GKN Aerospace Future Flight Challenge to accelerate sustainable aerospace technologies

Four-year, £125 million ISCF program covers Skybus, Safe Flight and NAPKIN projects, with a focus on electrification, unmanned commercial flight and more sustainable regional aerospace solutions.

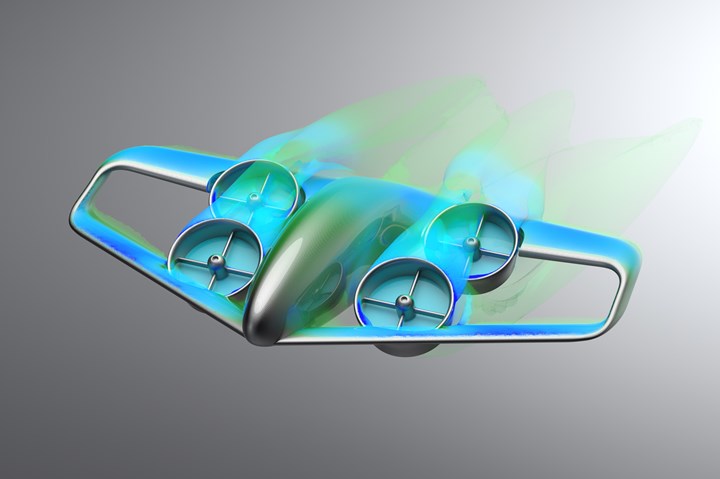

Photo Credit: GKN Aerospace

GKN Aerospace (Redditch, U.K.) is helping develop the next generation of sustainable technology through three ground-breaking collaborative programs as part of the Future Flight Challenge, a four-year, £125 million ISCF program from UK Research and Innovation to develop more sustainable aviation solutions and maintain the U.K.’s decarbonization targets. Taking a leading role in the programs, the company will be delivering them from its new £32 million Global Technology Center in Bristol.

“We’re investing in ambitious projects to make flying more sustainable and ensure passengers have greater choice about how they travel,” says Minister for Business Paul Scully. “Pioneering research supported by government funding will help the U.K. build back greener from the pandemic, remain at the forefront of aerospace research and development, and provide global leadership in the next aviation revolution. I look forward to seeing such proposals take flight.”

With 15 collaborators and an initial investment of £4.5 million, all three programs — Skybus, Safe Flight and NAPKIN — will focus on electrification, unmanned commercial flight and more sustainable regional aerospace solutions to drive connectivity; the current phase is specifically focused on the development of integrated aviation systems that enable new classes of electric or autonomous air vehicles.

Skybus explores a novel transport network, based on large electric vertical takeoff and landing (eVTOL) vehicles capable of carrying between 30-50 passengers each. Taking the “park and ride” concept into the air for mass transit over extremely congested routes, GKN Aerospace hopes to eliminate the 2D constraints of current surface transport modes including cars, trains and buses. It is said that this will offer direct benefits in reduced travel time at affordable fares, and reduce the congestion on current ground transport vehicles. Skybus is led by GKN Aerospace with the following partners: Swanson Aviation Consultancy, Pascall+Watson and Connected Places Catapult.

Safe Flight’s proposal addresses technological challenges, in terms of the integration of a range of cutting-edge technologies in real-world use case demonstrations. More importantly, says GKN Aerospace, this project also looks at the underpinning business need of a clear route to certifiable aircraft systems and approved operations. The following partners: University of Bath, 3UG Autonomous Systems and Callen-Lenz.

NAPKIN will model and pilot a U.K.-wide domestic sustainable aviation network promoting zero carbon emissions, connectivity where surface infrastructure is lacking, as well as U.K. business growth and competitiveness. NAPKIN is led by Heathrow Airport, in collaboration with GKN Aerospace, Rolls Royce, Highlands & Islands Airports, Deloitte, Cranfield Aerospace Solutions, London City Airport, University of Southampton, University College London and Cranfield University.

“We are committed to a more sustainable future for aviation and our technologies will keep us at the forefront of this challenge. No one company can achieve this alone and these Future Flight Challenge programs highlight the importance of collaboration in achieving this aim,” adds Max Brown, vice president Technology at GKN Aerospace. “It is a great example of public-private collaboration as well as the importance of government in supporting the aerospace industry, through it’s industrial strategy. We look forward to working together to deliver the next generation of sustainable air travel.”

Related Content

Composites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

U.K. companies join Team Tempest project to advance future air combat

Bombardier, GKN Aerospace, and more have signed agreements to progress design, manufacture and operation of the U.K.’s combat air system technologies.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More