Fast-FlexMont2 project targets optimized, large-structure CFRP assembly

Advanced measuring and referencing methods, highly precise positioning technologies and continuous digital process control by Fraunhofer IFAM demonstrate automated rudder hinge assembly.

Share

Read Next

Through the Fast-FlexMont2 (“Research on Agile Production Technologies

for CFRP Box Structures”) joint project funded by the German Federal Ministry of Economics and Climate Protection, Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM (Fraunhofer IFAM, Stade, Germany) experts from CFK NORD Research Center have recently presented an automated solution that makes it possible to optimize the production processes — automated assembly, including machining and joining — of large-scale structural carbon fiber-reinforced polymer (CFRP) parts. This was demonstrated via automated rudder hinge assembly for aircraft vertical tail planes (VTPs).

Individual manufacturing tolerances in the production of components and inaccuracies in the surface, contour and shaping that arise during the assembly of large CFRP components contradict the high-precision requirements in aviation, according to IFAM researchers. One way to compensate for this is to intentionally (and accurately) undersize individual components, then apply a “pasty” shim material (gap-filling material) to equalize the different gap dimensions between the joining partners due to tolerances. This procedure is used, among other things, in the production of aircraft VTPs boxes in the area of rudder hinge assembly.

Aiming to eliminate interruptions during the assembly of rudder hinges to the VTP box, researchers at Fraunhofer IFAM — in cooperation with Airbus Operations GmbH (Hamburg, Germany) and FFT Produktionssysteme GmbH (Hessen, Germany) — developed the application and outsourced curing of the shim material as parallel processes. In this context, automated and digitally linked processes enable volume-accurate dispensing and application, as well as precise shaping and edge finishing of the liquid shim. After curing the shim material, the finished shimmed rudder hinge is inserted into the VTP.

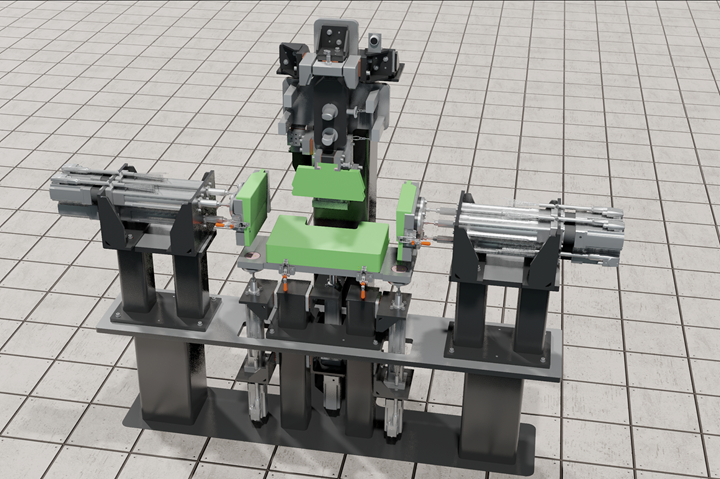

Virtual model within a digital twin: Outsourcing the curing process to an automated shim station. Photo Credit: Fraunhofer IFAM

Supported by digitization, automated process technologies not only enabled the application of shim material based on component variants and according to requirements, but also the outsourcing of the curing process in preparation for the assembly of components in the aircraft vertical stabilizer box. Lightweight, robotics-based assembly assistance systems are used to facilitate manual manufacturing processes while ensuring consistent quality. In addition to agile manufacturing, this optimization also achieves the reusability of technical resources through the parallelization of work steps, thus increasing productivity while reducing costs, according to researchers.

Based on the results of the Fast-FlexMont2 project, further manufacturing steps and their design with digitalized and automated sub-processes are being identified for optimization along the process chain, independent of individual branches. For example, the integration of digital marketplace structures for cross-company manufacturing is conceivable. Research will

focus not only on individual production activities, but also on considerably more complex component geometries.

Related Content

-

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.