Airborne announces composites manufacturing partnerships

At JEC World 2018 Airborne unveiled numerous business partnership plans for automated honeycomb potting and cutting/kitting solutions.

Airborne (The Hague, the Netherlands), supplier of automated and digital manufacturing solutions for composites, recently announced numerous partnerships at JEC World 2018 in Paris, France.

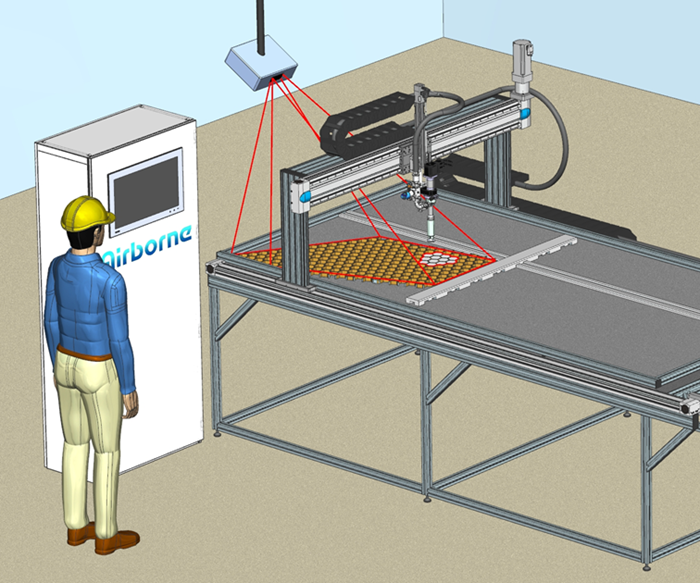

Airborne and ViscoTec partner on automated honeycomb potting

Airborne and ViscoTec (Töging a. Inn, Germany), supplier of dosing pumps and dosing systems for medium to high-viscosity fluids, announced March 6 they are entering a business partnership to develop and supply an integrated automated solution to fill honeycomb cores with potting compounds. With this partnership a fully automated integral solution can be offered to the composite manufacturing industry enabling a lower weight of the end-product and a drastic reduction of labor, material consumption and non-conformities.

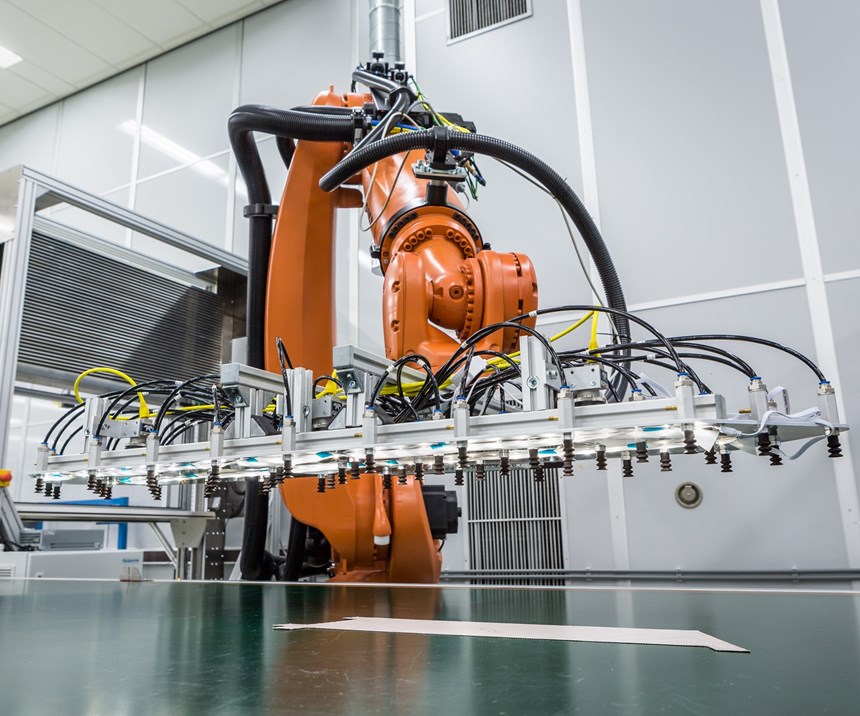

Airborne and Plataine partner for automated composites kitting solution

Airborne and Plataine, leading provider of Industrial IoT and AI-based optimization solutions for advanced manufacturing, sealed a business partnership March 7 for automated composites kitting solutions. By integrating Plataine’s Cut Plan Optimization Solution into Airborne’s automated kitting system, composite material utilization can be optimized to its ultimate limits resulting in minimized material waste and optimized factory logistics.

One of the key advantages of an automated kitting system is that it can facilitate the use of Plataine’s strong expertise in the field of digitizing and optimizing complex manufacturing processes using AI-based algorithms that create optimized cut-plans (nesting), with the ability to mix product plies using the same raw material, and create an integrated method for dynamic nesting. Adopting these strategies to minimize material waste and optimize factory logistics, comes to its fullest extent when integrated into Airborne robust hardware solution for automated kitting. The new partnership displays the ultimate example of system optimization by perfectly aligning hardware and software.

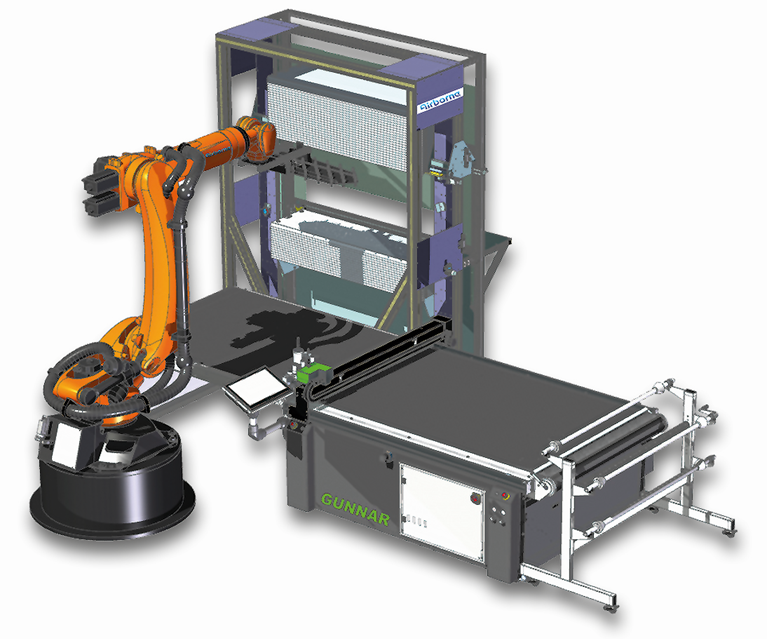

Airborne and Gunnar join forces in automated ply cutting and kitting for composites

Airborne and Gunnar (Altstätten, Switzerland) announced March 7 they are entering a business partnership for developing and supplying integrated automated ply cutting, handling, stacking and sorting solutions for composites and advanced materials. With this partnership, fully integrated systems can be offered to the composite manufacturing industry, enabling maximized composite material utilization at highest process secureness.

“Airborne and Gunnar envisioned the same roadmap for automated and digital composite manufacturing processes,” says Arno van Mourik, CEO Airborne. “By partnering we are able to offer our customers turnkey fully integrated cutting and kitting solutions based on a modular and scalable concept for highest process flexibility at a minimized footprint leading to significant cost reductions.”

Related Content

-

Aptco Technologies supports supply of Compcut cutting machines

The pan-European partner to Sharp & Tappin will actively promote, sell and support the composite cutting solution to meet rising demand across Europe.

-

JEC World 2023 preview: Techni-Modul Engineering

Smart Control automated technology enables high-rate, AI-driven kitting, stacking and layup of preforms and composite parts.

-

Optimized, automated manufacturing concepts for composite parts, SMC semi-finished materials

JEC World 2024: The AutoCut Pick&Place and Cube SMC line from Schmidt & Heinzmann aim to deliver more modernized manufacturing capabilities with improved efficiency and process control.