Frasle Mobility launches composites-focused brand Composs

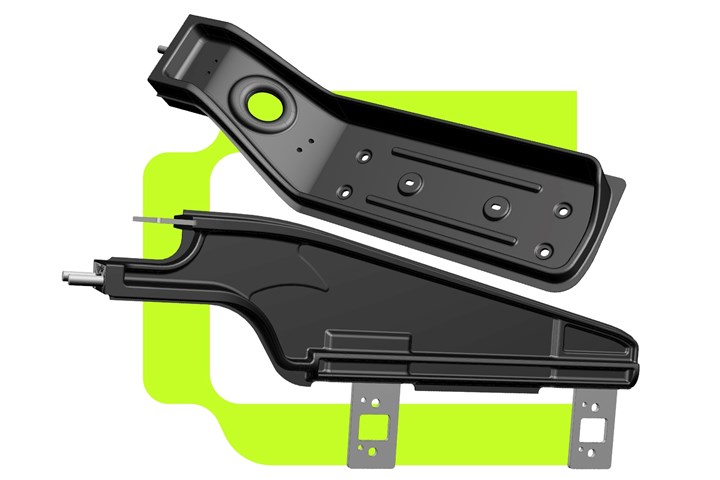

A production line in Brazil will produce composite automotive fender and tail light components for truck manufacturers.

Photo Credit: Composs

Sustainable mobility solutions company Frasle Mobility (Caxias do Sul, Brazil) announces the creation of a new composites-focused brand, Composs.

Presented to the market during the automotive event Automec 2023, Composs is an evolution of the company’s Smart Composites brand, which was launched in 2021 to enable new technologies focused on structural composites materials.

Composs’s first two products, highlighted at Automec 2023, are a fender support for road implements and fender and tail light support for trucks.

To produce fender and tail light supports, Frasle Mobility plans to add a new and largely automated line at its Caxias do Sul industrial complex in the third quarter of 2023.

Automaker Iveco, a brand of the Iveco Group, uses Composs’s components in its lines of heavy vehicles, with an exclusive, custom-made design for its truck models.

“The use of these components makes it possible to reduce the weight of the vehicle, providing fuel savings, increasing the strength and durability of the products. We are committed to constantly seeking new technologies and advanced solutions that meet our customers' needs while reducing our environmental impact. For Iveco, this partnership is another step towards that goal,” says Ricardo Coelho, Latin America product development director at Iveco.

Along with the advantages of using composites versus metals or other traditonal materials, Frasle Mobility says Composs’s manufacturing process is also less aggressive to the environment, and any raw material waste is sent to a partner to produce biosynthetic wood.

Frasle Mobility says the creation of Composs reflects the company’s efforts to consolidate its development of solutions for the automotive segment. The first research related to megatrends in the automotive industry and the use of composite materials began in 2018, through deep research investments in partnership with teams from the Hercílio Randon Institute (IHR) and the Randon Technological Center (CTR). The plan was shaped over the course of three years and in the first months of 2021 the adaptation and structuring of the industrial area began.

“We attest to this technology’s sucess, which can be customized for different automatkers and even for other market segments. This is the beginning of a new era for Frasle Mobility,” says Anderson Pontalti, superintendent director of Frasle Mobility and corporate leader of the Health, Safety and Environment department at Randon Companies.

Related Content

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

.jpg;width=70;height=70;mode=crop)