resources below provide insight into a variety of composites reinforcement applications.

Composites Reinforcement

Sponsored Content

Vectorply

About Vectorply

Vectorply is a world leader in the development, manufacturing and distribution of composite reinforcement fabrics engineered to optimize the stiffness, strength, weight and cost of customer-specific applications.

Thermoply™ Commingled E-Glass / Polypropylene Woven & Stitch-Bonded Biaxial

Continuous reinforcement fiber thermoplastic composites offer many desirable attributes including specific high strength & modulus, damage tolerance, recyclability, and potential for high volume production.

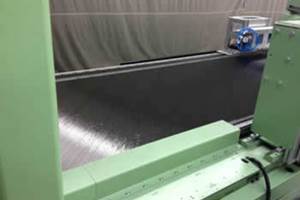

Vectorply Corporation Introduces Heaviest VectorUltra Product

Vectorply Corporation is pleased to introduce the latest product addition to the VectorUltra line of advanced composite reinforcements. The 94 oz/yd² carbon quadraxial fabric, named C-4QX 9400, is an all-standard modulus carbon fiber quasi-isotropic reinforcement fabric that is excellent fit for tooling, panel, and thick section advanced composite applications.

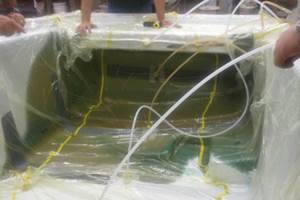

Case History: Scout’s 420 LXF made possible with Vectorply’s Road to Optimization

With a list of must-meet goals in hand, Scout Boats, Inc. turned to Vectorply to assist with laminate design and technical recommendations as they tackled their first epoxy-infused boat hull.

Increasing Shear and Torsional Properties with Carbon Fiber Double Bias Fabrics

While stitch-bonded carbon fabrics are used successfully as direct replacements for traditional 0°/90° woven versions, this article will concentrate on their use in increasing in-plane off-axis (in this case ±45°) laminate properties.

VectorFusion™ Reinforcements Utilized with CCP Composites’ OptiPLUS® Resin for Infused Tooling Applications

With recent advances in CCP Composites’ OptiPLUS® infusion grade, low viscosity, shrink-controlled polyester resin, and the proper selection of Vectorply reinforcements, mold building can be greatly reduced from weeks to only a day or two.

Infusion success starts with “R2O”

Vectorply’s “Road to Optimization” crucial in Cruisers Yachts 390 Express Coupe infusion

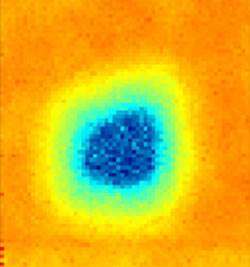

Impact Delamination Reduction of Multiaxial Carbon Fiber Composites Using Interleaved “Micromesh™” Polyamide Veils

Learn about how excessive damage due to impact events can severely limit the use of carbon fiber composites in high performance applications.

Chomarat

About Chomarat

A pioneering developer of reinforcements for closed mold processes, Chomarat is known for its flagship brands such as Rovicore™, Roviflow™ and Aramat™. A keen innovator, the group has invested in carbon technologies through its C-WEAVE and C-PLY™ ranges for direct processes.

C-WEAVE™ High Performance Carbon Fabric from the Chomarat Group

C-WEAVE is a bi-directional (0°/90°) warp and weft woven carbon fabric.

C-PLY™ – a Design & Manufacturing Game Changer

C-PLY is a leading edge carbon NCF reinforcement with structural design benefits, premium surface quality and overall parts cost savings.

ROVICORE™ – the leading Closed Mold Solution

ROVICORE is a reinforcement made with a synthetic non-woven core and chopped glass fibers mechanically stitched together.