Faurecia advances biocomposites, recyclability, reduced CO2 and sustainability in automotive

Efforts include advancing NAFILean materials family in weight reduction and sustainability, as well as new Sustainable Materials division and R&D Center.

Share

Read Next

Faurecia (Nanterre, France), part of the Forvia Group, is a global automotive supplier with a mission to develop technologies for safe, sustainable, advanced and customized mobility. While CW has more recently reported on the company’s carbon fiber-reinforced polymer (CFRP) hydrogen storage tank developments for light commercial vehicles (supplying companies like Group Renault, Stellantis, Hyundai Motor Co. and others), Faurecia’s work also extends into advancing biocomposites and smart materials for sustainable vehicle interiors, an area in which it cites decades of experience.

Faurecia is advancing sustainability within its four business groups: Seating, Interiors, Clean Mobility and Electronics. Across these divisions, the company aims to reduce the CO2 footprint of the materials it uses by 87% by 2030, developing them based on three pillars: use less, incorporate recyclable and recycled materials and create alternatives to petrol solutions, with no impact on cost.

In July 2021, the company created a new cross-functional division, Sustainable Materials, to further develop and manufacture cutting-edge sustainable and smart materials and fulfill these sustainability objectives. Leveraging ultra-low, negative CO2 emission materials, as well as materials integrating thermal, acoustic and biomedical technologies found under the Interiors and Seating Groups portfolios, the Sustainable Materials division seeks to work across Forvia Faurecia’s business groups to propose a low-CO2 cockpit and CO2-negative materials to OEMs.

Photo Credit: slide 12, Faurecia 1H 2022 presentation

Following these advancements, Faurecia has announced plans to build a dedicated Sustainable Materials R&D Center and a pilot plant, both to be operational by 2023, with a sales target of €2 billion in 2030.

NFPP and NAFILean natural fiber composite innovations

Since 2003, Faurecia says its high natural fiber-reinforced polypropylene (NFPP) composite materials have been a key solution toward enabling the next generation of vehicle interiors. Compression molded with up to 50% natural fibers, NFPPs are said to reudce weight and CO2 emissions by 50% compared to similar all-plastic products and are designed to achieve the greatest weight reduction without sacrificing performance or mechanical properties; in the past three years alone, NFPPs have helped the company eliminate almost two million kilograms of plastic.

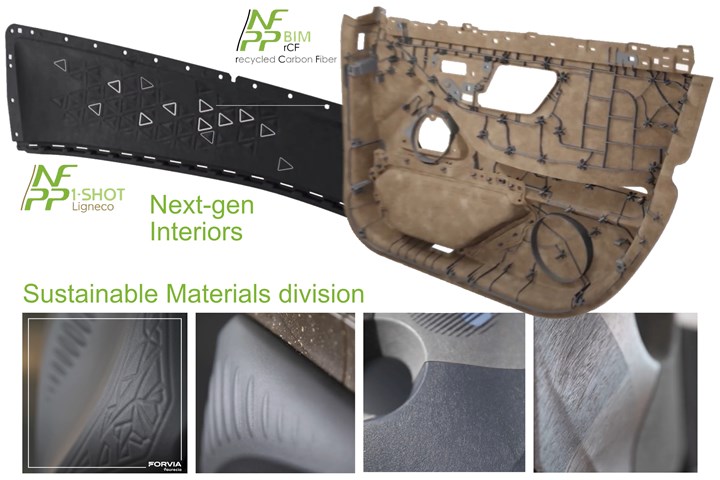

Faurecia’s NFPP 1-Shot Ligneco family of materials enables compression molded parts with upgradable surfaces, such as printing and embossing. Photo Credit: Faurecia video, Sustainable materials – design freedom with NFPP Ligneco

NFPPs are also optimal for creating interior parts in a wide variety of finishes, according to Faurecia, including making the natural fibers visible. The NFPP range can be integrated with all of Faurecia’s latest solutions for vehicle interiors, including radiant panels, smart surfaces and decorative lighting.

NAFILean, launched in 2011, is a recyclable, lightweight natural fiber material that uses hemp fibers. This biocomposite “meets OEMs’ performance and safety requirements,” says Laurence Dufrancatel, innovation materials manager and Sustainable and Smart Product Line core team member in a February 2021 interview on the subject. She also notes that a number of biofibers are suitable (like linen and bamboo). The NAFILean family of products has evolved over the years and continues to do so.

“The NAFILean range has grown from one product in 2011 to four today, with a next generation in the works,” says Dufrancatel. “Each of these improves on the ‘parent product’ by lowering CO2 emissions, reducing weight or opening possibilities for more uses. The original NAFILean products are on average 25% lighter than their conventional counterparts, and save around 28% in CO2 emissions.”

Faurecia is now working on CO2-negative NFPP products which use up to 100% recycled plastic polymers and bring added functionality. It details three such products — NAFILean Stiff, NAFILite, NAFILean R — in the February 2021 report, “Innovation for sustainable interiors”:

- NAFILean Stiff makes for a tougher part that can be used in different settings while still saving 52% of CO2 emissions.

- NAFILite has a microcell structure, with 29% reduction in weight and 43% reduction in CO2 emissions before its use phase.

- NAFILean R, using a 100% recycled plastic [polypropylene] matrix, saves 108% of associated CO2 emissions and is, in effect, a CO2-negative product! Its PP matrix also consists of around 20% organic content, achieving a 25% weight reduction.

NFPP using recycled carbon fiber

Another innovation, rCF NFPP consists of 40% natural fibers, 50% PP and a nonwoven layer comprising 10% recycled carbon fibers. Faurecia’s rCF NFPP is 50% lighter than injected solutions and 25% lighter than standard compression-molded parts. It was a JEC Innovation Award 2021 finalist in the “Automotive and Road Transportation – Exterior” category.

Together, rCF NFPP and NAFILean-R earned Faurecia the German Innovation Award 2022 in the “Excellence in Business-to-Business” competition category. It also won the “Automotive Technologies” category award, “setting standards in recycling and contributing to weight reduction in vehicle interiors and thus to a reduced carbon footprint in automotive construction.”

“We are proud of this award, as it confirms our success in shaping the future of mobility in a more sustainable way,” says Gherardo Corsini, marketing director, Faurecia Interiors. “The increasing demands of our customers for sustainable and recyclable materials encourage us to further intensify our research in this area.”

Pursuing even further weight, emissions reductions

Other novel NAFILean products are under development, such as NAFILean Perf, which will reportedly offer the highest reductions in weight and CO2 emissions yet — 41% and 58% respectively.

NaFILean biocomposites currently equip 17 vehicles — including the Renault Clio, the Alfa Romeo Giulia, the Peugeot 508 and the Land Rover Velar — and can be found in around 13 million cars (additional innovation examples and videos can be located here).

From injection to compression molding

How will innovations for sustainable materials at Faurecia evolve? “In order to reach our objective to reduce the CO2 emissions associated with materials by 87%, we have identified a number of innovation tracks, some of which will bear fruit sooner, and others which will be developed over the coming years,” says Dufrancatel. “Currently, NAFILean products are manufactured through injection processes. We are developing the NFPP family for a new range of interiors components for compression technology, the first generation of which is already in serial production. While compression has its own challenges, it also presents opportunities to develop natural fiber composites using other plants (such as flax and kenaf), and expand the uses of our solutions (in visible parts, for example). The NFPP family offers up to 50% weight reduction and, with up to 45% bio-based content, can halve the CO2 emissions associated with these products. A new generation with 50% recycled content is in development.”

NAFILean materials for injection molding are used in instrument panels and other vehicle interior structures. Photo Credit: Faurecia video, Sustainable materials - NAFILean and NFPP

Between now and 2023, she says, Faurecia is aiming to incorporate more recycled content and more biofibers into NAFILean and NFPP, as well as lightweighting materials and design. In the mid-term, by 2025, the company hopes to tackle visible parts and include more recycled content, improve production processes and recyclability, and work on lean architecture.

“As well as building on the NAFILean and NFPP ranges, we want to innovate for sustainable materials for all interiors components. To this end, we are focusing on acoustics and soft trims, by incorporating biocontent, recycled content and monomaterials to facilitate recycling. In collaboration with FAS as part of Seat for the Planet, we are jointly developing alternatives to leather in automotive seating and reducing the CO2 footprint of covers, as well as biofoams.

“We are also in the early stages of developing systems for chemical and mechanical recycling for plastics,” he continues. “A new business model such as this would allow us to add value in the recycling and reprocessing of our own products. This is still in the very early stages, but we hope to share more soon!”

In May 2022 announcement, Faurecia also signed a Cooperation and Research Agreement with Veolia (Aubervilliers, France) to jointly develop innovative compounds for automotive interior modules, aiming to achieve an average of 30% of recycled content by 2025. Through this partnership, the two companies will accelerate the deployment of sustainable interiors solutions implemented in instrument panels, door panels and center consoles in Europe, leveraging competencies across sustainable compound formulations, stringent automotive architecture requirements, sourcing and innovative treatment of industrial and post-consumer plastic waste. Veolia will start the production of these secondary raw materials at its existing recycling sites in France starting from 2023.

Faurecia anticipates these innovation tracks to drive it into new markets and pique the interest of OEMs. For more details, see:

- “Faurecia’s vision and strategy for CO2 neutrality,” March 2021

- “Spotlight on sustainable materials: NFPP and the next generation of vehicle interiors,” June 2021

- “Faurecia to create cross-Business Group division for sustainable materials,” July 2021

- Faurecia wins German Innvation award 2022 for its sustainable composite materials,” May 2022

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

Faurecia showcases composite hydrogen demonstrator for commercial vehicles at Auto Shanghai event

Seven-tank hydrogen storage system designed to provide more than 700 kilometers of autonomy for long-distance and high-load commercial trucks.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More