ÉireComposites, Wavefoil to produce retractable composite bow foils

Retractable composite bow foils for passenger ferries, fishing trawlers and yachts will lead to a more sustainable marine industry through a reduction in fuel consumption and reduced emissions.

Bow foils on M/S Teistin. All photo credit: ÉireComposites

Design, manufacturing and testing company ÉireComposites (Inverin, Galway, Ireland) announced on July 1 that it has signed a contract with Wavefoil (Tronheim), a Norwegian supplier of retractable bow foils, to manufacture composite foils for ships. The foils developed by ÉireComposites will be fitted onto passenger ferries, fishing trawlers and yachts, ranging in length between 100-200 meters; the Titanic, in comparison, was 269 meters.

Bow foils — also known as underwater wings — are nearly six meters in length, and are said to weigh more than two tons each. They use wave energy by generating thrust when the watercraft moves up and down in the waves, similar to a swimming whale. ÉireComposites says the bow foils concept has been a major innovation in the marine industry, but has never been commercialized successfully due to the lack of a retraction mechanism. This challenge, now addressed by its company through the use of composite materials, enables the development of foils that deliver fuel consumption savings, emissions reductions and motion damping of ships to improve the comfort on board for passengers.

“Composite materials underpin the overall structure of the foils and they enable the doubled-curved surfaces necessary to obtain a smooth and efficient foil geometry,” says Tomás Flanagan, ÉireComposites CEO. “They also introduce structural flexibility, which is essential when the foils exit the water in high waves and slam back into the water. The contract we’ve signed allows us to manufacture the tooling necessary, as well as the first set of foils, and will allow us to develop the most efficient design.”

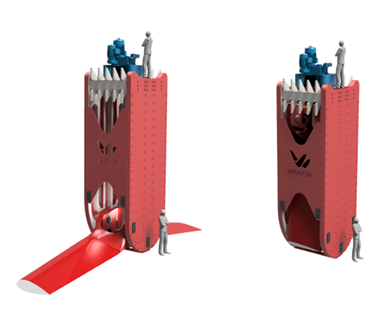

Illustration of Wavefoil's WF5910 retractable foil module.

The first developed foil module was retrofitted onto a vessel by Wavefoil in September 2019 and delivered an average fuel saving of approximately 8% during the first year of operation. Following the initial fitting, two smaller vessels have also been equipped with retractable bow foils. In 2020, Wavefoil secured funding to develop and test a prototype of a large foil module, which is said has the greatest fuel saving potential.

According to ÉireComposites, the contract with Wavefoil is an endorsement of the company’s expertise and knowledge in developing manufacturing tools that ensure the efficient production of foils on a large scale. Computational modeling of the foils, which will reportedly maximize efficiency, is performed by cDynamics (Kristiansand, Norway). ÉireComposites notes that the mold production for the foils has already commenced, and the first set of foils is expected to be delivered later this year with the foil module being assembled and tested in the final quarter of 2021.

“We look forward to seeing the foils take shape,” adds Chief Technical Officer Erlend Vastveit of Wavefoil. “This is certainly one of the most advanced composite structures ever, due to the extreme loads they need to handle. ÉireComposites has shown remarkable cooperation with Wavefoil so far and clearly contributed to the realization of our largest foil module.”

Related Content

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

-

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.