NASA announces new James Webb Space Telescope target launch date

The observatory is expected to launch Oct. 31, 2021, a change resulting from technical challenges and the impact of the pandemic.

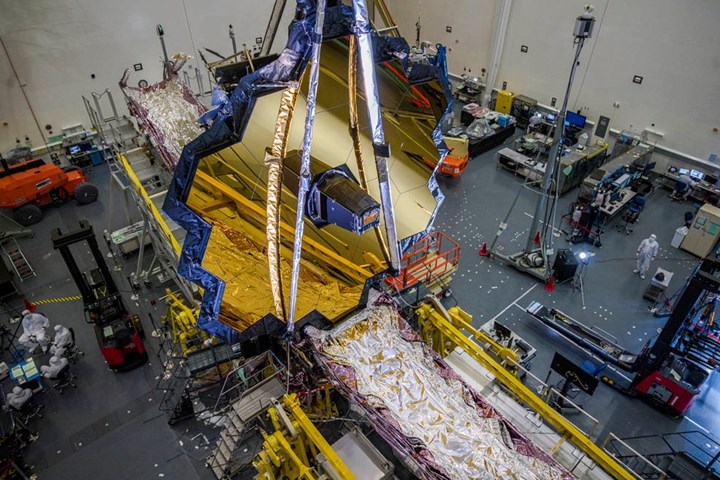

NASA's James Webb Space Telescope in the clean room at Northrop Grumman, Redondo Beach, Calif., U.S., in July 2020. Source | NASA/Chris Gunn

According to NASA’s recent report, the James Webb Space Telescope, a complex observatory that will detect infrared light and study the atmospheres of nearby exoplanets for possible signs of habitability (read “NASA assembles James Webb Telescope”) is now targeted to launch Oct. 31, 2021 due to impacts from the ongoing coronavirus pandemic, as well as technical challenges. This decision, says NASA, is based on a recently completed schedule risk assessment of the remaining integration and test activities prior to launch. Previously, Webb was targeted to launch in March 2021.

“The perseverance and innovation of the entire Webb Telescope team has enabled us to work through challenging situations we could not have foreseen on our path to launch this mission,” says Thomas Zurbuchen, associate administrator for NASA’s Science Mission Directorate at the agency’s headquarters in Washington D.C., U.S. “Webb is the world’s most complex space observatory, and our top science priority, and we’ve worked hard to keep progress moving during the pandemic. The team continues to focus on reaching milestones and arriving at the technical solutions that will see us through to this new launch date next year.”

NASA notes that testing of the observatory continues to go well at Northrop Grumman, the mission’s main industry partner, in Redondo Beach, Calif., U.S. despite the challenges of the coronavirus pandemic. Prior to the pandemic’s associated delays, the agency says the team made significant progress in achieving important milestones to prepare for launch in 2021.

As schedule margins grew tighter last fall, the agency planned to assess the progress of the project in April. This assessment was postponed due to the pandemic and was completed the week of July 13. NASA points to factors contributing to the decision to move the launch date include the impacts of augmented safety precautions, reduced on-site personnel, disruption to shift work and other technical challenges. Webb will use existing program funding to stay within its $8.8 billion development cost cap.

“Based on current projections, the program expects to complete the remaining work within the new schedule without requiring additional funds,” says Gregory Robinson, NASA Webb program director at the agency’s headquarters. “Although efficiency has been affected and there are challenges ahead, we have retired significant risk through the achievements and good schedule performance over the past year. After resuming full operations to prepare for upcoming final observatory system-level environmental testing this summer, major progress continues towards preparing this observatory for launch.” The project team will continue to complete a final set of extremely difficult environmental tests of the full observatory before it will be shipped to its launch site in Kourou, French Guiana, situated on the northeastern coast of South America.

This week, NASA says the project successfully completed electrical testing of the observatory. The test highlighted a major milestone in preparation for the upcoming acoustics and vibration environmental tests of the full observatory that are scheduled to start in August. In addition to ongoing deployments, ground system testing of the fully integrated observatory has followed immediately afterwards.

Related Content

Improving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

Successful tower extension test for James Webb space telescope

The test ensured the tower extensions on NASA’s composites-intensive telescope would keep the structure cool enough to detect infrared light.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More