Goodman Technologies, partners scale up AI-empowered 3D printing of nanocomposites for spacecraft TPS

NASA project addresses the capability gap in TPS production and installation for space exploration and hypersonic systems, delivering an ARMs system, nanopaste and prepreg tapes, manufacturing verification coupons and more.

Goodman Technologies LLC (Largo, Fla., U.S.), a rapid growth nanocomposite ecosystem platform company, with the University of Hawaii at Manoa Hawaiian Nano Laboratory (UHM-HNL) and the Wichita State University (WSU) National Institute of Aviation Research (NIAR), performed work under a NASA (Washington, D.C., U.S.) Phase II STTR that sought to explore the AI-empowered scale-up of additively manufactured continuous fiber ceramic nanocomposites (CFCNC) to revolutionize the manufacturing of thermal protection systems (TPS). These efforts addressed the critical capability gap in the production and installation of these advanced materials for NASA space vehicles and beyond that is affordable and non-labor intensive.

The advanced materials and manufacturing techniques developed in this project are expected to play a critical role in NASA’s Human Exploration and Operations Mission Directorate (HEOMD) Lunar and Mars missions, as well as the Science Mission Directorate (SMD) planetary missions, which require hypersonic entry through an atmosphere.

The overarching objectives of this project, spanning Phase I through Phase III, focused on:

- Manufacturing efficiency of TPS approaches: A comparative study of “top-down” and “bottoms-up” TPS approaches was conducted, with the aim of mitigating any disadvantages associated with each method. This dual approach ensured that the most efficient and effective manufacturing process was identified and implemented.

- Design of GTNANO automated robotic manufacturing system (ARMS): This system incorporates a range of advanced manufacturing techniques, including milling, fiber patch placement (FPP) of ceramic nanocomposite prepreg and the printing of ceramic nanopastes. The integration of these processes into a single automated system represents a significant advancement in the field of composites manufacturing.

- Development of nanopaste and prepreg tapes: Critical to the success of the project was the development of a low-shrinkage printable silicon carbide (SiC) nanopaste, as well as continuous roll-to-roll ceramic nanocomposite prepreg tapes. These materials are essential for producing a new category of high-quality continuous fiber ceramic nanocomposites (CFCNCs) with consistent properties.

- Production of a manufacturing verification coupon: Using the ARMS system, an 18-inch manufacturing verification coupon was produced. This coupon serves as a proof of concept, demonstrating the capabilities of the manufacturing process at scale.

During the past 4 years, the GT/UHM-HNL Team has multiple patent filings on the topics of SiC-based nanopastes which are 3D printable, moldable via a proprietary Z-process and have been used to make SiC (Hi-Nicalon)-reinforced prepreg for the molding, curing and joining of CFCNCs. CFCNCs are said to overcome the issue of delamination and segment separation, advancing the potential of spacecraft TPS and hypersonics in general.

GT’s TPS uses the 3D printable and moldable nanopaste for the shell and the Hi-Nicalon SiC/nanoSiC prepreg CFCNCs for the structural layer, which is bonded to a high-temperature CFOAM insulation core with a nanopaste adhesive. The process is amenable with other types of lightweight insulation. According to GT, the nano particulate used in the shell layer enables the system to have increased thermal conductivity, thermal stability and density. GT’s TPS is designed such that during entry through an atmosphere the outer shell will ablate and sublimate leaving the hot structure, which can then have a new shell 3D printed onto the surface for reuse. Arc-jet testing at NASA Ames Research Center proved that the hot structure was reusable. Notably, other printable ablation layers could be deposited on GT’s reusable hot structure.

The GT team was selected for a Phase II award where the automated manufacturing of the improved TPS was scaled up to about a half meter, though it is reported that there is really no limitation of scale for the process. To accomplish this, GT developed a large-scale ARMS which consisted of a six-axis robotic arm with the capability of swapping between a nanopaste extrusion end effector, milling attachment and FPP attachment. Alternately, multiple robots and cobots can perform the process.

Ultimately, FPP offers improved performance over the alternative of tape laying. The robotic arm places patches of material in a programmed pattern over the surface of the CFOAM core. Each patch was about 2 × 4 inches and was placed in such a way as to strengthen the areas of the TPS surface which GT has identified will be under higher levels of loading. The use of AI was pervasive throughout the process.

Partners note that each deliverable in this project represents “a quantum leap” in the field of composites manufacturing, particularly for spacecraft and hypersonic systems, including:

- The design of industrial large-scale printer/end effector: The development of a large-scale printer and end effector capable of handling the demands of ceramic nanocomposite materials is a critical step forward. This printer enables the production of large-scale components with the precision and consistency required for aerospace applications. Notable, the robotic arm introduces multiple degrees of freedom beyond the Cartesian and Polar coordinates systems that constrain 3D printers. Likewise, robots and cobots allow scaling of 3D printing beyond conventional build beds.

- Optimized low shrinkage printable SiC nanopaste: This nanopaste reportedly addresses one of the most significant challenges in additive manufacturing — material shrinkage. By optimizing the paste formulation, this project ensures that components maintain their intended dimensions and properties, even after processing.

- Design of scalable roll-to-roll ceramic nanocomposite prepreg: The development of a scalable roll-to-roll prepreg enables the continuous production of ceramic nanocomposite tapes. This capability is essential for manufacturing large components and structures, reducing costs and production times.

- Two-inch ceramic nanocomposite T300/n-SiC prepreg tape: This deliverable provides a practical and scalable material solution for aerospace applications. The 2-inch prepreg tape combines the strength of T300 carbon fibers with the thermal and mechanical properties of SiC, making it ideal for use in high-temperature environments.

- Four-inch bottoms-up and top-down TPS approaches: By refining the bottoms-up and top-down approaches to TPS, this project ensures that the most effective method can be selected based on specific mission requirements. These approaches offer flexibility in design and manufacturing, accommodating a wide range of applications.

- Eighteen-inch ARMS produced manufacturing verification coupon: The production of this coupon demonstrates the viability of the ARMS system for manufacturing large-scale components. This coupon will be subjected to rigorous testing to validate the material and manufacturing process.

Building on the success of this project, GT plans to participate in an investor-matched NASA Commercialization Readiness Pilot Program. This program will combine and test NASA’s 3D printable phenolic with GT’s reusable Hot Structure, with material validation at NASA Ames ArcJet facility. The ultimate goal is to manufacture a spaceflight test demonstrator using the ARMS system.

Moreover, the project has garnered interest from “New Space” companies in exploring GT’s CFCNC materials. These materials also offer retrofit opportunities for missiles, missile fairings, aeroshells and other strategic air platforms, particularly for hypersonic applications in Department of Defense (DOD) Programs of Record and System Primes.

Related Content

Demonstrating functionalized, cost-effective composites using additive extrusion

Hybrid thermoset/thermoplastic composite part with 3D-printed functionalization demonstrates technology possibilities and EmpowerAX open platform offering expertise from members throughout the process chain.

Read MoreHybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreRead Next

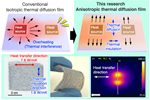

Nanocomposite films boost heat dissipation in thin electronics

Scientists from Japan develop cellulose nanofiber-carbon fiber composite films with high in-plane heat conductivity to assist in heat dissipation in electronic devices.

Read MoreArceon introduces novel CMC materials for space, defense

Carbeon C/C-SiC ceramic matrix composites are being developed and tested for rocket nozzles, onboard the International Space Station and in electric aviation, metal treatment and reactor applications.

Read MoreStratolaunch celebrates first powered flight of TA-1 test vehicle

Reusable hypersonic test aircraft met primary flight objectives and approached Mach 5 speed, gathering data for concurrent TA-2 and TA-3 test beds.

Read More