Arris Composites secures $48.5 million new funding to accelerate Additive Molding technology

The company plans to open facilities in the U.S. and Taiwan, and to use its composites manufacturing process to build consumer electronics.

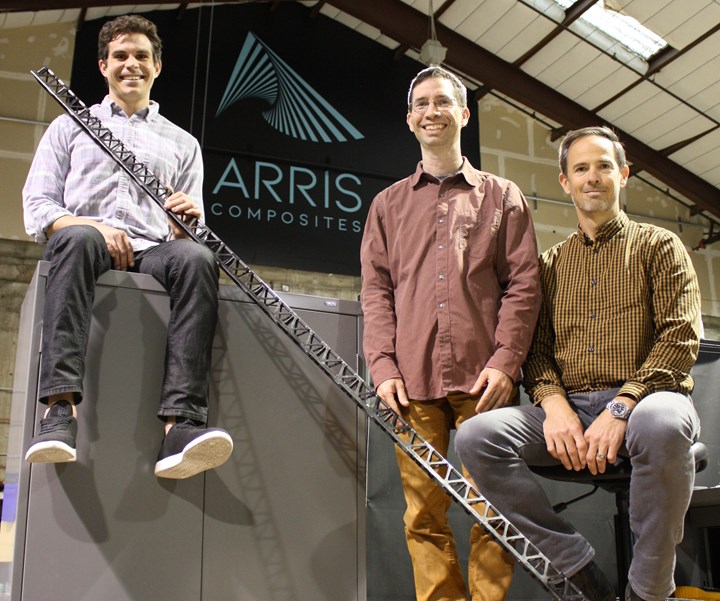

Source | Arris Composites

Arris Composites (Berkeley, Calif., U.S.) reported on April 10 that it has received $48.5 million in Series B funding. With the new funding, Arris says it will be expanding its proprietary composite manufacturing capabilities (see “Additive Molding promises mass-produced high-performance composites”) and opening facilities in the U.S. and Taiwan, the latter to serve the demand of the consumer electronics industry.

The round was led by Taiwania Capital with participation from return investor New Enterprise Associates (NEA), which led Arris Composites’ $10 million Series A round in January 2019, alongside Valo Ventures and Alumni Ventures Group (AVG).

In addition, Carl Bass, former Autodesk CEO, will join the board of directors as an independent board member. Carl has been involved with Arris since 2017 as an angel investor, advisor and research collaborator while the company incubated in his personal machine shop.

“Since we began working with Arris Composites in 2018, we’ve been impressed with the maturation of their manufacturing technology and the intense interest and enthusiasm we’ve seen from top brands in the consumer, automotive, aerospace and other industries in leveraging Arris’ manufacturing methods for next-gen, not-yet-released products,” says Greg Papadopoulos, Venture Partner, NEA and former Chief Technology Officer, Sun Microsystems. “High-performance composites that can be mass-produced in new ways hold incredible promise for all kinds of products.”

A portable electronic device is likely to be the first Arris manufactured product available to the public.

Founded in 2017, Arris Composites enables the mass-production of high-strength and light-weight composite parts through its proprietary Additive Molding manufacturing technology. With this new process, advanced carbon fiber materials can be produced at the same speed as plastic molded products, Arris says. The company has also developed tools for in-house design collaboration and application engineering teams.

Potential applications are said to include those in the consumer, automotive, industrial, aerospace and transportation industries. Arris says its fastest-growing market is consumer electronics, where next-gen devices are being designed to be lighter, smaller and smarter. The company says that a portable electronic device is likely to be the first Arris manufactured product available to the public.

“When NEA introduced us to Taiwania Capital, it was clear they had deep manufacturing expertise, as well as a track record scaling up new high-volume consumer electronics technologies,” says Ethan Escowitz, CEO and founder of Arris Composites. “The alignment of our organizations was immediately evident and I knew they were an ideal partner to assist in scaling-up production for our consumer electronics customers.”

“What made Arris Composites appealing to us is their ability to make consumer electronics products that were simply not possible with previous manufacturing technologies,” says Huang Lee, managing partner at Taiwania Capital and Arris Composites board member. “Despite major advances in the electronics within portable devices, the structures have not changed very much, until Arris.”

In addition, Arris Composites says it is employing a new generation of recyclable composites and has developed a novel method of designing products with the end in mind so the waste stream from today’s products becomes the feedstock for future products.

Related Content

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

.jpg;width=70;height=70;mode=crop)