CompositesWorld News

Composite truck component carrier from Lanxess wins GKV/TecPart Innovation Award

Injection-molded glass fiber-reinforced PA6 component is jointly developed with system supplier and truck manufacturer for 35% less weight, replaces DLFT-based design.

Read MoreToray, Specialty Materials strengthen partnership for next-gen aerospace applications

Commercial partnership enables novel solution innovations with domestically produced, high-quality products within the U.S. supply chain.

Read MoreTNO research offers circularity solution for discarded wind turbine blades

Thermochemical method involving pyrolysis extracts fibers, which can then be reprocessed as thermoplastic composites for various recyclable products.

Read MoreNew report reveals U.S. saw 60% growth for offshore wind targets

Business Network for Offshore Wind’s inaugural quarterly report details market trends, supply chain and technology advancements.

Read MoreCannon Tipos, Coriolis Composites mold complex automotive structural part from single preform

Dosing equipment for precise injection and mold engineering enable near-net-shape dry preform for HP-RTM CFRP composite part with rapid cycle time.

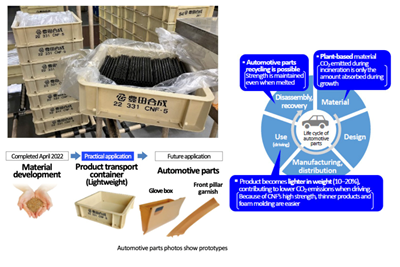

Read MoreToyoda Gosei develops nanocellulose fiber-reinforced plastics for automotive parts

Newly developed CNF-reinforced plastic used in product transport containers combines 20% CNF in a general-purpose polypropylene, aims to reduce CO2 over the lifecycle of components.

Read MoreScott Bader expands partnership with composites supplier Hans Claussen in Scandinavia

Partnership extension continues to grow Scott Bader’s presence in Norway, Scandinavia, enhances composite and adhesive offerings for customers.

Read MoreEuropean hydrogen orders announced by Hexagon Purus

Hexagon Purus is to deliver hydrogen distribution systems and mobile refueling stations for transportation and industrial applications by 2023.

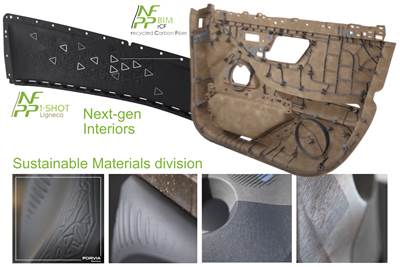

Read MoreFaurecia advances biocomposites, recyclability, reduced CO2 and sustainability in automotive

Efforts include advancing NAFILean materials family in weight reduction and sustainability, as well as new Sustainable Materials division and R&D Center.

WatchAlef Aeronautics launches eVTOL flying car

The all-electric composite Alef Model A has a 200-mile driving range, a 110-mile flight range and fits within existing urban infrastructure for driving and parking.

Read More