European R&D project Bizente researches enzymatic technologies to recover thermosets

Through protein engineering, project partners molecularly modify enzymes and resins to make it possible to recover thermoset composites and give them a second life.

The EU project Bizente, coordinated by Aitiip Technology Centre (Zaragoza, Spain) and backed by almost €3 million in financing by the European Commission, continues to develop a biodegradation technology using enzymes that will enable the recyclability of thermoset composites, which are currently non-recyclable. The research, which has just completed 30 months, and in which a dozen European partners are collaborating, will make it possible to recover resins and other products at their end of life (EOL), with the aim of making them reusable and re-introducing them into the market.

Specifically, Bizente comes as an advanced, innovative and sustainable bioengineering solution that will help reduce the emission of non-biodegradable thermoset composite materials into the environment by 40%, avoiding their storage in landfills or incineration. Aviation, construction or wind energy industries may benefit from the Bizente model.

A recent study, led by the aviation consultancy Naveo (London, U.K.), predicted that aircraft decommissioning will increase in the coming years. In just one decade, it is estimated that at least 12,000 cargo or passenger aircraft will be scrapped, or 430,000 tonnes of composite waste. This figure does not yet include other types of aircraft, such as those used in the military. This horizon confirms to industry and society the need to optimize and develop new processes and technologies, not only for reusing and recycling, but also to adopt a more global approach, starting with the design of the aircraft itself, through more sustainable materials and manufacturing processes, aimed at providing a solution to the aircraft’s EOL.

The Bizente model was presented at Composiforum 2022 in November, an international forum for industry and research for present and future composite materials. Here, industry experts analyzed the growing circular trends in relation to these materials, and explained multiple applications that projects such as Bizente are currently promoting.

Project goals, current developments

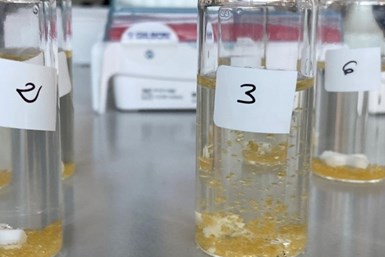

Thermoset testing.

Bizente’s technology aims to achieve a controlled biodegradation of thermoset composite materials through the use of enzymes. According to consortia members, these will be pre-engineered through directed evolution to adapt them to the degradation process. The reactions will be scaled up inside industrial chemical reactors. After this process, the resin monomers will be recovered, the by-products of the degradation process will be studied and their revalorization developed.

In the early stages of the project, partner EvoEnzyme (Madrid, Spain) successfully developed new enzyme technologies with the initial engineering of oxidoreductases and hydrolytic enzymes. With the guidance of structural analysis by partner Specific Polymers (Castries, France), the targeted evolution of selected biocatalysts is being followed and several variants have already been transferred to Biosphere for scale-up production. The bioengineering project is currently focusing on parallel pathways for the different types of materials, from which the most promising route for resin conversion will be selected.

Learn more about the Bizente project here.

Related Content

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Watch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.