Henkel celebrates 100 years of its Adhesive Technologies business

The German company recognizes how far it has come since its founding, from development of laundry detergent packaging adhesives to today’s advanced solutions in more than 800 industry segments.

With the construction and startup of its own adhesives factory in Düsseldorf, Henkel began selling adhesive products on June 26, 1923. Photo Credit, all images: Henkel

Exactly 100 years ago, Henkel (Madison Heights, Mich., U.S. and Düsseldorf, Germany) began selling its first adhesive solutions to neighboring companies. From the development of laundry detergent packaging adhesives for its own use to today’s advanced solutions in more than 800 industry segments, the company’s adhesives, sealants and functional coatings are integral parts of countless consumer and industrial goods. In celebration of its century-long dedication to adhesives technologies, the company reminisces on its success story, sharing the visions of its customers and developing innovations in areas such as sustainability, mobility and digitalization.

“With our pioneering spirit and innovative strength, over the last 100 years, we have become the world’s largest manufacturer for adhesives, sealants and functional coatings, creating value for more than 100,000 industrial customers, as well as millions of consumers,” Mark Dorn, executive vice president of Henkel Adhesive Technologies, contends. “Our next step to create value across industries around the world is to develop the sustainable solutions necessary that enable circularity and CO2 reduction. Then. as now, we collaborate with our customers to turn challenges into opportunities and to innovate products and solutions.”

Today, the central focus of Adhesive Technologies’ innovation activities is on developing sustainable solutions for its customers.

The success story of Henkel Adhesive Technologies began 100 years ago. After the end of the WW1, the occupation of the Rhine and Ruhr threatened to cause a shortage of adhesives at the company’s home base in Düsseldorf, Germany, which were needed to seal Henkel’s own product packaging for detergents. As a result, in 1922, Henkel started to develop and produce paper, cardboard and packaging adhesives for its own use. With the construction and startup of its own adhesives factory, the company also began selling adhesive products to neighboring companies on June 26, 1923. First products included the painter’s glue Mala and the wallpaper paste Tapa, both based on potato flour.

Since its start, Henkel says its Adhesives Technologies business has globally pioneered through patented inventions, innovation power and strategic acquisitions. Inventions, for example, include the Pritt glue stick in 1969, which took inspiration from the twist mechanism of lipstick and revolutionized papercrafts for more than 50 years. In 2001, Pritt was given a “Space-Proof” seal of quality and was sent to the International Space Station (ISS).

The central focus of Adhesive Technologies’ innovation activities today is on developing sustainable solutions for its customers.

In the industrial sector, adhesive solutions from Henkel have transformed production processes and product designs in automotive, electronics, packaging and more. The technologies provide tailored functionalities that include strong bond, sealing, coating, conductivity of heat and electricity, recyclability and many more. With the acquisition of the Loctite Corp. in 1997, Adhesive Technologies successfully integrated capabilities to move the business to a new level.

Henkel has demonstrated the diverse performance capabilities of its solutions in many ways over the past 100 years. In 1987, for example, Ceresit products were used in the renovation of the Great Wall of China. And in 2015, Henkel developed a customized adhesive to professionally reattach the broken-off beard of Tutankhamun’s famous death mask (watch this video with highlights and milestones from 100 years of Henkel Adhesive Technologies).

“We are proud of our success story of 100 years at Henkel Adhesive Technologies,” Dorn says. “A look at the last 100 years shows the continuous development of our technological know-how and market expertise. With this strong history of innovation and remarkable achievements behind us, we look forward to a bright future where Adhesive Technologies continues to make history and create the solutions of tomorrow.”

The central focus of Adhesive Technologies’ innovation activities today is on developing sustainable solutions for its customers. The business unit is consistently working on products that enable resource efficiency in production and during use throughout the entire lifecycle and that are based on renewable or recycled raw materials. In addition, Henkel offers a growing portfolio for the recyclability of, for example, packaging or consumer goods and the repairability of everyday products.

To take its innovation capabilities to the next level, Adhesive Technologies opened its Inspiration Center Düsseldorf at its home site in 2022. In this modern innovation center with more than 30 laboratories, more than 650 Henkel experts work on highly effective and sustainable solutions in adhesives, sealants and functional coatings. At the same time, the state-of-the-art building serves as a global customer center where Adhesive Technologies presents its entire technology portfolio and strengthens collaboration with its customers from more than 800 industry segments. In 2023, the business unit will gradually open another global innovation center in Shanghai.

Related Content

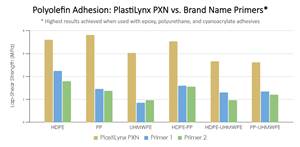

XlynX’s PlastiLynx PXN crosslinking primer enhances polymer adhesion

PFAS-free diazirine primer makes surfaces receptive to all manner of adhesives, including epoxies and polyurethanes, outperforming alternative options by 150-350%.

Read MoreBelzona composite wrap restores corroded carbon steel pipeline

Two-part epoxy paste, epoxy structural adhesive, composite wrap and anti-corrosion coating prevent environmental and economic loss for customer.

Read MoreHeat-activated foaming core rapidly achieves net-shape 3D parts

CAMX 2024: L&L Products exhibits its InsituCore foaming core structural technology, which can be used to create foam core composites minus machining or presses, as well as the Phaster A K-700, a rapid-cure adhesive.

Read MoreSyensqo introduces AeroPaste 1003 aerospace adhesive

Two-part room-temperature paste increases high-rate assembly and joining efficiencies when bonding metallic and composite parts.

Read MoreRead Next

Scott Bader to celebrates 100 years as a company, 70 years employee-owned

Global manufacturer of adhesives, resins, gelcoats and functional polymers reaches company milestone, organizes a range of celebrations to recognize the company’s journey.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More