Leonardo, Vertical Aerospace to jointly develop VX4 eVTOL carbon fiber fuselage

Leonardo lends its composite aerostructures expertise, honed on numerous civil and defense aerospace programs, for initial six certification aircraft.

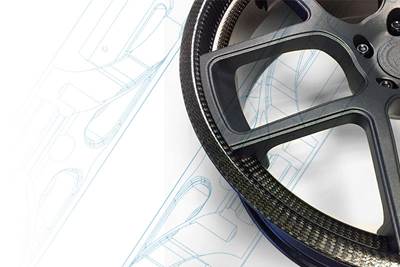

Photo Credit: Vertical Aerospace

Vertical Aerospace (Bristol, U.K.) an aerospace and technology company pioneering zero-emissions aviation, has agreed to a joint development program with Leonardo (Rome, Italy) for the design, testing, manufacture and supply of the carbon fiber composite fuselage for Vertical’s VX4 electric aircraft.

The VX4 is a near-silent, entirely electric, piloted aircraft that is expected to have a range of more than 100 miles and to reach top speeds of up to 200 miles per hour. With a four-passenger capacity, Vertical says the zero-operating emissions VX4 will also have a low cost-per-passenger mile, similar to that of a taxi.

Vertical and Leonardo will work together on optimizing lightweight composite structures, modular design, systems installation and structural testing for the co-development of the aircraft’s fuselage. According to Vertical this is currently in place for at least six certification aircraft, up to the successful certification of the VX4.

The agreement has also stated the potential to scale fuselage production to 2,000 aircraft per year to meet Vertical’s existing order book demand. Vertical has what it believes is the largest conditional pre-order book (by value) in the electric vertical takeoff and landing (eVTOL) industry, with up to 1,350 aircraft worth $5.4 billion from American Airlines, Avolon, Bristow and Iberojet, including pre-order options from Virgin Atlantic and Marubeni, and through Avolon’s JAL and Gol airline placements (see “Vertical Aerospace secures funding for zero-emissions eVTOL aircraft”).

Leonardo has long-established expertise in composite aerostructures development and manufacturing on civil and defense programs. The aerospace firm also has a close relationship with Vertical’s strategic composite materials supplier, Solvay (Alpharetta, Ga., U.S.). Vertical and Solvay are jointly developing advanced materials and manufacturing technologies that will enable high-volume manufacture of the VX4.

“Leonardo, as partner to the world’s leading commercial aircraft manufacturers, specializes in the production and assembly of major structural composite and metallic components for commercial aircraft,” emphasizes Giancarlo Schisano, managing director of Leonardo’s Aerostructures Division. “Leonardo strives to bring new technologies, materials and processes into our established practices in our production sites. This will be the case at our Grottaglie plant in southern Italy, where we will focus our VX4 activities; the plant is one of the most advanced facilities in Europe to produce composite aerostructures.”

Moreover, the continuous development and integration of cutting-edge solutions across all domains, such as advanced air mobility (AAM), is also a key element of Leonardo’s BeTomorrow2030 Strategic Plan.

Vertical’s partnership with Leonardo builds on an ecosystem of partners, including Rolls-Royce (London, U.K.), Honeywell Aerospace (Los Angeles, Calif., U.S.), Solvay, GKN Aerospace (Redditch, U.K., see “Vertical Aerospace partners with GKN Aerospace on wing structure for VA-X4 eVTOL”) and Microsoft (Redmont, Wash., U.S.). Vertical continues to grow its team of experienced engineers and aviation executives and expects to begin the VX4’s test flight program later in 2022.

“Vertical is pioneering electric aviation and is on a mission to transform the way people travel. I have been impressed by Leonardo’s highly innovative and industry-leading technical and manufacturing capabilities and our partnership has got off to a flying start,” adds Michael Cervenka, president of Vertical Aerospace. “I’m thrilled that Leonardo will be joining us in this journey. We have a market-leading pre-order book for our VX4, and this partnership will ensure that we can scale the program to meet demand.”

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

Carbon ThreeSixty, Leonardo, NCC all-composite helicopter wheel project takes off

The 18-month project will design, develop and manufacture 12 fully tested ultra-low mass, robust, proof-of-concept CFRP wheels for rotary wing aircraft.

Read MoreClean Sky 2 FUSINBUL project develops full-scale, carbon fiber pressure bulkheads

Two 3.5-meter pressure bulkhead demonstrators incorporate advanced layup techniques with the goal of increasing serial production capabilities for fuselage manufacture for regional aircraft.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More