NASA launches composite solar sail into space

Sunlight-based propulsion system, supported by carbon fiber-reinforced booms, will undergo weeks-long testing to demonstrate and verify its capabilities.

Share

Read Next

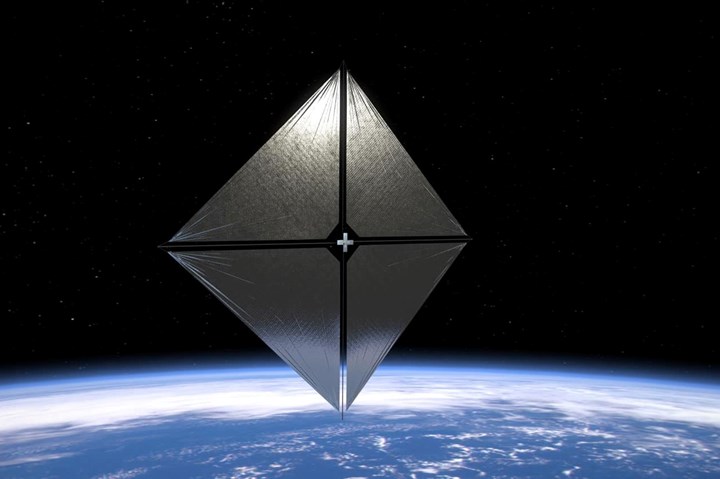

NASA’s (Washington, D.C., U.S.) mission to test a new way of navigating the solar system is underway. The space agency’s advanced composite solar sail system (ACS3) was launched to space on April 23 (April 24 in New Zealand) aboard a Rocket Lab (Colorado, Colo., U.S.) composites-intensive Electron rocket from the company’s Launch Complex 1 on the Mahia Peninsula of New Zealand.

The ACS3 features booms (which support and connect the sails to spacecraft) that are made from a polymer material that is flexible and reinforced with carbon fiber. The sails use “the pressure of sunlight for propulsion, angling toward or away from the sun so that photons bounce off the reflective sail to push a spacecraft,” according to NASA’s website. This eliminates heavy propulsion systems and could enable longer duration and lower cost missions (learn more about the sail and its development here).

Rocket Lab’s Electron rocket deployed the mission’s CubeSat about 600 miles above Earth — more than twice the altitude of the International Space Station (ISS). To test the performance of NASA’s ACS3 system, the spacecraft must be in a high enough orbit for the tiny force of sunlight on the sail — roughly equivalent to the weight of a paperclip resting on your palm — to overcome atmospheric drag and gain altitude.

After a busy initial flight phase, which will last about two months and includes subsystems checkout, the microwave oven-sized CubeSat will deploy its reflective solar sail. The weeks-long test consists of a series of pointing maneuvers to demonstrate orbit raising and lowering, using only the pressure of sunlight acting on the sail.

NASA’s Ames Research Center in California’s Silicon Valley manages the project and designed and built the onboard camera diagnostic system. NASA’s Langley Research Center in Langley, Virginia, designed and built the deployable composite booms and solar sail system. NASA’s Small Spacecraft Technology (SST) program office, within the agency’s Space Technology Mission Directorate (STMD), funds and manages the mission. STMD’s Game Changing Development program developed the deployable composite boom technology. Rocket Lab USA is providing launch services.

Related Content

-

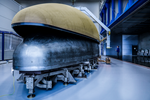

On the radar: Cryogenic testing of composites for future hydrogen storage

Netherlands, U.K., France, Germany and the U.S. build up test capability, look at thermoset and thermoplastic composite materials.

-

Airborne delivers composite upper stage tank for EU ENVOL project

Nine-member consortium targets development of low-cost, green vertical orbital launcher with manufacture of an ultra-lightweight composite tank design in an automated manufacturing environment.

-

HyImpulse, Adamant Composites linerless CFRP tank passes hydrostatic burst test

The liquid oxygen (LOX) tank, to be used in a HyImpulse smallsat launch vehicle, demonstrates the ability to withstand pressures well beyond the limits of its intended use.