Airbus starts production of Galileo Second Generation satellite featuring composites

Manufacturing of six state-of-the-art GNSS satellites uses composite structures from Beyond Gravity, will augment current Galileo constellation.

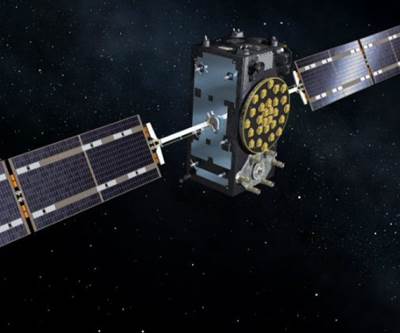

Galileo Second Generation satellite. Photo Credit: Airbus

Full production has begun on the six Galileo Second Generation (G2) satellites at Airbus’ site in Friedrichshafen, Germany, with the arrival of the first satellite Flight Model structure from Beyond Gravity (Zurich, Switzerland). Galileo is a highly precise satellite navigational system that provides meter-level accuracy to more than four million global users. The G2 satellites will add enhanced capabilities to the current 38 Galileo satellites in orbit.

The Flight Model structure is similar to what Beyond Gravity has supplied for the MetOp 2nd Generation weather satellites (6-meter-high, 1,000-kilogram assembly of 24,000 parts) featuring a lightweight sandwich construction of aluminum honeycomb bonded to carbon fiber-reinforced polymer (CFRP) skins. These lightweight composite structures withstand the harsh loads during launch as well as the extreme temperatures, temperature fluctuations and vacuum conditions in space. After preparation, the G2 Flight Model structure will be mated with other hardware and systems during final integration and testing at Friedrichshafen. The Galileo G2 satellites are scheduled for launch in the coming years to support the initial deployment and validation of the G2 system.

“After the successful design phase, we are now kicking off production in earnest of the state-of-the-art Galileo G2 satellites,” Jean-Marc Nasr, head of space systems at Airbus, says. “Our teams in Friedrichshafen are working with engineers across Europe to meet the challenging schedule and finalize these sophisticated satellites which will further improve the global Galileo system opening up even more opportunities for services on Earth.”

To meet the demanding schedule to deliver all six satellites in less than 2 years, Airbus has developed a coordinated production program to leverage the spacecraft manufacturing, integration and testing expertise across Airbus sites including Backnang (near Stuttgart), Friedrichshafen, Madrid, Ottobrunn (near Munich) and Toulouse. The second satellite structure is due to arrive in early 2024 and the third toward the end of next year. Airbus’ modular approach to the manufacturing of the G2 satellites will see three spacecraft being produced in parallel at any one time.

The G2 satellites will incorporate enhanced navigation antennas which will help improve accuracy of the flagship European Global Navigation Satellite System. The spacecraft, equipped with electric propulsion for the first time and higher strength navigation antennas, will also feature fully digital payloads which will be easily reconfigured in orbit, enabling them to actively respond to the evolving needs of users with novel signals and services.

The satellites, which benefit from Airbus’ heritage of the highly reliable Eurostar series of telecommunications satellites, will also incorporate six (rather than four) enhanced atomic clocks as well as intersatellite links, enabling them to communicate and cross-check with one another. This is intended to offer decimeter-scale precision positioning for users around the world. They will be controllable with an increased data rate to and from the ground and equipped with advanced jamming and spoofing protection mechanisms to safeguard Galileo signals. The spacecraft will operate in orbit for 15 years

The Full Operational Capability phase of the Galileo program is managed and funded by the European Union. The European Commission and ESA have signed an agreement by which ESA acts as design authority and system development prime on behalf of the Commission.

Related Content

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

Airborne to manufacture solar array panels for Galileo satellites

Airborne Aerospace has been awarded a contract to manufacture substrate panels for the solar arrays of 12 new Galileo FOC satellites.

Read MoreBeyond Gravity innovates space with reusable payload fairing

Reuse of composite second stage half-shells could make rockets more accessible to various companies and support more frequent launches.

Read MoreComposite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

Read More