Composites One and its partners through the Closed Mold Alliance are the industry’s leading closed mold process experts. We have developed a road map that will help you convert your facility into a successful closed molding operation.

Composites One and its partners through the Closed Mold Alliance are the industry’s leading closed mold process experts. We have developed a road map that will help you convert your facility into a successful closed molding operation.

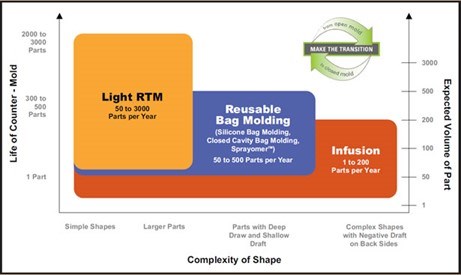

Ensure sure that your company’s executives and operations managers are supportive of closed mold efforts. After your facility has management buy-in, you should evaluate your shop’s production to determine which closed mold process or processes are best for your needs. One way to do that is through this helpful guide. It compares each process using part volume, length of counter mold life and part complexity.

After you have decided which process (and it may be more than one) is right for your business, Composites One and the Closed Mold Alliance offer a variety of training courses that can educate you and your team so the right steps can be taken toward closed mold conversion.

Even after you have learned the basics of these processes, training and evaluation should remain an important part of your production cycle. This will guarantee that you are running the most optimal closed mold shop.

Converting to closed molding will also involve a decision about tooling. Depending on which process is chosen, there is a chance that it will require an investment in new tooling.

This could be as simple as a silicone bag or a complete set of a mold and counter mold. Composites One and the Closed Mold Alliance can help you understand your tooling needs. We can provide access to training that can provide instruction on building tooling in house. In addition, we are aligned with the experts who can work with an individual manufacturer producing professional, high-quality tooling for individual needs.

Once a process has been chosen and tooling is in place, it is time to produce parts using closed molding. It is at this time that Composites One and the Closed Mold Alliance can help evaluate facility infrastructure working to optimize the working environment. Our follow-up training will help keep you on the right path as you experience your closed mold journey.

The Closed Mold Alliance is dedicated to providing you with a complete closed mold solution for your manufacturing needs. Together, the Alliance partners offer education and training, as well as consultation to assist in the conversion to closed mold processes.

Have a question about any of the closed mold processes? Ask a member of our technical support team! You’ll hear back within 48 hours.

Composites Tech Talks brings together the latest in product and process technology to manufacturers and students alike. Learn more about this live webinar series on Composite One's LinkedIn page.