LivMatS biomimetic flax fiber Pavilion opens to the public

Made entirely of filament-wound flax fiber, the livMatS Pavilion combines integrative design, robotic fabrication and sustainable materials for a highly innovative, bio-inspired construction.

LivMatS Pavilion. All images, photo credit: Institute for Computational Design and Construction, Institute of Building Structures and Structural Design, University of Stuttgart.

Completed and open to the public, the livMatS Pavilion, a biomimetic structure located in the Botanical Garden of the University of Freiburg (Germany), is said to offer a viable, resource-efficient alternative to conventional construction methods and therefore represents an important step towards sustainability in architecture. Further, it constitute what its project team claims is the first building with a load-bearing structure that is entirely made of robotically wound flax fiber, a naturally renewable, biodegradable, and regionally available material in Central Europe.

Enabled by a novel combination of natural materials and advanced digital technologies, this pavilion stems from the successful collaboration of an interdisciplinary team of architects and engineers of the ITECH master’s program at the Cluster of Excellence “Integrative Computational Design and Construction for Architecture (IntCDC)” at the University of Stuttgart (Germany) and biologists from the Cluster of Excellence “Living, Adaptive and Energy-autonomous Material Systems (livMatS)” at the University of Freiburg (Germany).

Woven flax fibers.

According to the team, the bio-inspired pavilion showcases how novel co-design processes that account concurrently for geometrical, material, structural, productional, environmental and aesthetic requirements, together with advanced robotic fabrication techniques applied to natural materials, are capable to generate an architecture that is, at the same time, ecological and expressive. The distinctive, intricate surface appearance of the structural flax elements is evocative of both vernacular examples of latticework and biological systems.

For the next five years, the livMatS Pavilion will serve as an outdoor lecture room at the University of Freiburg, especially for those at at the University of Freiburg, which use the Botanic Garden within the concept of “learning from nature in nature” as a research and teaching site. Scientists will also present their work there to the public in guided tours or workshops.

Natural fiber materials, biomimetics

Over the past two years, a team of architects and engineers at the Institute for Computational Design and Construction (ICD) and the Institute of Building Structures and Structural Design (ITKE), University of Stuttgart, have investigated the potential of using natural fibers as a building material, believing they present a promising and sustainable alternative to synthetically produced fibers. They have found with the livMatS pavilion that, in addition to offering the potential to reduce the environmental footprint of the building and providing a renewable material for the construction industry, the flax fibers are comparable in their mechanical properties to glass fiber rovings, providing similar stiffness per weight, but with a much lower embodied energy.

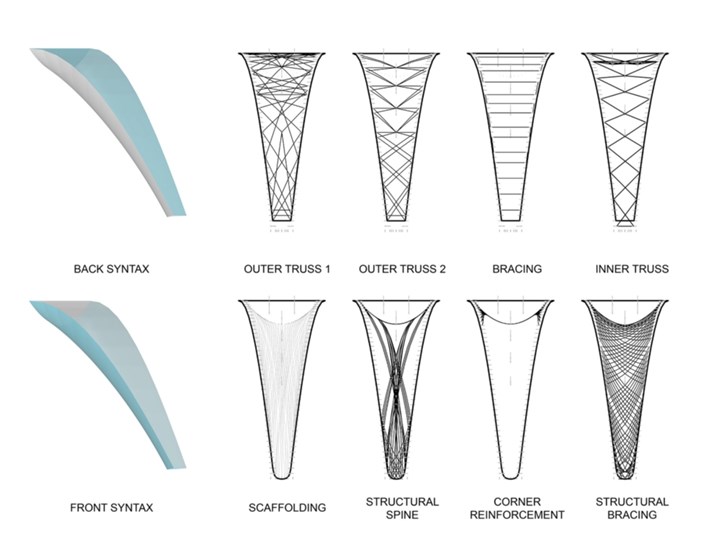

Generative design of the Pavilion.

Further, the structure continues the long-standing research collaboration to determine how biology’s principals — such as load-bearing systems — can be transferred from nature into architecture. The livMatS pavilion was inspired by the saguaro cactus (Carnegia gigantea) and the prickly pear cactus (Opuntia sp.), which are characterized by their wood structure. The saguaro cactus has a cylindrical wooden core that is hollow inside and thus particularly light. It consists of a net-like wooden structure, which gives the skeleton additional stability and is formed as a result of the intergrowth of its individual wood elements. The tissue of the flattened side shoots of the prickly pear cactus is also interwoven with net-like wood fiber bundles, which are arranged in layers and interconnected. As a result, the tissue of the prickly pear cactus is characterized by a particularly high load-bearing capacity. By abstracting these network structures, the scientists were able to transfer the mechanical properties of the cross-linked fiber structures to the lightweight structural elements of the pavilion.

Integrative design and fabrication

The project expands on more than 10 years of research in fiber construction. Previous research focused on the use of synthetically produced fiber composites in construction, such as glass and carbon fibers, in combination with advanced computational design, simulation and fabrication methods. The livMatS pavilion extends this research towards a more sustainable method of construction with natural flax fibers and investigates the use of these natural fibers in a large-scale application.

A robot precisely places fiber bundles on a winding frame.

The load-bearing building elements are produced with a core-less filament winding process developed by the project team. In this additive manufacturing (AM) approach, a robot precisely places fiber bundles on a winding frame. This reportedly allows for the targeted calibration and architectural articulation of the orientation, alignment and density of the fibers to exactly fit the structural requirements in the component, as in its biological inspiration. According to researchers, pre-defined component shape only emerges through the interaction of the fibers within the winding frame, eliminating the need for an additional mold or core. In addition, this fabrication method does not produce any waste or offcuts. Moreover, the same modular winding frame can be used for all geometrically varying elements. This leads to an excellent material efficiency when measured against conventional building materials and results in a high load-bearing capacity.

Natural fibers and their biological variability have also presented the researchers with new challenges, particularly with regard to the computational design and robotic fabrication workflows, as well as to the machine control. These co-design workflows were initially developed for synthetic and thus homogeneous materials and now required to be adapted to the material properties of flax fibers. This adjustment of the integrative computational design model enabled the heterogeneous material properties to inform the design and planning of the individual components as well the overall structure. The specific mechanical properties of the natural fibers also required the reconfiguration of the robotic fabrication process.

The livMatS pavilion is covered with a waterproof polycarbonate skin, which not only provides weather shelter but also protects the fibers from direct UV radiation, and moisture from rain or snow.

Integrated demonstrator for sustainable construction

The load-bearing structure of the livMatS pavilion consists of 15 flax fiber components, robotically prefabricated exclusively from continuous spun natural fibers, as well as a fibrous capstone element on top of the structure. The elements vary in overall length from 4.50 to 5.50 meters and weigh only 105 kilograms on average. The entire fiber structure weighs approximately 1.5 tons while covering an area of 46 square meters. The final design complies with the German building code and related structural permit requirements and set of load combinations including wind and snow loads.

The research developments relating to the computational process, the robotic fabrication as well as the new material system was developed by an interdisciplinary team of ITECH students and ICD/ITKE researchers at the University of Stuttgart and was validated by the fabrication of a first series of prototypes of the natural fiber components. The production data was then generated and passed to the project’s industrial partner FibR GmbH (Stuttgart, Germany) for the production of the 15 structural components.

The project continues a series of successful experimental and highly innovative building demonstrators designed and realized by the interdisciplinary team of researchers and students at ICD/ITKE University of Stuttgart. It also further strengthens the already successful collaboration between the Cluster of Excellence livMatS at the University of Freiburg and the Cluster of Excellence IntCDC at the University of Stuttgart. IntCDC aims to rethink design and construction through digital technologies to address the ecological, economic and sociocultural challenges the built environment is facing. The vision of livMatS is to combine nature and technology to develop cutting-edge environmental and energy technologies. By its very nature, the pavilion offers points of contact to highlight similarities and differences between biological and technical materials and to show the possibilities that bioinspiration offers, for example in architecture but also in other areas of technology.

Scientific development:

- Marta Gil Pérez, Serban Bodea, Niccolò Dambrosio, Bas Rongen, Christoph Zechmeister

- Project Management: Katja Rinderspacher, Marta Gil Pérez, Monika Göbel

Concept development, system development, prototyping:

- 2018-2020: Talal Ammouri, Vanessa Costalonga Martins, Sacha Joseph Cutajar, Edith Anahi Gonzalez San Martin, Yanan Guo, James Hayward, Silvana Herrera, Jeongwoo Jang, Nicolas Kubail Kalousdian, Simon Jacob Lut, Eda Özdemir, Gabriel Rihaczek, Anke Kristina Schramm, Lasath Ryan Siriwardena, Vaia Tsiokou, Christo van der Hoven, Shu Chuan Yao

- 2018-2019: Karen Andrea Antorveza Paez, Okan Basnak, Guillaume Caussarieu, Zhetao Dong, Kurt Drachenberg, Roxana Firorella Guillen Hurtado, Ridvan Kahraman, Dilara Karademir, Laura Kiesewetter, Grzegorz Łochnicki, Francesco Milano, Yue Qi, Hooman Salyani, Nasim Sehat, Tim Stark, Zi Jie, Jake Tan, Irina Voineag

Facade development:

- Tim Stark

- With support of: Okan Basnak, Yanan Guo, Axel Körner

- Student assistance: Matthew Johnson, Daniel Locatelli, Francesca Maisto, Mahdieh Hadian Rasanani, Lorin Samija, Anand Shah, Lena Strobel, Max Zorn

Related Content

3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read More3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

Read MoreRead Next

Natural fiber composites: What’s holding them back?

Natural fiber reinforcements have been available for some time, but factors such as compatibility with current processes and geographic availability continue to limit widespread use.

Read MoreSolution-based digital composites fabrication

MIT evolves liquid biomaterials into a new approach for sustainable engineered composite structures.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More