Creative Composites supplies SMC parts for zero-emission vehicles

Chosen for SMC’s range of benefits, Creative Composites has currently manufactured SMC front fenders and doors, designed to offer longevity, flexibility and robustness against everyday dents and knocks.

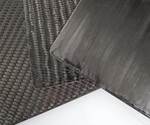

Creative Composites' SMC molding technology. Photo Credit: Creative Composites

Advanced composites manufacturer, Creative Composites (Lisburn, Northern Ireland) reported on Nov. 5 that it is supplying sheet molding compound (SMC) parts for what is says is a revolutionary zero-emissions commercial van.

Working in collaboration with one of the U.K.’s leading OEM’s for several years on this project, Creative Composites notes that the use of SMC compression molded parts have been chosen for the material’s range of important benefits, including longevity and lightweighting to improve fuel efficiency, lower vehicle operating costs and to extend the vehicle’s zero power range. Some of these parts include SMC front fenders and doors, designed to offer longevity, flexibility and robustness against everyday dents and knocks.

“These hybrid vehicles are cleverly designed to optimize performance and styling while reducing emissions and operating costs,” says Richard Ennis, chairman, Creative Composites. “Our specialist Vehicle Design team has been working closely with our client’s engineers to develop, design, prototype and validate various composite SMC parts.”

SMC compression molded parts also deliver added benefits such as class A surface finishes, unlimited design flexibility, impact, heat and corrosion resistance and noise reduction. These advantages, says Creative Composites continue to help SMC gain market share over steel, aluminum and other plastic alternatives.

Further, SMC manufacturing offers precise dimensional accuracy, repeatability and fast cycle times. To fully exploit the company’s larger compression molding presses (with up to 3000 tonnes of pressure) the Creative Composite engineers is concentrating on optimizing design for manufacture and component consolidation, to achieve vital cost savings for clients.

Looking to the future, Creative Composites says it is looking forward to further global collaborations with automotive, van, truck, bus, materials handling equipment and last mile delivery OEMs. The company is focused on improving the sustainability and eco credentials of vehicle components by offering a range of innovative, new lightweighting solutions including low-density SMC and ultra-low density SMC.

Related Content

-

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

-

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.