INCA Renewtech to build advanced biocomposites manufacturing facility in Alberta, Canada

The fiber processing and composites manufacturing facility will ramp up INCA’s production of highly refined short and long fibers to substitute increasingly scarce balsa wood in boats, wind turbine blades, rail and automotive.

Share

Read Next

INCA BioBalsa in wind turbines. Photo Credit, all images: INCA Renewable Technologies

In a win for Alberta, Canada’s cleantech sector and rural job creation, INCA Renewable Technologies (Kelowna, Canada) has announced plans to build a state-of-the art, 200,000-square-foot fiber processing and composites manufacturing facility in Vegreville, Alberta. The chosen location is adjacent to InnoTech Alberta, the Government of Alberta’s premier research facility for hemp composites, genomics and agronomics. The INCA factory is expected to be operational in early 2024 and create 70 jobs, scaling to about 100 jobs by 2026.

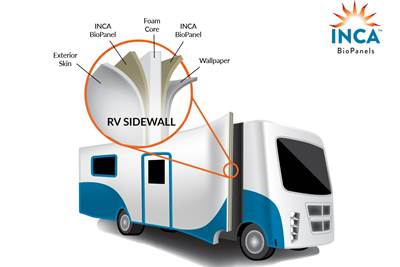

“When ramped to capacity, INCA’s operation will purchase 54,000 tonnes of biomass per year generated from farmers growing hemp for plant-based protein. We will process this renewable resource into highly refined fiber,” David Saltman, chairman and CEO, INCA, notes. “The short fiber will be transformed into INCA BioBalsa, a direct substitute for the balsa wood used as an essential core material in the construction of boats and wind turbine blades. The long fiber will be sent via rail to our second factory in Bristol, Indiana, where we will manufacture BioPanels for the RV industry and BioPlastics for the automotive industry. Winnebago [Forest City, Iowa, U.S.] and Toyota [Plano, Texas, U are commercialization partners for these products.”

According to INCA, the demand for balsa wood, particularly for wind turbine blades, has led to deforestation in Ecuador where it is a native species. Plantations now account for 60% of supply but quality is falling, prices are rising and manufacturers are seeking viable alternatives.

An independent lifecycle report conducted by GreenStep Solutions (Kelowna), which has helped more than 3,000 organizations better understand the environmental impact of their operations, demonstrated that INCA’s hemp-based BioBalsa is far more sustainable than balsa wood. One cubic meter of BioBalsa reportedly sequesters 260 kilograms (approx. 573 pounds) of CO2. During the manufacturing process, BioBalsa also generates 107% less greenhouse gas emissions than cutting and milling balsa wood, the report found, reduces waste generation by 93% and water consumption by 93%. As a result of its compressive strength, sustainability and moisture and fire resistance, BioBals offers users improved performance.

“We have helped over 3,000 businesses and corporations measure and reduce their environmental impacts through independent energy, waste, carbon and lifecycle analysis,” Angela Nagy, president and CEO, GreenStep Solutions Inc., points out. “The lifecycle report we conducted for INCA Renewtech took into account the environmental impacts of extraction, production, resource use and end-of-life [EOL] disposal. Our report concluded that all of the INCA products assessed dramatically reduced carbon emissions and environmental impacts, when compared to competitive products made of petroleum, wood or fiberglass.”

INCA’s choice to locate in Alberta shines a spotlight on the province’s growing cleantech and agri-tech sectors, joining the growing list of green energy-related announcements in Alberta from PACE, Cvictus, Air Products and more. INCA chose Alberta in part thanks to the provincial government’s investments over the past 20 years to develop a thriving hemp supercluster and research capability. Alberta is now said to be a global leader in the production of sustainably grown hemp and responsible for 40% of Canada’s hemp production. INCA’s purchase of waste hemp fiber from local farmers will make hemp a dual use cultivar and one of the most valuable cash crops in the Prairies.

Invest Alberta is supporting INCA’s investment journey in Alberta by connecting the company to potential investors, strategic partners, grant sources and researchers, as well as providing export guidance.

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

3A Composites Core Materials commits to sustainable growth, harvesting and processing of balsa wood

The core materials company has signed a two-year technical agreement with the nonprofit Achuar Nationality of Ecuador to achieve enduring development of indigenous communities and responsible forestry.

Read MoreStudy reports INCA Renewtech hemp-based biocomposites radically reduce carbon emissions

Compared to lauan rainforest plywood, INCA’s BioPanels are reported to reduce carbon emissions, waste production and water consumption.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More