Magnum Venus Products to expand capacity in Tennessee

MVP will spend $20 million over five years to build a new 125,000-square-foot manufacturing facility in East Tennessee.

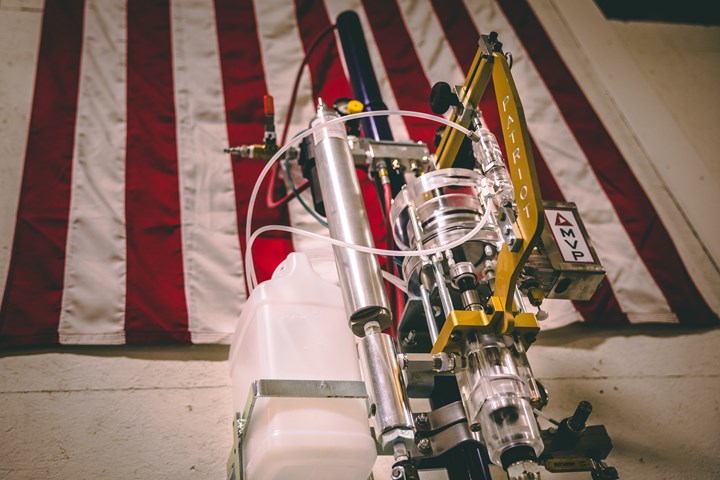

Photo Credit: MVP

Magnum Venus Products (MVP, Knoxville, Tenn., U.S.), a global manufacturer of fluid movement and production solutions for composites manufacturing, reported on April 11 that it is expanding its footprint and capabilities with the purchase of a facility and land in East Tennessee. The expansion, says MVP, will enable the company to increase its manufacturing velocity and meet customer demand.

The expected $20 million investment over five years includes 17 acres of land and a 125,000-square-foot facility. The new location will combine MVP’s corporate office and its Knoxville assembly and service center into one site and create a foundation for continued growth. The renovated facility is expected to generate 100 jobs over the next five years in East Tennessee.

“While we operate a number of facilities throughout the United States, East Tennessee has been our home for over a decade,” says Tobi Ferguson, president and CEO of MVP. “The composites and advanced manufacturing resources available here present unique business opportunities to catalyze continued growth for MVP. And with 40% of our customers located East of the Mississippi River, Knoxville is geographically ideal.”

Currently, MVP operates a headquarters in Knoxville and a 75,000-square foot manufacturing and technology center in Kent, Wash., U.S., which employs approximately 100 people. While the Kent facility will continue to operate, the additional capacity in East Tennessee will dramatically increase production rates, driving down lead times and enabling improved service performance to customers.

“At its core, MVP is a family-owned business with a proud history of innovation,” says Ferguson. “MVP was built by a caring, people-first team on values that continue to guide it today. Our growth and success can be attributed to an inspired team with a passion for serving others.”

MVP’s mixing and metering composite equipment includes pumping systems, spray guns, filament winding systems and other full-integrated production solutions.

Related Content

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

.jpg;maxWidth=300;quality=90)