AZL Aachen conducts study to evaluate the biocomposites market

Comprehensive Joint Market and Technology report identifies CAGR for natural fibers, biopolymers and bio-based composites market will reach 22.7% between 2021 and 2026.

Photo Credit, all images: AZL Aachen

Do you know the expected CAGR for the natural fibers, biopolymers and bio-based composites market? The rising demand for more sustainability is just one driving factor — but what’s in for composites and is there potential for bio-based composites?

This question led to AZL Aachen’s (Germany) Joint Market and Technology Study conducted with nine industrial companies, with the goal of obtaining a comprehensive evaluation of the potential of bio-based composites.

Within this study, AZL segmented and analyzed various markets and investigated technical requirements of existing parts and products, as well as future applications; provided insights into today’s value chains, processes and materials; and highlighted strengths and challenges for bio-based composites over traditional materials. Finally, together with the participating companies, which included REHAU (Muri bei Bern, Switzerland), Asahi Kasei (Tokyo, Japan), Johns Manville (New York, N.Y., U.S.), Mahr Metering Systems (Charlotte, N.C., U.S.) and several material manufacturers, AZL Aachen identified more than 30 high-potential applications and analyzed four chosen applications in business cases.

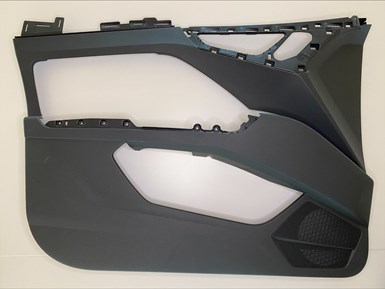

One of the applications which was highly requested was the automotive door module. The report resulted in 500+ pages of markets, technologies, materials, processes, potentials and costs while taking eco-KPIs (key performance indicators) into account; it is available for purchase. Interested parties can reach out to Alexander Knauff (contact info below).

Bio-Based Composite Door Module project.

As a next step, under a Bio-Based Composite Door Module project, AZL Aachen and industrial companies will investigate different material combinations and test on the coupon level, to determine which combinations fulfill the requirements of an automotive door module. Subsequently, AZL plans to produce a demonstrator to show the potential process chain. At the end of the nine-month project, AZL will carry out an economic and ecological analysis of the door module.

The AZL will have an open workshop on April 28, 2022 for interested companies, where questions can be addressed and the project strategy will be discussed.

For more information on the topic and if you are interested to join the workshop, you can get in touch with Alexander Knauff, alexander.knauff@azl-aachen-gmbh.de, +49 241 475735 16

This post is courtesy of the CompositesWorld and AZL Aachen GmbH media partnership.

Related Content

-

European boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

-

BiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

-

Okom wrks labs works with Autodesk for mycelium-based composite commercialization

Research Residency program will further refine material properties and manufacturing processes to support the startup’s efforts of providing high-performance, regenerative biocomposite solutions.