AFPT, Alformet advance bending of thermoplastic composite tubes

Specialists in AFP and LATW discuss process and lessons learned for new applications in CFRTP parts.

Fiber-reinforced polymer (FRP) composite products continue to gain importance in many markets due to their low specific weight, high specific strength/stiffness and resistance to corrosion, chemicals and, with certain polymers, high temperatures. FRP composites using thermoplastics (FRTP) offer additional advantages, including vibration dampening, impact resistance, reusability/recyclability and the ability to reform or reshape the parts.

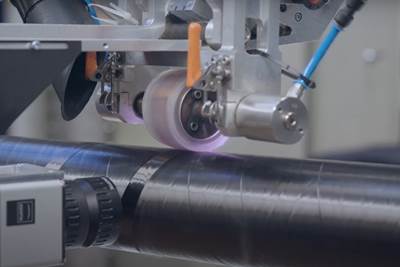

AFPT (Dörth, Germany) has decades of expertise in the application of unidirectional (UD) thermoplastic composite tapes — specifically continuous fiber-reinforced thermoplastic (CFRTP) UD tapes — in the automated fiber placement (AFP) process of laser-assisted tape winding (LATW). [NOTE: CW uses CFRTP to denote carbon fiber, while AFPT’s use of CFRTP can denote glass, carbon or other fiber, as long as it is continuous.] This process enables a high level of automation, productivity and quality control. It also allows straight tubes with tailored properties to be further processed to either change the shape of the cross-section and/or add axial bends.

A whitepaper exploring the process steps and considerations for reshaping and/or bending CFRTP tubes has been released by T. Mimpen from Alformet (Drunen, Netherlands) and F. Henne from AFPT. Below is a quick summary and link to the full paper.

Practices for bending CFRTP tubes

The ability to post-form CFRTP tubes is quite similar to metal bending technology, yet the behavior of the material is different and affects the specific methodology required to obtain the best results. For example, it is important to know and understand the effect and the behavior of the fibers within the thermoplastic matrix before and during post-forming, and furthermore to predict the final angle of the bent laminate with a mathematical formula.

Successful bending of CFRTP tubes starts with the proper sequence of process steps:

-

- Assemble internal and external support of the tube.

- Heating the assembly above the melting temperature of the thermoplastic matrix.

- Bend the assembly.

- Cool the assembly.

- Remove supports.

An important difference compared to metal is the fact that the bending process takes place above the melt temperature of the thermoplastic matrix, while it is in a molten state. Thus the tube shape can be altered without high forces but is also vulnerable to unintended changes. Especially during tube bending, buckling of the CFRTP tube can occur if the material cannot withstand the compressive forces on the tube’s inner bending radius.

To control this effect and prevent buckling of the tube during the bending process, the inner and outer surfaces of the tube must be supported. AFPT Group uses sand to support the inner part of the tube because it combines the ability to resist both shear and compression. However, for this to be effective, it is essential to enclose the sand inside the CFRTP tube. Alternative approaches use silicone or compressed air, but sand offers a perfect combination of high flexibility and low compressibility, especially during part development.

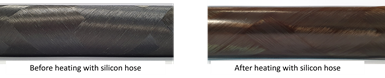

A silicone hose or sleeve placed around the CFRTP tube provides external pressure and smooth finished surface. Photo Credit: Alformet

On the outer part of the tube, a silicone hose or sleeve is used to create a compressive pressure around the circumference of the CFRTP tube. To achieve the compressive force, the inner diameter of the silicone hose is roughly 25% smaller than the outer diameter of the CFRTP tube. A positive, collateral effect of the resulting compressive force applied during the heating of the tube is that the outside surface becomes smooth from the melting of the thermoplastic matrix.

Outer surface of CFRTP tube before and after heating using a silicone hose/sleeve. Photo Credit: Alformet

Heating can be done either locally in the bending zone or globally in an oven. The temperature and duration of the heating process depends on the thermoplastic material, the size of the part — i.e., the volume of the heated tube — and the capacity of the heating device used.

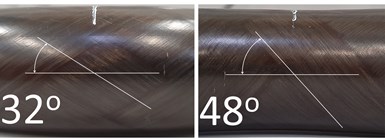

After heating, the CFRTP tube is ready for reshaping or bending. Generally, it is possible to execute the bending manually, as it requires only a small force. Any half pipe shape of the final form is sufficient for repeatability but the design of the mold must compensate for potential springback effects during demolding. The springback effect varies depending on the material used, the winding angle applied during LATW, the tube bending radius and the wall thickness of the tube. Once the temperature has cooled to below the glass transition temperature (Tg) of the thermoplastic matrix, the risk of changes in the shape or damaging the composite is very small.

Wrinkling

The main defect that can occur during bending and reshaping of CFRTP tubes is wrinkling on the inner bending radius. In addition to poor aesthetics, these wrinkles have a huge impact on the strength and stiffness of the part because the fibers undulate and will not contribute effectively to load transfer. There are a variety of factors that can contribute to wrinkling and need to be considered.

If the sand (or other medium) inside the CFRTP tube cannot provide enough resistance during the bending process, the likelihood that wrinkles will form is very high. In contrast, the compressive force on the outside of the tube contributes to the prevention of wrinkles during the bending process. Additionally, a silicone outer sleeve protects the thermoplastic matrix from oxidation during the heating process and creates a smooth surface at the outside of the CFRTP tube.

A 25-millimeter carbon fiber-reinforced polycarbonate CFRTP tube bent into an S-shape after heating for 45 minutes at 225°C. Photo Credit: Alformet

The winding angle of the UD tape in each layer of the CFRTP tube also has an influence on the ability to bend CFRTP tubes without having wrinkles. Typically, winding angles between 30 and 60 degrees will give good bending results as well as desired stiffness in the final shape.

The thermoplastic matrix plays an important role as well. The viscosity of the thermoplastic matrix at the temperature during bending is crucial for the mobility of the fibers to move and reposition. AFPT Group has produced successful bending tubes made with polypropylene (PP), polyamide 6 and 12 (PA6, PA12) and polycarbonante (PC) thermoplastic matrices using carbon fiber reinforcement. Glass fiber reinforcements have not yet been trialed but are expected to perform similarly except that the expansion coefficient may produce higher springback effects.

A faster heating cycle will increase productivity but also the likelihood of wrinkles and will reduce the ability to obtain a perfect outer surface quality. The dissipation of heat by the medium (e.g., sand) inside the tube must be taken into account for the duration of the heating process. Note, the effect of the heating and cooling process on the properties of the thermoplastic matrix has not been part of the scope of this work. While results show that the porosity is reduced in the heating cycle, which is positive for the mechanical properties, more extensive study is needed. It is also expected that the effect of the heating and cooling cycle will also depend on whether the thermoplastic is amorphous versus semi-crystalline, with the latter requiring more precision in the cooling rate to obtain the required crystallinity for high-performance mechanical properties.

Future opportunities, development

FRTP composite parts have huge potential due to their high strength and stiffness, lightweight, recyclability and low maintenance. The ability to reshape and bend such parts by using continuous fiber-reinforced thermoplastic (CFRTP) materials opens new applications. For example, in construction elements, reshaped/bent CFRTP tubes can replace separate connector elements (e.g., bolts/nuts), saving time and cost in the assembly of furniture parts (e.g., chair base elements), poles in buses and trains, bicycle structures and high-pressure hoses and connectors. Even further expansion is possible by exploring local reshaping not only in tubes but in other CFRTP products.

AFPT and Alformet have developed significant knowledge in how to execute the bending/reshaping process and are also exploring further development by automation and fine-tuning of the steps described here. To read the full version of the whitepaper, visit: https://www.alformet.com/blogs/bending. AFPT Group invites interested parties to collaborate in continuing this development. Please contact info@alformet.com.

Related Content

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

AFPT participates in LeiWaCo project for economic production of thermoplastic composite hydrogen tanks

Laser winding/welding will help 3-year project develop cross-industry container-based transport/supply unit for cryogenic liquid hydrogen, aiming for TRL 5 via demonstrator manufacture and testing.

Read MoreChallenges of laser-assisted tape winding of thermoplastic composites

Practical solutions for process-related challenges in LATW, which has great potential for pressure vessels and storage tanks.

Read MoreAFPT GmbH acquires Alformet BV, celebrates 20 years

Combined know-how and company visions, and the founding of Alformet GmbH, aim to enhance the availability and delivery of high-quality fiber-reinforced thermoplastic composite solutions to customers.

Read More