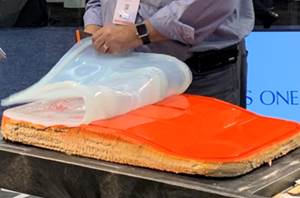

The Vacuum Infusion Process, or VIP, is one of many closed mold processes. It distinguishes itself as the only process that utilizes solely atmospheric pressure to push the resin into the mold cavity. The mold cavity can be a one-sided mold with bagging film being utilized for the “B” side, a two-sided mold, or even a soft “envelope” bag. The process is highly controllable because it is governed by the principles of D’Arcy’s Law. This means there are only three variables affecting the flow of the resin:

- Permeability of the laminate

- Viscosity of the resin

- Pressure differential in the cavity in relation to atmospheric pressure

If all three of these variables are unchanged, then the infusion process will consistently flow the same way with every injection for a given part. This also equates to a very accurate bill of material for a given part since the resin and fiberglass usage will not change.