Dalian University participates in AnalySwift Academic Partner Program

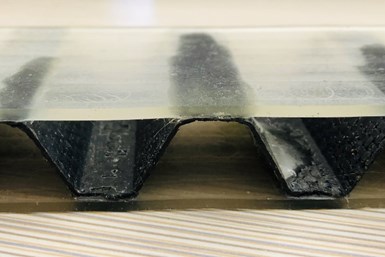

Dalian University of Technology uses Swiftcomp software to calculate the effective mechanical properties on morphing honeycomb and corrugated sandwich structures.

Photo Credit: AnalySwift

On Oct. 13 AnalySwift LLC (West Jordan, Utah, U.S.), a provider of efficient high-fidelity modeling software for composites, announced that Dalian University of Technology (Dalian, China) is participating in its Academic Partner Program (APP) launched in 2019, and it is using its SwiftComp and VABS simulation software for researching composite structures. The work is part of a project related to composite material structure design and processing technology under the direction of professor Shiyong Sun in the School of Mechanical Engineering at Dalian University of Technology. The research efforts are part of the Key Laboratory for Precision and Non-traditional Machining Technology of Ministry of Education, which focuses on mechanical manufacturing and automation, as well as mechanical engineering and instrument science and technology.

“SwiftComp and mechanics of structure genome (the theory on which SwiftComp is based) are used to calculate the effective mechanical properties of honeycomb structures and corrugated sandwich structures,” says Fei Gao, graduate student at Dalian University of Technology. “The research goal of the project takes the composite flexible morphing structure as the research object. Aiming at the requirements of large deformation, smoothness and continuous and high load-bearing of the morphing structure, the equivalent performance of the morphing structure based on the structural genome in SwiftComp is established from multiple levels such as equivalent performance modeling, morphing structure design, performance evaluation, design method application and optimal design of typical configurations under model and manufacturing constraints. Also, we will study the deformation coordination relationship between the flexible hyper-elastic skin and the substructure.”

According to Gao, the advantages of structure genome include highly accurate calculation results and high calculation efficiency, compared with other software or plugins used for calculating effective mechanical properties.

According to AnalySwift, its Academic Partner Program (APP) offers participating universities no-cost licenses of engineering software programs VABS and SwiftComp so students, researchers and faculty can leverage the tools in their academic research. It also affords students an additional avenue to highlight their research. A robust community of users helps answer questions through the online cdmHUB (composite design and manufacturing HUB) platform.

AnalySwift’s SwiftComp and VABS reportedly enable highly efficient, yet accurate modeling of composite structures and materials. SwiftComp, for instance, is a general-purpose multiscale modeling code that enables users to perform efficient and accurate modeling of composites. It provides unified modeling for various types of structures including 1D (beams), 2D (plates/shells), woven and 3D structures. The VABS program is a general-purpose cross-sectional analysis tool for computing beam properties and recovering 3D stresses and strains of slender composite structures. AnalySwift contends that it is a powerful tool for modeling composite helicopter and wind turbine rotor blades, as well as other slender composite structures, such as propellers, landing gear and high-aspect ratio wings.

“We are excited by the work being done by the Dalian University of Technology and pleased they have selected SwiftComp and VABS for their simulation of composite structures,” says Allan Wood, president and CEO of AnalySwift. “As versatile simulation tools for composites, they save orders of magnitude in computing time without a loss of accuracy so engineers can consider more design options and arrive at the best solution more quickly.”

“SwiftComp is a general-purpose, truly multiscale modeling code for composites. It directly and seamlessly links detailed microstructure and structural behavior for composite structures including beams, plates/shells and 3D structures,” comments Dr. Wenbin Yu, CTO of AnalySwift. “It can be used either independently as a tool for virtual testing of composites or as a plugin to power conventional finite element analysis [FEA] codes with high-fidelity multiscale modeling for composites. It saves hours in computing time and resources with accuracy comparable to modeling all the microstructural details using 3D FEA. SwiftComp quickly calculates the complete set of effective properties needed for use in macroscopic structural analysis. It can also predict accurate local stresses and strains in the microstructure for the purpose of predicting strengths, as well as thermal expansion of composites.”

Related Content

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreOptimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More