BASF, Toray Advanced Composites sign supply agreement

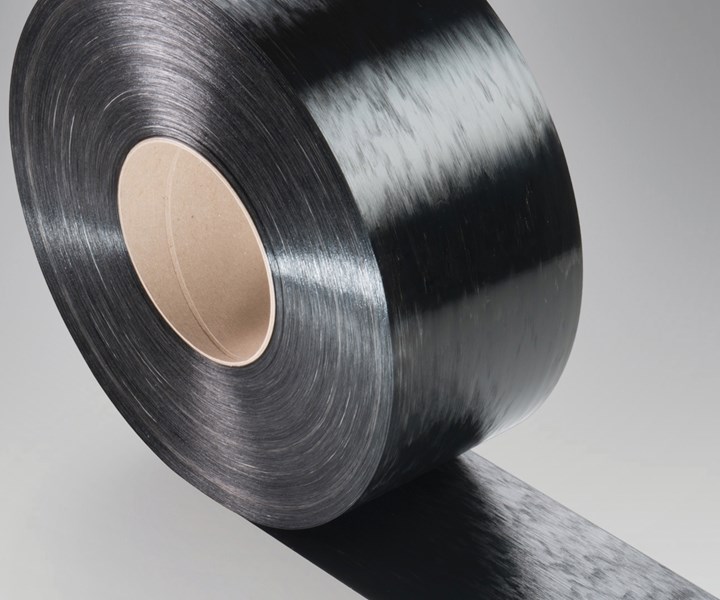

Toray Advanced Composites will produce continuous fiber-reinforced tapes using BASF thermoplastic resins, targeting automotive and industrial applications.

Source | BASF and Toray Advanced Composites

Toray Advanced Composites (Morgan Hill, Calif., U.S.) and BASF (Wyandotte, Mich., U.S.) have signed a manufacturing and supply agreement focused on the production of continuous fiber-reinforced thermoplastic tapes for the automotive and industrial markets. Toray Advanced Composites will produce glass fiber- or carbon fiber-reinforced tapes using BASF’s Ultramid PA6 (polyamide) engineering thermoplastics.

“BASF has been a valued partner for Toray Advanced Composites for many years. This new supply agreement strengthens our ability to make the highest quality tapes, affordably, for our customers,” says Keisuke Ishii, CEO of Toray Advanced Composites.

According to the companies, this supply agreement enhances manufacturing capacity, providing wider commercial availability of continuous fiber-reinforced thermoplastic materials, which they say will will enable the adoption of advanced materials for lightweight, structural components in a range of industrial markets. For example, the companies say that automotive manufacturers can use the new materials to design and rapidly produce optimized components at a lower cost, while using the latest fabrication methods such as automated stamp forming and overmolding.

“By developing innovative lightweight, composite material technologies for automotive applications, this partnership underlines both companies’ strong commitment to drive sustainable solutions,” says Jeff DeAlmeida, VP, transportation industry, performance materials North America, BASF.

Toray Advanced Composites’ continuous fiber-reinforced thermoplastic materials are said to be compatible with a range of BASF’s Ultramid compounds, enabling more efficient, multifunctional parts to be produced in fewer steps and with less labor compared to more traditional methods.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

.jpg;width=70;height=70;mode=crop)