Toray obtains ISCC certification for European carbon fiber production facilities

Toray Carbon Fibers Europe will product and supply carbon fibers derived from biomass and recycled materials, with future plans to obtain ISCC Plus certification for Japan and U.S. plants by 2024.

Share

Photo Credit: Toray Industries

Toray Industries Inc. (Tokyo, Japan) has announced that its French subsidiary, Toray Carbon Fibers Europe S.A., has obtained ISCC Plus certification for its Lacq and Abidos production plants in South West France. This certification enables Toray Carbon Fibers Europe to allocate and use biomass or recycled materials through the mass balance approach (see more on this below) to produce and supply carbon fiber. Thus, the subsidiary now has the ability to reduce the lifecycle inventory (LCI) of its carbon fiber, prepreg and other offerings and help its customers to enhance product lifecycle assessments (LCA) while contributing to building a circular economy.

The ISCC Plus International Sustainability & Carbon Certification (ISCC), a voluntary certification program, guarantees that the raw materials used are sourced from biomass or recycled materials. It also ensures that there is complete traceability at all stages of the manufacturing process of a product. The mass balance approach tracks the amount and sustainability characteristics of circular and bio-based materials used in the value chain and it is based on verifiable record. This project is open to several sectors such as the food, feed, chemicals, plastics, packaging and textile industries.

Toray Carbon Fibers Europe will start manufacturing carbon fiber derived from biomass and recycled raw materials by the end of 2023. In addition, Toray’s Ehime Plant in Japan aims to obtain ISCC Plus certification by March 2024 and begin producing fiber by close of that year. In the U.S., Toray Composite Materials America Inc.’s carbon fiber facility in Decatur, Alabama, also plans to obtain this certification in 2024. With these three locations obtaining certification, the Toray Group intends to manufacture carbon fiber using biomass or recycled raw materials at plants in Japan, the U.S. and Europe, ensuring stable supplies to customers around the globe.

Toray has already received requests from customers similarly committed to carbon neutrality. From the end of 2023, Toray will offer this carbon fiber for industrial applications such as automobiles and handheld devices where demand for materials to create sustainable products is particularly high. At a later date, other applications, such as aviation and sports, will also be targeted.

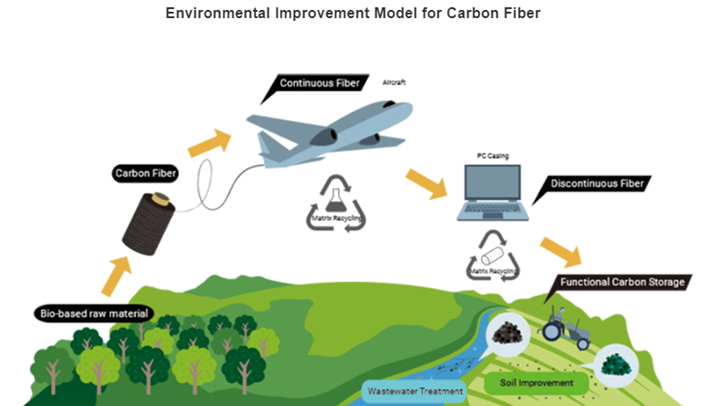

This effort aligns with the Toray Group’s carbon fiber composites business roadmap to achieve carbon neutrality by 2050. Under Project AP-G 2025, its medium-term management program, Toray is actively contributing to the development of a more sustainable economy by quantifying the LCA improvements of customer products, reducing the LCIs of carbon fiber, prepreg and other offerings, and using and recycling bio-based materials as part of its new materials ecosystem.

Toray aims to build a new materials ecosystem that harnesses natural raw materials and returns them to nature in an eco-friendly state. For carbon fiber, the ecosystem will be built using biomass and recycled raw materials to manufacture carbon fiber. This fiber will be made into a composite material and, finally, an end product. At the end of the product’s lifecycle, continuous carbon fiber will be repurposed for the use as discontinuous fiber in other products. The last stage of the carbon fiber’s lifecycle will be its recycling for water treatment or soil improvement.

For related information, read about Toray Carbon Fibers Europe’s recent announcement about its increased annual production of carbon fiber tows and how Toray’s Tenax carbon fiber and PAN precursor have also gained ISCC Plus certification.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

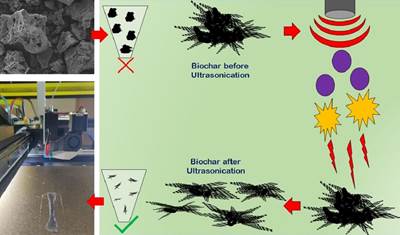

New research developments identify new methods for bio-derived carbon filler reinforcement for biocomposites

Sustainable methodologies employed by researchers from Tuskegee University enable the synthesis of carbon from biomass-based precursor materials, and its effective reinforcement in composites.

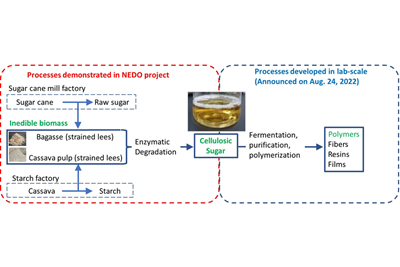

Read MoreToray to develop sugar from biomass waste for production of resins, fibers

The project aims to use waste from sugarcane agriculture for the production of new bio-based materials.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read More