Metyx multiaxial glass fiber fabrics gain GFRP drinking water pipe approval

Metyx non-crimp fabrics earned accreditation for GFRP drinking water pipes and potable water storage systems through independent testing, as well as certifications for marine and wind energy composites applications.

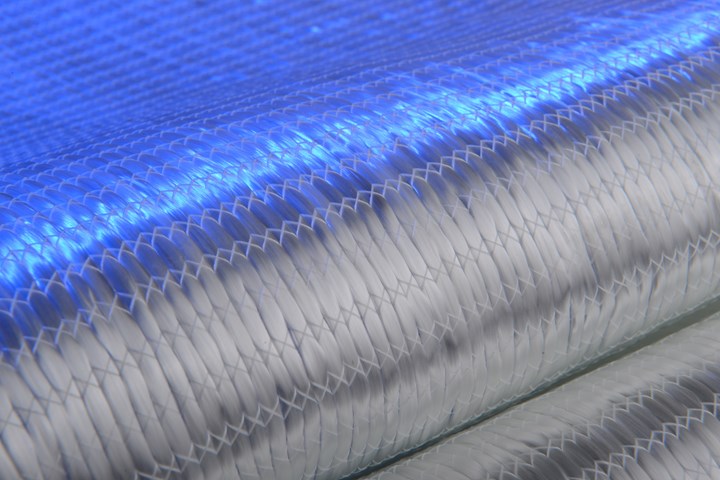

Close-up of multiaxial glass fiber fabrics. Photo Credit: Metyx Composites

The Metyx Composites (Istanbul, Turkey) range of multiaxial glass fiber fabrics has recently gained accreditation for being safe to use in the manufacture of unsaturated polyester, vinyl ester and epoxy resin glass fiber-reinforced (GFRP) drinking water pipes and GFRP potable water storage systems.

Metyx’s multiaxial glass fiber fabrics were independently tested according to the migration standard XP P 41-250-2 by CARSO-Laboratoire Santé Environnement Hygiène de Lyon — a France-based group that provides water analysis as part of the wide range of analytical services carried out by its European network of specialist laboratories — and are now certified for use in the reinforcement of materials in contact with drinking water according to circular DGS/SD7A/2006/370.

Multiaxial glass fiber fabrics, also known as non-crimp fabrics (NCF), are made up of one or more layers of unidirectional (UD) glass fibers stitched together. This type of GFRP reinforcement is well established for the manufacture of water, drainage and sewage pipes.

“The addition of this new drinking water pipe approval has extended the reinforcement product offering that Metyx is now able to supply to both new customers and our existing GFRP pipe producers,” says Bahattin Sendogan, Metyx European sales director.

Along with this latest product approval, Metyx has also been awarded DNV GL and Lloyds Register certifications for marine and wind energy composites applications. All Metyx technical textile products are manufactured according to TUV Nord- and SGS-certified ISO 9001 Quality, ISO 14001 Environmental and ISO 45001 Occupational Health and Safety Management Systems standards.

Metyx Group offers a complete range of RTM, multiaxial and woven technical fabrics, kitting of cores, fabrics, preforms and vacuum consumables, plus tooling, consultancy engineering, design and testing services.

Related Content

-

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

-

Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.