Clean Sky 2 FUSINBUL project develops full-scale, carbon fiber pressure bulkheads

Two 3.5-meter pressure bulkhead demonstrators incorporate advanced layup techniques with the goal of increasing serial production capabilities for fuselage manufacture for regional aircraft.

Clean Sky 2’s FUll Scale INnovative pressure BULkheads (FUSINBUL) project, funded by the EU’s Horizon 2020, aims to develop and validate two advanced manufacturing processes to reach a significant reduction in the overall production cost and flow for composite pressure bulkheads for regional aircraft. Recently, two full-scale 3.5-meter pressure bulkhead demonstrators were developed for full barrel testing and certification (Fig. 2).

The FUSINBUL consortium is formed by Fidamc (The Composites Research, Development and Application Centre, Madrid, Spain), Metitalia (Angri SA, Italy), OMPM (Italy) and Sertec, with Leonardo Aircrafts (Rome, Italy) acting as the topic leader. Fidamc is project coordinator and is responsible for the manufacture of the composite bulkheads. Metitalia and OMPM are in charge of the detailed design and manufacturing of the tooling and metallic parts required for the demonstrators’ tests. Sertec is responsible of the preliminary design and release of the drawings for the tooling.

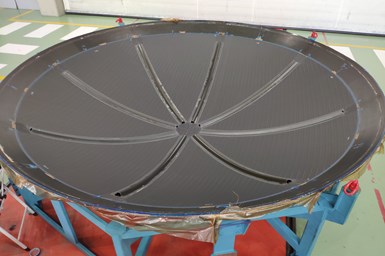

Fig 1. Composite pressure bulkhead demonstrator delivered to Leonardo for ground testing. Photo Credit, all images: Clean Sky 2

The bulkheads will be manufactured using carbon fiber-reinforced plastic (CFRP) and advanced layup techniques, according to project partners, with the goal of increasing serial production capabilities for bulkhead development. Two different technologies are going to be use for the bulkheads’ manufacture:

- CFRP prepreg with epoxy resin using a cobonding process (cured omega stringers will be cobonded to a fresh skin laid up by automated fiber placement (AFP)).

- Dry fiber CFRP using out-of-autoclave (OOA) liquid resin infusion. Cured omega stringers and cured skin (laid up via AFP) are infused separately, and then joined by rivets (see video above).

Fig 2. Front view of the composite bulkhead (top). Back view of the bulkhead with omega stringers integrated (bottom).

To manufacture these elements, the tooling design has been taken into account to meet the needs of the manufacturing processes and industrial requests. For example, a cast aluminum tool has been developed by lost foam casting — a process in which molten metal evaporates a foam mold being held still with sand. A precise and robust indexing split-and-seal system eliminates gap or step.

The bulkhead demonstrators have been delivered to Leonardo’s facilities to start the final assembly of the on-ground demonstrator (Figs. 1 and 2).

Related Content

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.