Éirecomposites and ORPC to use recycled carbon fiber in tidal turbine foils

Development part of €3M CRIMSON project to advance tidal energy for clean electricity.

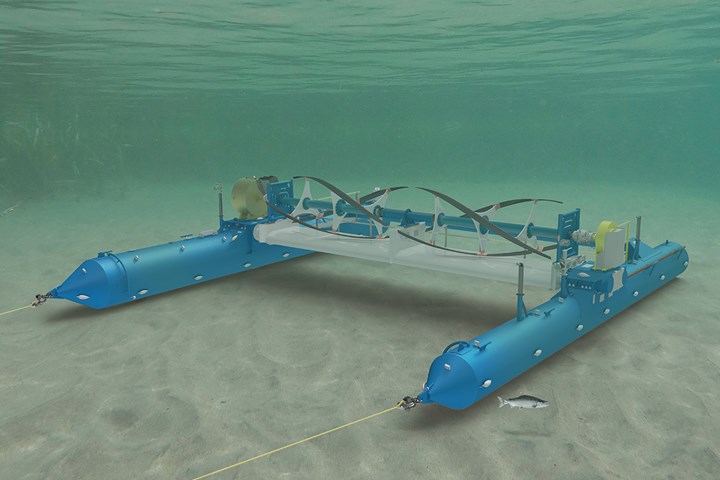

In 2014, ORPC built and operated its RivGen Power System for the remote Alaskan village of Igiugig. In 2015, it re-installed and operated an updated RivGen Power System in Igiugig to demonstrate its latest technology advancements, providing one-third of the community’s electricity needs and significantly offsetting their use of diesel fuel. Photo credit: ORPC

Leading Irish design, manufacturing and testing company, ÉireComposites (Inverin, Galway, Ireland), global marine renewable energy solutions company, ORPC (Portland, Maine, U.S.) and National University of Ireland Galway (NUI, Galway) have launched a new project to develop and market a state-of-the-art marine hydrokinetic (MHK) turbine based on ORPC’s proven, proprietary design. When in operation, this innovative MHK power system will produce clean energy at a reduced cost, while increasing reliability and performance of electricity output.

The CRIMSON (Commercialisation of a Recyclable and Innovative Manufacturing Solution for an Optimised Novel marine turbine) project has been funded by the European Commission as part of the Horizon 2020 Fast Track to Innovation (FTI) program. In the only Irish-led project to receive funding, ÉireComposites secured €3 million for this project and will lead the international consortium comprising ORPC (Ireland, Canada and U.S.), NUI Galway, Mitsubishi Chemical Advanced Materials (MCAM, Germany) and Consiglio Nazionale delle Ricerche (CNR, Italy). The total project is valued at €3.9 million.

The CRIMSON project plans to bring to market ORPC’s reliable, sustainable river and tidal turbine with foils made entirely of recycled carbon fiber, while also reducing capital expenditure and operating expenditure by 33% and 66%, respectively.

In the short term, the immediate impact of the adoption of this product into the market is that renewable marine energy will replace energy produced by fossil fuels. The longer-term impact of CRIMSON will demonstrate that this technology has the potential to generate gigawatts of clean energy from river and tidal currents. It is estimated that tidal streams, ocean currents, and riverine currents offer 615 terawatt-hours (1 trillion watt-hours) per year of harvestable energy and MHK power systems can harvest that.

The energy output of 615 terawatt-hours per year is estimated to be approximately 20 times Ireland’s annual electricity usage. Therefore, the impact is two-fold; first, to reduce manufacturing costs and, second, to significantly lower the environmental footprint of the materials employed in the turbine, leading to a more sustainable model of manufacturing within the sector.

This project furthers the partnership between ÉireComposites and ORPC, both of which have worked together to build previous iterations of ORPC’s turbines. In 2019, ORPC’s first commercial RivGen Power System was installed to power the remote community of Igiugig in Alaska, using sustainable, predictable local energy from the Kvichak River. The RivGen Power System offers a no-carbon, low-noise option, positively impacting local economies and enhancing ecotourism opportunities.

“At the conclusion of this project, we will have delivered a product that will have a positive impact on both the renewable energy sector and wider society,” says Tomas Flanagan, CEO of ÉireComposites. “There is no doubt that society is progressing towards greener communities and I believe CRIMSON will play a positive role in this transition in terms of driving down costs for both the industry and consumers but also increasing the productivity of the renewable energy sector.”

“Having worked with ÉireComposites and NUI Galway on previous and current Sustainable Energy Authority of Ireland (SEAI) projects, we look forward to working with them on developing our megawatt-scale turbine and we are confident in the team’s ability to achieve the ambitious targets laid out by the CRIMSON project,” says James Donegan, ORPC director of European operations. “ORPC has been growing operations in Ireland and Europe over the past several years and we see the technological advancements we will achieve with the CRIMSON project as crucial in commercializing our marine energy systems in the region.”

“It is through these types of collaborations that we have developed a world-leading laboratory for designing, modeling and testing tidal turbine blades,” says Professor Jamie Goggins at NUI Galway, which has reportedly applied the highest load to be reported onto a tidal turbine blade in 2020 and has one of the most advanced capabilities worldwide for designing and mechanically testing blades and foils for tidal and river current turbine technology.

The CRIMSON project is a continuation of previous research conducted by the Sustainable Energy Authority of Ireland (SEAI) and is supported by Údarás na Gaeltachta and Enterprise Ireland, who continue to assist the work undertaken by ÉireComposites.

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRead Next

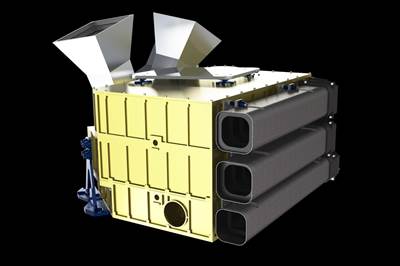

ÉireComposites to develop Ireland's first carbon fiber satellite optical instrument

Development and manufacture of three composite stray light baffles for the ESA’s ALTIUS satellite will assist in climate change research.

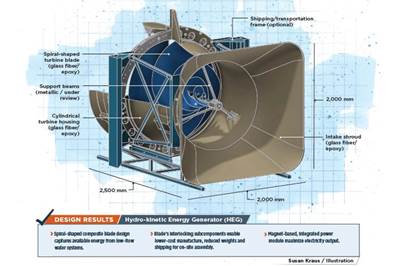

Read MoreHydroelectric turbine blade design propelled by composites

Glass fiber composites power the development of a modular, spiral-shaped hydroelectric micro turbine blade for low-cost, high-efficiency renewable energy generation.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More