NCC’s all-composite Type V tank demonstrates future composite space tank technology

SpaceTank project delivers a 96-liter carbon fiber composite tank with 4.0-5.50-millimeter nominal wall thickness for 30% weight savings in launch vehicle and satellite propellant tank applications.

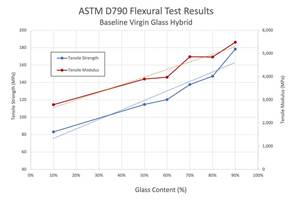

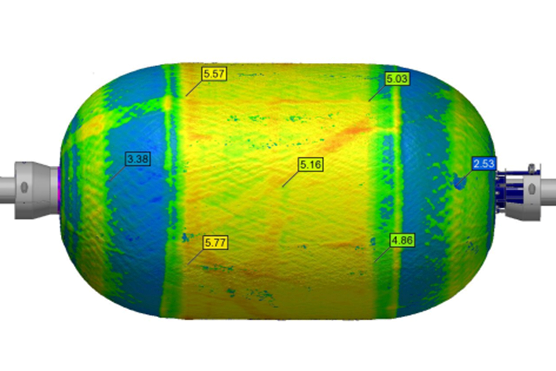

SpaceTank thickness. Photo Credit, all images: The NCC

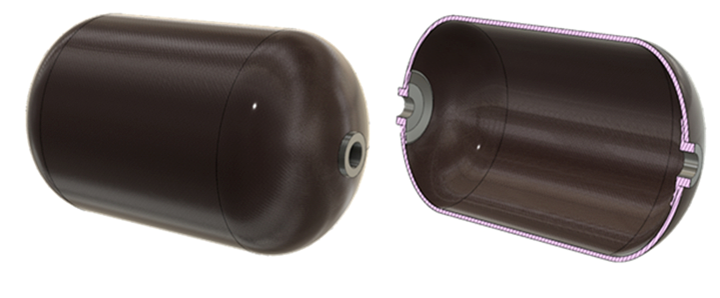

The National Composites Centre (NCC, Bristol, U.K.), with industry guidance from aerospace manufacturer Thales Alenia Space (Cannes, France), has manufactured an all-composites linerless (Type V) tank demonstrator under the SpaceTank project. It is said to be representative of those used for launch vehicle and satellite propellant tanks, delivering an estimated weight saving of 30% compared to conventional metallic propellant tanks in current use. The NCC has demonstrated this to engage U.K. interest in the manufacture of composite tanks for future space propulsion needs. According to the NCC, this showcase project demonstrates how advanced composites technology can play a vital role on future engineered structures in space propulsion by reducing the structural weight of the tank and lowering satellite launch costs (download PDF of the case study).

The overall aim for the SpaceTank project was to develop U.K.-based research and development tools necessary for the manufacture and inspection of cryogenic pressure vessels. More specifically, the one-year project focused on developing a new manufacturing solution for tanks to hold cryogenic propellants.

The space industry recognizes the critical role of composite materials in space, with some companies already exploring their use in space tank design. For example, Virgin Orbit (Long Beach, Calif., U.S.) and RocketLab (Auckland, New Zealand) have both developed and demonstrated composite tanks as alternatives to metal for the Launcher One and Electron rockets respectively. In Australia, Omni Tanker (Smeaton Grange) and partners are seeking to develop and commercialize a composite linerless liquid hydrogen tank (LH2), and closer to home in Europe, MT Aerospace (Augsburg, Germany) is developing materials and manufacturing methods and undergoing tests for a novel new rocket fuel tank. The NCC SpaceTank project is expected to level up the U.K. as a key player in this field.

The tooling technique led to the development of a casting process in partnership with AeroConsultants using the company’s Aqua water-soluble core material.

The NCC SpaceTank demonstrator created is 750 millimeters long, has a diameter of 450 millimeters and a fluid storage capacity of more than 96 liters. It has been designed and manufactured with a nominal wall thickness of 4.0-5.5 millimeters, which enables the tank to withstand 85 bar of pressured propellant. The carbon fiber composite main body comprises of 8 kilograms of material mass, but according to the NCC, as with all engineered structures, there are further opportunities with SpaceTank to optimize this weight reduction further. Moreover, the pressure rating of the NCC SpaceTank can be increased with the use of higher strength carbon fibers and by increasing the composite thickness. Alternatively, the SpaceTank could be optimized for weight and cost for much lower pressure applications by using a thinner and lower stiffness composite material.

During the SpaceTank project, the NCC team developed an innovative method for including the metal fluid valve ports to the washable tool, to remove the need for any secondary assembly and bonding operations needed for the final product. These fluid valve ports were held in the novel tooling, enabling them to be co-bonded to the carbon fiber during the latter stage of the manufacturing process.

The tank’s main body uses MTC510 epoxy carbon fiber prepreg supplied by SHD Composites (Sleaford, U.K.) in a 300-millimeter tape width. MTC510 is an epoxy resin system that is specifically designed to cure between 80°C and 120°C and is toughened to increase its damage tolerance.

This material was prepared for the SpaceTank manufacturing process by Bindatex (Bolton, U.K.), which also performed narrow width precision slitting of the tape and returned 22,000 meters (approximately 72,178 feet) of the material in a 6.35-millimeter format prepared in accordance with the NCC’s requirement for use in its Coriolis (Queven, France) automated fiber placement (AFP) manufacturing cell.

The slit tape was deposited onto the washable tooling using the Coriolis AFP system’s tensioned filament winding operation. A combination of helical and hoop winding designed by the NCC engineers using Material’s Cadwind (Brussels, Belgium) filament winding software was used to deposit more than 24 layers of the material to a nominal 5.5-millimeter thickness. The thickness and direction/angle of winding used here was for demonstration only; it is possible for the NCC to either increase or decrease the composite wall thickness and alter the winding angle and ply structure to fully optimize the tank for a specific pressure or loading requirement.

Immediately after the material deposition, the NCC SpaceTank was inspected for defects and thickness variation. It was then autoclave cured at 100°C and re-inspected afterwards. Ultrasonic C-Scanning and thermography non-destructive test (NDT) inspection techniques were used after curing, and these methods compared and contrasted for suitability of inspecting future tanks for defects such as delamination and porosity. Finally, after completing the NDT quality assessment, the internal tooling core was washed out with pressurized cool water to leave the inner tank cavity empty.

Rendered space tank.

According to the NCC, the tooling technique for the linerless SpaceTank proved to be difficult, which led to the development of a casting process in partnership with AeroConsultants (Huntingdon, U.K.) using the company’s Aqua water-soluble core material. The finished tool features a centralized male core with a nominal 30-millimeter wall thickness which is cast in two parts and then bonded. The tool has three (washable) internal stiffening rings which were designed and manufactured to help withstand the torsion loading expected during the automated composite layup and the pressure exerted during the autoclave curing.

This demonstration by the NCC now provides a research foundation in the U.K. for future propellant tank development and helps support a new U.K. supply chain for state-of-the-art components and equipment for composite tanks manufacturing.

Future research activity in this area will also reportedly support the increase of the U.K.’s 5% share of the global space economy. A report from the UK government in May 2021 showed that the U.K.’s space industry income increased from £14.8 billion in 2016/2017 to £16.4 billion in 2018/2019. The summary report for the UK Space Agency also highlighted that more than 3,000 jobs have been created within the U.K. space sector over last two years (2019-2021).

Related Content

Pilot program turns EOL wind blades to liners for pipe infrastructure

TPI Composites, Tex-Tech and Carbon Rivers partner to process wind blades, pyrolyze the material and use the recovered glass fibers to give new life to damaged existing pipelines.

Read MoreDLR completes MFFD upper shell skin layup

Eight-meter-long CFRTP fuselage skin was achieved via laser-heated in-situ consolidation, with stringers, frames and cleats to be welded.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreCorebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More