German UniFix project develops mobile holding fixture to enhance production efficiency of large CFRP structures

Fraunhofer IFAM and Airbus Operations in Stade demonstrate reduced manual handling and non-productive time in flow-oriented manufacturing of vertical tail plane.

As part of the “UniFix” joint project — funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) — experts in Automation and Production Technology at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM, Stade), together with Airbus Operations GmbH (Stade) and other cooperation partners, have developed what is said to be a unique mobile holding fixture. This fixture is able to flexibly accommodate large components such as aircraft tail planes and landing flaps up to 8 meters long, and to align and transport them accurately and sustainably in terms of shape.

Focused on machining processes in the production sequence, this holding fixture is reportedly able to significantly reduce time-consuming, non-value-adding secondary activities in a follow-on machining system. This is achieved by first passing through various process stations with the optimally and precisely aligned large components, at which preparatory work can be carried out in parallel and simultaneously.

Transition to flow-line production

A milestone in the increasingly automated production, machining and assembly of large components made of carbon fiber-reinforced polymers (CFRP), the transition from manually pulsed production to flow-line production is currently imminent in aircraft production. As in other industries (such as automotive manufacturing), this flow-oriented production enables reduced throughput times and increased productivity,

efficiency and cost effectiveness. As a result, manufacturers are able to improve their competitiveness in the international market.

The advantages of flow-oriented manufacturing lie primarily in the reduction of manual handling operations and non-productive time. In addition, there are efficiency gains through specialization of the individual plants, harmonized cycle times and an associated decrease in buffer stocks and faster reaction to process deviations.

Challenges in the manufacturing of large CFRP structures

Both the vertical tail plane and the landing flaps of an aircraft are assembled from large flat shell elements stiffened by ribs. Before joining the shell elements, it is necessary to bring them to the required exact final contour by automated milling. Today, this machining process represents a bottleneck in production. It is also prone to risk, as errors at this high stage of the value chain can lead to considerable costs due to rejects or necessary correction of the component.

Flow-line production for CFRP aerostructures

“In order to significantly accelerate the process — while simultaneously minimizing risk — we decided in the UniFix project to implement mechanical machining in the manufacture of the vertical tail planes or landing flaps of a passenger aircraft as flow-line production,” Christoph Brillinger,

project manager from Fraunhofer IFAM, explains. “This allows us to avoid time-intensive secondary operations in the machining plant and thus significantly reduce its workload. At the same time, we meet the highest precision requirements in aircraft construction at all stations, which is a special challenge, especially with regard to the size and the production-related unique characteristics of the CFRP components. In Stade, we have developed a comprehensive referencing process which makes it possible to carry out measurement processes with regard to the component optimally positioned in the holding fixture independently of the machining station. At the machining station itself, only a quick referencing consisting of a few measuring points is then necessary.”

The stations of the flow-line

This versatile, mobile clamping device was developed by project partner FFT Produktionssysteme GmbH & Co. KG (Fulda). It can handle 10 different landing flap or vertical tail plane shell elements up to 8 meters long. Before it transports the large CFRP components to the machining system, it passes through two subsequent process stations. In the first station, the holding fixture is configured in an automated routine to pick up the respective component. Afterwards, a new type of multi-camera system (“camera arena”) from project partner Hexagon AICON ETALON GmbH (Braunschweig, part of Hexagon Manufacturing Intelligence) checks the shape accuracy. This ensures that the configured holding fixture optimally positions the CFRP component into the necessary target shape for the following precise machining. After that follows the insertion, positioning and clamping to secure the component.

For transport to the second station, the holding fixture, including the component, is connected to two automated guided vehicle (AGV) systems. These newly developed AGV systems from project partner Stäubli WFT GmbH (Sulzbach-Rosenberg) are capable of virtual coupling — which means they exchange data in order to be able to move synchronously without being mechanically connected to each other. This enables them to transport large

loads in synchronized operation through several vehicles in a coordinated manner.

Fraunhofer IFAM developed the second station, where the fixed CFRP component is measured with high precision and automatically using a laser line scanner. This measurement is essential because the component has a high shape variance — and therefore a unique character — due to the manufacturing process. The measurement data can be used to determine the

nominal machining paths and the nominal position of the hole positions for the component.

The component is now prepared for machining and can be moved from the mobile holding fixture to the machining system. The third station is the machining system. Since the conventional secondary activities of the

machining system have already taken place at the first two stations, only a quick referencing — consisting of the measurement of a few reference points — is necessary here before the actual machining task can be carried out immediately.

Application to other industries, follow-on project “InProNi”

The knowledge gained and technologies developed in the “UniFix” research project can not only be further advanced and implemented for aircraft production, but can also be transferred to the production processes of other industries — such as wind turbine, rail vehicle, commercial vehicle, automotive or shipbuilding — in order to increase efficiency.

In the “InProNi” (Innovative Production Systems from Lower Saxony) project funded by the state of Lower Saxony, Germany, which started on January 1, 2022, the concepts developed in the “UniFix” research project will be pursued further. The focus is on milling processes at the holding fixture in the machining plant as well as advanced referencing strategies.

Related Content

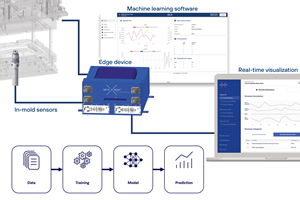

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Read MoreSAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.

Read MoreDLR develops safe, flexible workspaces for robot-assisted manual draping

The EU project Drapebot works on new ways of collaborating with industrial robots for manual CFRP preforming for large aircraft structural parts.

Read MoreNew Frontier Technologies launches digital twinning, high-fidelity simulation capability

3D imaging and analysis capability illustrates detailed, quality characterization and performance simulation of composites and other advanced materials that properly captures the as-manufactured component.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More