AZL Aachen GmbH | Excellence in Lightweight Production

Campus Boulevard 30

Building Part 3B, 4th Floor

Aachen, 52074 DE

+49 241 475735 0

info@azl-aachen-gmbh.de

azl-lightweight-production.com

About AZL Aachen GmbH | Excellence in Lightweight Production

Offers an international industrial composite network of +80 companies and 9 research institutes and provides industrial services including studies and benchmarks, technology advisory and development projects using its strong network at the RWTH Aachen Campus, worldwide leading technical university.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

AZL Aachen GmbH | Excellence in Lightweight Production Supplies the Following Products

- CAD/CAM/CAE design

- Consulting, business development/acquisition

- Consulting, environmental

- Consulting, health and safety

- Consulting, materials

- Consulting, process development

- Consulting, procurement/purchasing/specification

- Consulting, structural design

- Finite element modeling/analysis (FEM/FEA)

- Impact-testing equipment

- Market research

- Materials analysis

- Newsletters/directories

- Other services

- Pressure vessels

- Product design

- Prototyping

- Testing, materials

- Testing, product

Editorial, News, and Products

-

AZL announces follow-up projects on electromobility casings, thermal runaway

AZL continues series of projects to develop the next generation of battery casings for electromobility, encourages interested companies to join consortias before Sept. 11th kick-off.

-

AZL opens new project in cell-to-pack composite battery enclosures

AZL specialists are to kick off new project consortium Oct. 27, 2022 geared toward developing new battery enclosure concepts for cell-to-pack technology. Interested companies can still apply for participation.

-

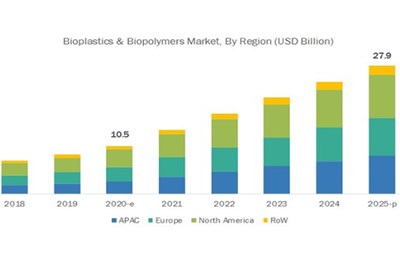

AZL Aachen conducts study to evaluate the biocomposites market

Comprehensive Joint Market and Technology report identifies CAGR for natural fibers, biopolymers and bio-based composites market will reach 22.7% between 2021 and 2026.

-

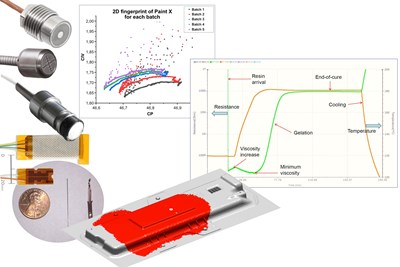

Sensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

-

AZL Aachen with 46 industry partners successfully complete multi-material battery casings project

Multi-material solutions, including consideration of composites, open up high potential for cost and weight savings for battery casings, with follow-up projects to come in 2022.

-

AZL Aachen webinar: Designing with thermoplastic composites

AZL Aachen is hosting the fifth webinar in its Lightweight TechTalk series, titled, “Best Practices in Lightweight Design with Thermoplastic Composites” on Thursday, Jan. 28, 1:00-2:45 p.m. (13:00-14:45) CET.

-

People in Composites: November 2020

CW’s November monthly people roundup include new appointees for Lilium, ACMA, Beckers Group, AZL, Hexion and Eckhart.

-

AZL, EconCore, Audi partner to develop composite battery casings

A new project aims to identify potential opportunities and challenges for composite materials within the electric vehicle battery enclosure market.

-

Teijin joins AZL Partner Network

Participation with the cross-industry network’s upcoming multi-material battery casing project and will accelerate Teijin’s automotive composites expertise.

-

AZL Aachen investigates potential for bio-based composite materials

The five-month market and technology study will start on October 22, 2020 and is open to interested companies.

-

AZL begins multi-material battery casing project for electromobility

The eight-month joint development project will begin with a concept study for the final design and manufacture of the prototype. Interested companies can initiate participation until October 22, 2020.

-

ITA acquires composites 4.0-enabled BIAXTRONIC warp-knitting machine from Karl Mayer

This latest technology will aid development of open-meshed textile grids and non-crimp fabric structures for composites and concrete reinforcements.

-

AZL Aachen webinar: Tape integration into injection molding

AZL Aachen is hosting the third webinar in its Lightweight TechTalk series, titled, “Tape Integration Into Injection Molded Parts,” on Thursday, Aug. 13, 5:00 am-6:20 am EDT (11:00 am-12:20 pm CET).

-

Roth Composite Machinery becomes AZL partner for winding technology study

Roth Composites Machinery will support the joint study to evaluate potential composite technologies for composite pressure tanks.

-

Conbility: Mass production of composite tape laminates

RWTH Aachen spin-off scales up production for low-cost, in-situ consolidated composites as inserts for lighter, cheaper injection-molded parts.

-

Composites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

-

Digital thread vs. digital twin

Visualizing the difference between digital representations and data flows and understanding the applications that are changing composites manufacturing and business models.

-

Augmented reality system facilitates FRP component preforming

The software makes exact alignment and position of materials directly visible on the component.

-

Bio-based hybrid tapes assessed for lightweight applications

A project of AZL’s partner institute, ITA, integrates flax fiber reinforcement with a PA11 resin matrix. Targeted end markets include automotive and wind energy.

-

AZL, IKV launch SMC data bank and testing project

Researchers and partner companies aim to standardize the provision of engineering data for long fiber-reinforced sheet molding compounds (SMC).

-

Research project reports potential for tape inserts in injection molding

The research consortium, led by the Aachen Center for Integrative Lightweight Production and the Institute for Plastics Processing at RWTH Aachen University, will present its results at K 2019.

-

Research project claims CFRP part production at half cost, faster throughput

The iComposite 4.0 project, led by Schuler AG and its partners, has tested its new production process with carbon fiber-reinforced plastic automotive prototype parts.

-

AZL production system wins JEC Innovation Award

AZL’s UItra-Fast Consolidator Machine, winner of the JEC Innovation Award 2019 for Industry/Equipment, will be the subject of further research into commercialization of the machine.

-

Thermoplastic overmolded thermosets, 2-minute cycle, one cell

Adhesive-free, functionalized hybrid composites enabled by industry-first, integrated molding cell.

-

JEC World 2019 preview: Institut für Textiltechnik at RWTH Aachen University

The Institute für Textiltechnik at RWTH Aachen University (ITA) and the Aachen Center for Integrative Lightweight Construction (AZL, Aachen, Germany) will demonstrate expertise in glass fibers, preforms and textile concrete at their joint booth at JEC World 2019.

-

Carbon fiber will enable air taxi eVTOLs

Aircraft and autos have indeed faced CFRP production woes, but new tech opens door for both.

-

Study looks at composites in the furniture industry

AZL announces study aimed at understanding the selection process of furniture designers in order to bring composites to the market as an alternative to conventional materials.

-

Fast manufacturing of tailored composite blanks

AZL and 12 partner companies have completed a research project to develop a new machine prototype allowing increased speed for manufacturing tailored composite blanks.

-

AZL and IKV explore thermoplastic tapes in injection molded parts

Study explores how thermoplastic tapes might reduce costs and increase performance of injection molded parts.

-

Michelman to partner with AZL Aachen GmbH

Michelman’s latest move is part of its partnership strategy to further advance and improve composite development throughout the industry.

-

iComposite 4.0 — cutting composites cost by 50%

An intelligent, integrated process using 3D fiber spraying, inline inspections/simulation and embedded RFID chips to cut scrap and rejections for structural HP-RTM epoxy parts.

-

Fraunhofer and Conbility join forces to commercialize tape layer

Two AZL Aachen GmbH partners have joined forces for commercialization of a tape-placement and tape winding system.

-

New consortium studies energy storage

With a kick-off on January 30, 2018, AZL Aachen GmbH (Aachen, Germany), in cooperation with 19 participating companies as well as RWTH Aachen University and RWTH spinoff company CONBILITY GmbH (Aachen, Germany), has launched an international market and technology study.

-

AZL establishes new workgroup on composites in buildings and infrastructure

The meeting in January is open to interested companies from the composite industry as well as the building and infrastructure markets.