Addcomposites adds tape winding to Finland facility for pilot trials

The new capability, which enhances the available level of design freedom, was added to encourage manufacturers to develop new innovations using tape winding.

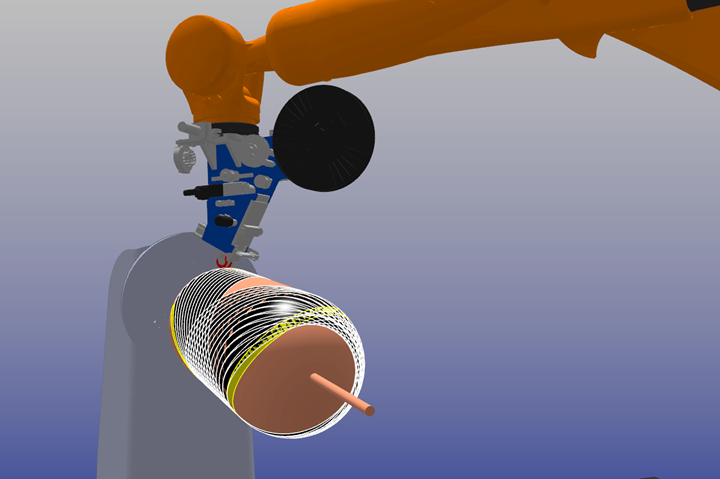

Photo Credit: Addcomposites

Addcomposites Oy (Espoo, Finland), the provider of the automated fiber placement (AFP) system, AFP-XS, announces that it has added a tape winding capability at its Finland facility, with the primary goal of enabling more pilot trials for manufacturers who are looking to validate the manufacturing feasibility of their innovative design and/or proving the benefits of their layup configuration. “The addition of the rotational positioner adds another order of magnitude to complexity of the parts we are able to produce and showcase for any customers looking to validate their process and design,” says Pravin Luthada, Addcomposites CEO.

With the tape winding addition, users are able to develop complex shapes for a variety of end markets such as pressure tanks for the storage of hydrogen, propellants or compressed air, tubes/pipes for water, oil and gas, structural components such as booms, housings, grid structures, interstage and axis-asymmetric parts such as ducts. Unlike conventional fiber winding processes, Addcomposites says tape winding offers new levels of freedom to use non-geodesic fiber orientations, add local reinforcements for inserts, mounting points, etc., produce linerless tanks and use more sustainable/reusable materials like thermoplastic composites.

“This investment is the next logical step to take in becoming one of the best resources for the additive manufacturing of composites, regardless of material, part size or shape,” adds James Kuligoski Addcomposites technical sales engineer. “It also allows us to better support and compliment our partners who are experimenting in this area more and more.”

To approach Addcomposites with project proposals, the company suggests reaching out to either Luthada (Pravin.luthada@addcomposites.com) or Kuligoski (james.kuligoski@addcomposites.com). Some prior information is appreciated — including a CAD or drawing of the part and/or layer and fiber orientation details — and everything shared is protected by NDA. Further, in most cases there will be no charge for the initial study; however, performance of pilot production will incur some material and labor costs.

Addcomposites notes that presently, partners SAM|XL (Delft, Netherlands) and Compositadour (Bayonne, France) are able to conduct similar trials using a seventh rotational positioner.

Related Content

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

Rocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

-

ATLAM combines composite tape laying, large-scale thermoplastic 3D printing in one printhead

CEAD, GKN Aerospace Deutschland and TU Munich enable additive manufacturing of large composite tools and parts with low CTE and high mechanical properties.